Method for increasing coiling temperature control accuracy of low temperature steel

A technology of coiling temperature and control accuracy, which is used in temperature control, metal rolling, manufacturing tools, etc. Some functions of the temperature model cannot be put into normal operation, etc., to achieve the effect of reducing the number of coils with different properties, stably controlling the coiling temperature model, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for improving the temperature control accuracy of low-temperature steel coiling according to the present invention uses a laminar flow cooling device to cool the steel strip, and mainly adopts the following process steps (the temperature mentioned in the embodiments of the present invention refers to degrees Celsius):

[0027] 1) Equipment configuration: add a coiling pyrometer with a measurement range of 0-1000 degrees at the outlet of the cooling zone before coiling, and configure a fan for the pyrometer;

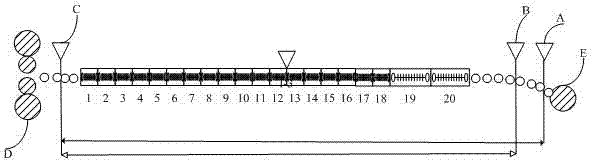

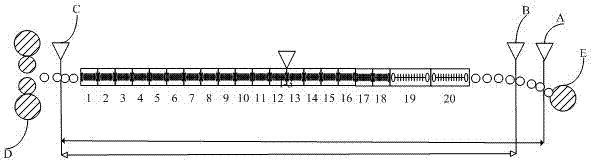

[0028] see figure 1As shown, the figure shows the pyrometer and equipment layout in the cooling zone from the finish rolling exit to the underground coiler; there is a pyrometer C in the cooling zone adjacent to the finish rolling exit of the finish rolling machine tool D, close to the underground coiler A coiling pyrometer A with a measuring range of 0-1000 degrees is provided 13m behind the coiling pyrometer B with a measuring range of 300-1100 degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com