Computing method for equivalent elastic modulus of two-dimensional porous materials

A technology of equivalent elastic modulus and porous materials, applied in computing, special data processing applications, instruments, etc., can solve problems such as difficult application, complex application of periodic loads, unsuitable equivalent elastic modulus of two-dimensional porous materials, etc. , to achieve the effect of small amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Hexagonal 2D porous material along x1 、x 2 and x 3 The equivalent modulus of elasticity in the direction.

[0027] Such as figure 2 In the structure of the hexagonal two-dimensional porous material shown, each characteristic unit has 4 oblique pore walls with length d and thickness t and 2 vertical pore walls with length h and thickness t, and the pore depths are all b. x 1 The axis is perpendicular to the vertical hole wall, x 2 Axis parallel to the vertical hole wall, and x 3 The axis is along the direction of the hole depth. The wall surface of the hypotenuse hole and x 1 -x 3 The included angle of the faces is θ, which is defined as the spread angle. In this embodiment, the base material is aluminum alloy, and its physical parameters related to linear elastic deformation are: Young's modulus E s = 68.97GPa, Poisson's ratio v s =0.35, density ρ s =2700Kg / m 3 .

[0028] Step 1. Use ANSYS / Multiphysics software to establish a hexagonal two-dimensional poro...

Embodiment 2

[0045] Calculation of Coplanar Equivalent Elastic Modulus of Triangular Two-Dimensional Porous Materials

[0046] In this embodiment, the base material is aluminum alloy, and its physical parameters related to the linear elastic stage are: Young's modulus is E s =68.97GPa, Poisson's ratio is v s =0.35, the density is ρ s =2700Kg / m 3 .

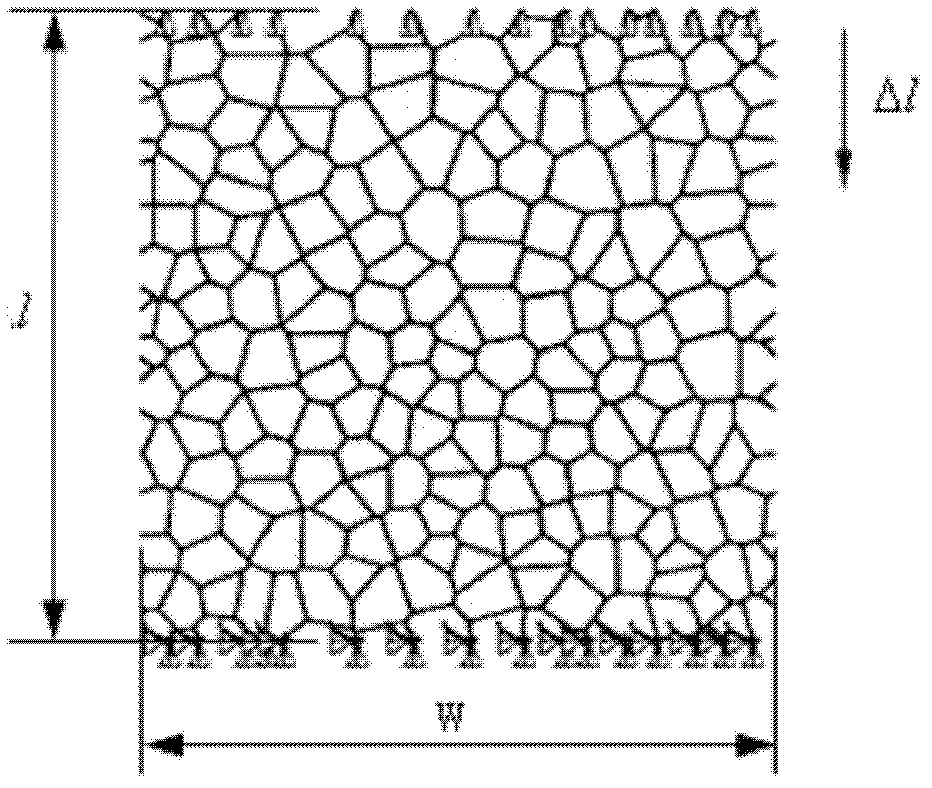

[0047] ANSYS / Multiphysics software was used to establish the finite element calculation model of the two-dimensional porous material, and the model was obtained as follows: Figure 7 shown, along the l 1 The direction is called coplanar, and the coplanar equivalent elastic modulus is defined as E 1 * . The side length of the triangle in the periodic feature unit is 5mm, the base angle is 60°, and the wall thickness is 0.15mm. According to the ASTM tensile test standard, the number of complete elements in the length and width directions of the two-dimensional porous material finite element calculation model should be m 1 = 51 and n 1 =...

Embodiment 3

[0052] Calculation of Coplanar Equivalent Elastic Modulus of Square Two-Dimensional Porous Materials

[0053] In this embodiment, the base material is aluminum alloy, and its physical parameters related to the linear elastic stage are: Young's modulus is E s =68.97GPa, Poisson's ratio is v s =0.35, the density is ρ s =2700Kg / m 3 .

[0054] ANSYS / Multiphysics software was used to establish the finite element calculation model of the two-dimensional porous material, and the model was obtained as follows: Figure 8 shown, along the l 1 The direction is called coplanar, and the coplanar equivalent elastic modulus is defined as E 1 * . The side length of the square in the periodic feature unit is 5mm, and the wall thickness is 0.15mm. According to the ASTM tensile test standard, the number of complete elements in the length and width directions of the two-dimensional porous material finite element calculation model should be m 1 = 44 and n 1 =26, then the length l of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com