Extraction method of humic acid

An extraction method, humic acid technology, applied in the direction of organic fertilizers, etc., can solve problems such as poor effect, high cost, accumulation system, etc., and achieve the effect of solving pollution control problems, low operating costs, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

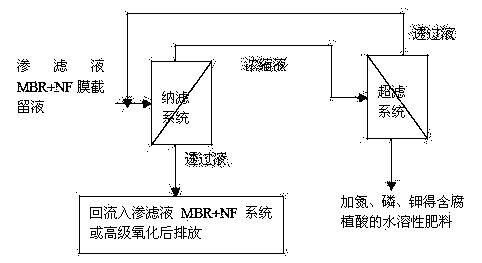

Image

Examples

Embodiment 1

[0018] Humic acid extraction method technical parameters in leachate MBR+NF membrane retentate of the present invention:

[0019] 1. Water quality conditions of leachate MBR+NF membrane retentate

[0020] pH 6.0~8.0

[0021] COD cr 1500~8000mg / L

[0022] BOD 5 <50mg / L

[0023] TDS 10000~15000mg / L

[0024] 2. Nanofiltration system

[0025] Working pressure 0.6~1.8MPa

[0026] Concentration times 1.5~5 times

[0027]Molecular weight cut off 150~500Da

[0028] 3. Ultrafiltration system

[0029] Working pressure 0.8~1.8MPa

[0030] Concentration times 5~10 times

[0031] Molecular weight cut off 500~1000Da

[0032] Humic acid ≥30g / L

Embodiment 2

[0034] The sanitary landfill started operation in 2002, with a daily production of 150 tons of leachate. The water quality is as follows: pH is 8.0~8.8, COD cr 1800~2800mg / L, BOD 5 The concentration of heavy metals is 400~780mg / L, the conductivity is 13.2~18.1ms / cm, the concentration of heavy metals is lower than the primary discharge standard, and the color is grayish black to yellow. The leachate main treatment system adopts MBR+NF process, and the effluent reaches the first-class discharge standard stably. The water quality of the leachate MBR+NF membrane retentate is: pH 6.5~8.0, COD cr The concentration of humic acid is 2500~3300mg / L, the concentration of humic acid is about 1700~2300mg / L, and the TDS is 13000~14000mg / L. The membrane retentate can be directly lifted by the pump into the nanofiltration system. The relative molecular weight cut-off (MWCO) of the nanofiltration membrane is 150~500, the operating pressure difference is 0.6~1.8Mpa, and the concentration rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com