A kind of supercapacitor electrode material, preparation method and application

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. Capacitive performance, the effect of excellent specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

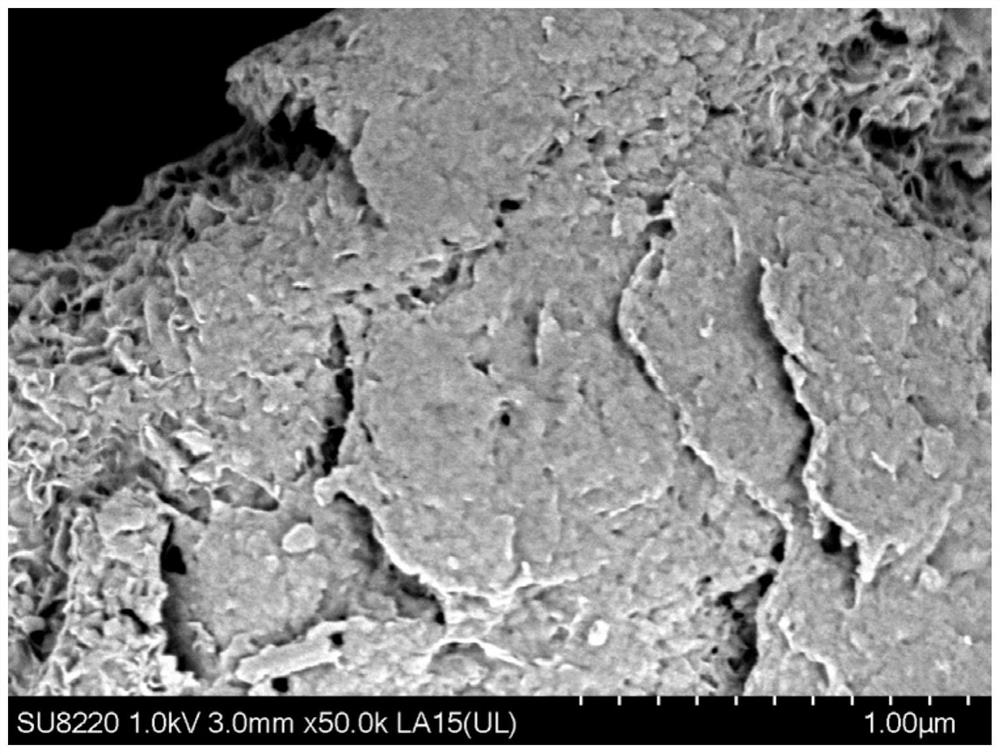

Image

Examples

Embodiment 1

[0032] The preparation method of the present embodiment 1 metal hydroxide film material comprises the following steps:

[0033] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 9 mmol of triethanolamine was added dropwise, and after stirring for 20 min, the obtained mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 12 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

Embodiment 2

[0035] The preparation method of the present embodiment 2 metal hydroxide film material comprises the following steps:

[0036] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 12 mmol of triethanolamine was added dropwise, and after stirring for 20 min, the obtained mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 12 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

Embodiment 3

[0038] The preparation method of the present embodiment 3 metal hydroxide film material, comprises the following steps:

[0039] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 9 mmol of triethanolamine was added dropwise, and after stirring for 20 min, the obtained mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 8 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com