A kind of porous solid amine and preparation method thereof

A porous solid and polyamine technology, applied in the field of compounds, can solve the problems that porous solid amines have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

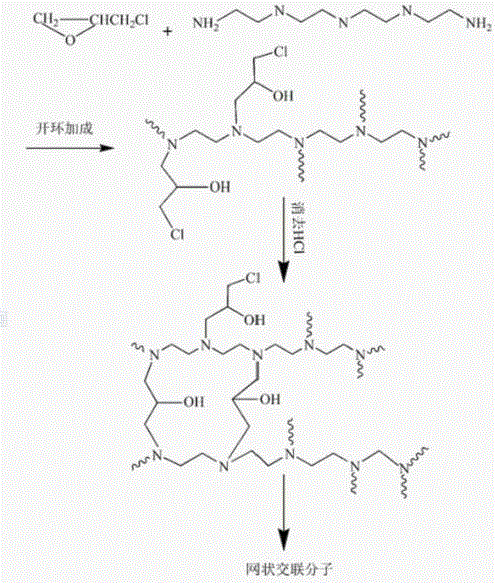

Method used

Image

Examples

Embodiment 1

[0023] Set the ratio of raw materials, the molar ratio of tetraethylenepentamine, epichlorohydrin and boric acid is 1:1:1. Take a clean 250mL beaker, weigh 3.0981g of boric acid with an electronic balance, measure 9.5mL of tetraethylenepentamine with a 10mL measuring cylinder, and stir continuously with a glass rod until a white paste is formed (boric acid no longer presents crystalline state), cool Stir for a while. Place in a ventilated place, pour 3.8mL of epichlorohydrin, and continue stirring until the reaction occurs. The rapid expansion of the liquid reactant to a spongy solid accompanied by gas evolution was observed.

Embodiment 2

[0025] Set the ratio of raw materials, the molar ratio of triethylenetetramine: boric acid: epichlorohydrin is 1:1:1.

[0026] Take a clean 250mL beaker according to the above ratio of 1:1:1, weigh 3.0981g of boric acid with an electronic balance, measure 7.3mL of triethylenetetramine with a 10mL graduated cylinder, and stir continuously with a glass rod until a white paste ( Boric acid is no longer crystalline), cooled and stirred for a while. Place in a ventilated place, pour 3.8mL of epichlorohydrin, and continue stirring until the reaction occurs. The rapid expansion of the liquid reactant to a spongy solid accompanied by gas evolution was observed.

Embodiment 3

[0028] The ratio of raw materials is set, and the molar ratio of diethylenetriamine: boric acid: epichlorohydrin is 1:1:1.

[0029] Take a clean 250mL beaker according to the above ratio of 1:1:1, weigh 3.0981g of boric acid with an electronic balance, measure 5.3mL of diethylene triethylene with a 10mL graduated cylinder, and stir continuously with a glass rod until a white paste (boric acid no longer present crystalline state), cooled and stirred for a while. Place in a ventilated place, pour 3.8mL of epichlorohydrin, and continue stirring until the reaction occurs. The rapid expansion of the liquid reactant to a spongy solid accompanied by gas evolution was observed.

[0030] The synthesized porous amine solid product can be used to measure its amine group content by acid-base calibration method, such as oxalic acid (H 2 C 2 o 4 2H 2 O) calibrate the number of amine groups per gram of porous solid amine, such as the number of amine groups contained in every gram of sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com