Optical lens center thickness measuring system and method

A technology of center thickness and optical lens, applied in measuring devices, optical devices, instruments, etc., can solve the problems of surface damage, unusability, inaccuracy of optical components, etc., to ensure accuracy, good feasibility, and simple measurement. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

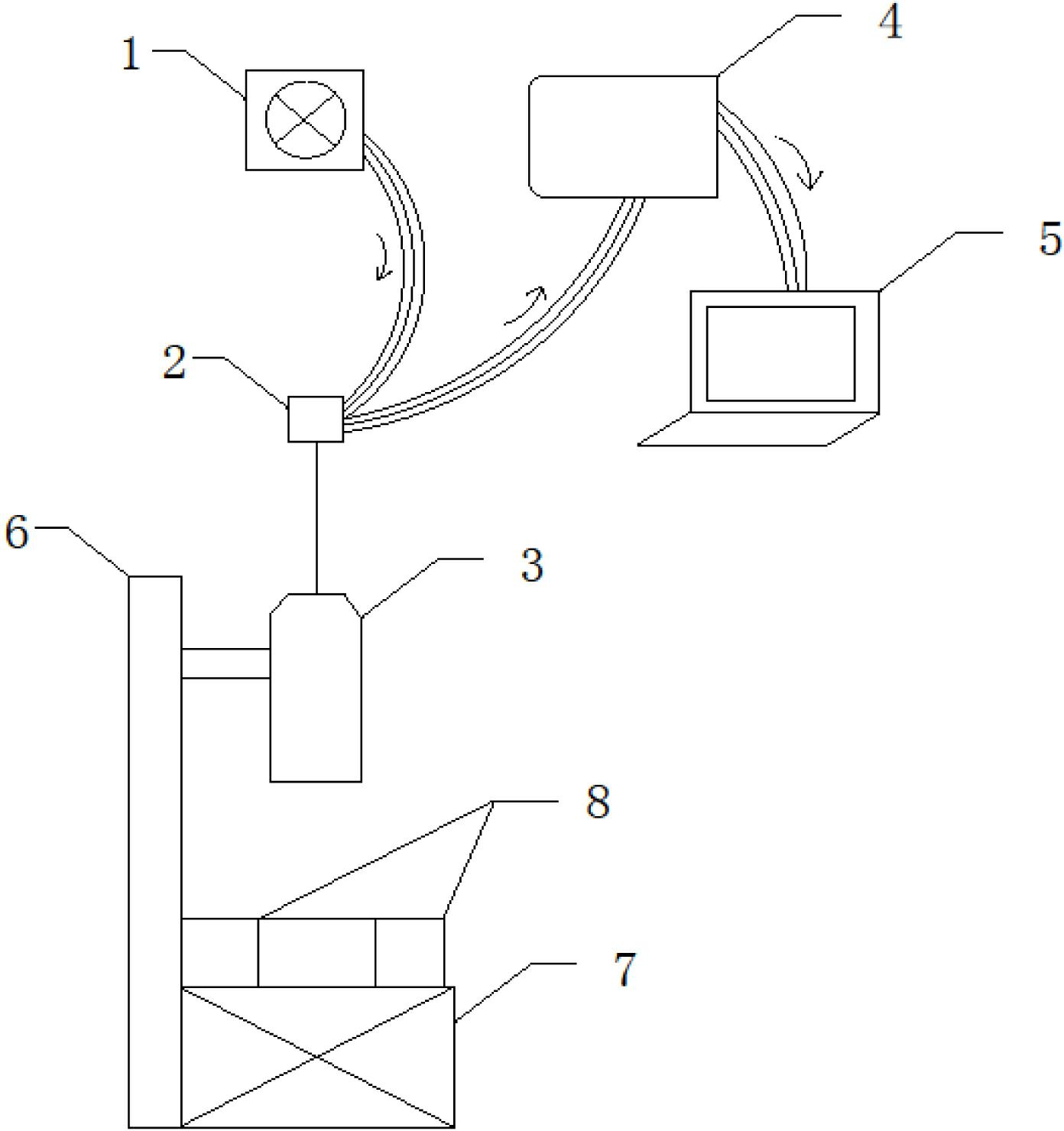

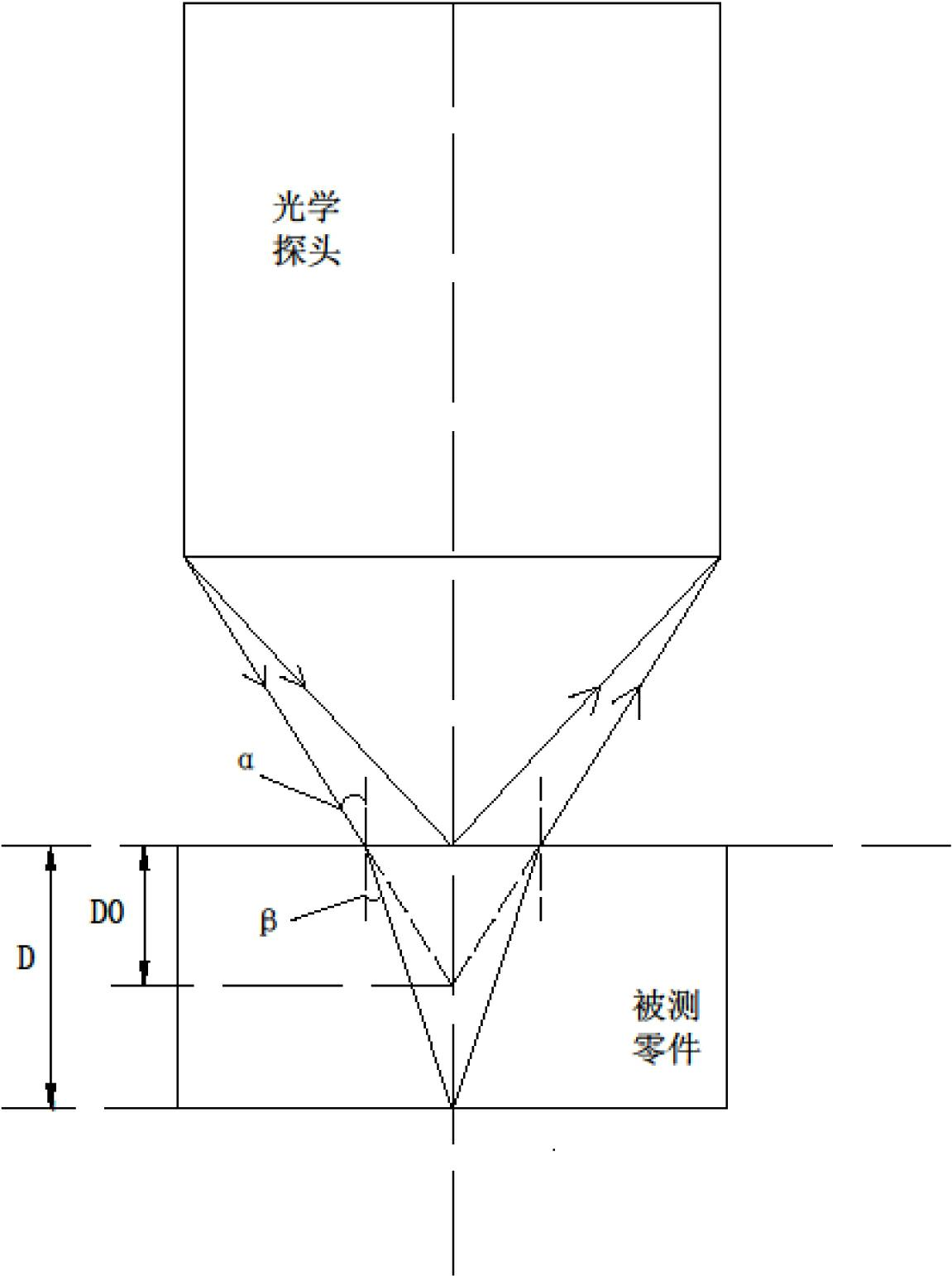

[0032] refer to figure 1 , optical lens center thickness measurement system, including a light source, also includes a spectroscopic device, an optical probe, a spectrometer and a computer, the light source is connected to the spectroscopic device, the spectroscopic device and the optical probe are facing and centered on the same axis, one end of the spectroscopic device A spectrometer is also connected, and the spectrometer is connected to a computer.

[0033] As a further preferred implementation manner, an aspheric optical system is arranged inside the optical probe.

[0034] As a further preferred embodiment, it also includes a support frame for fixing the optical probe, an object stage and a fixture for fixing the measured part.

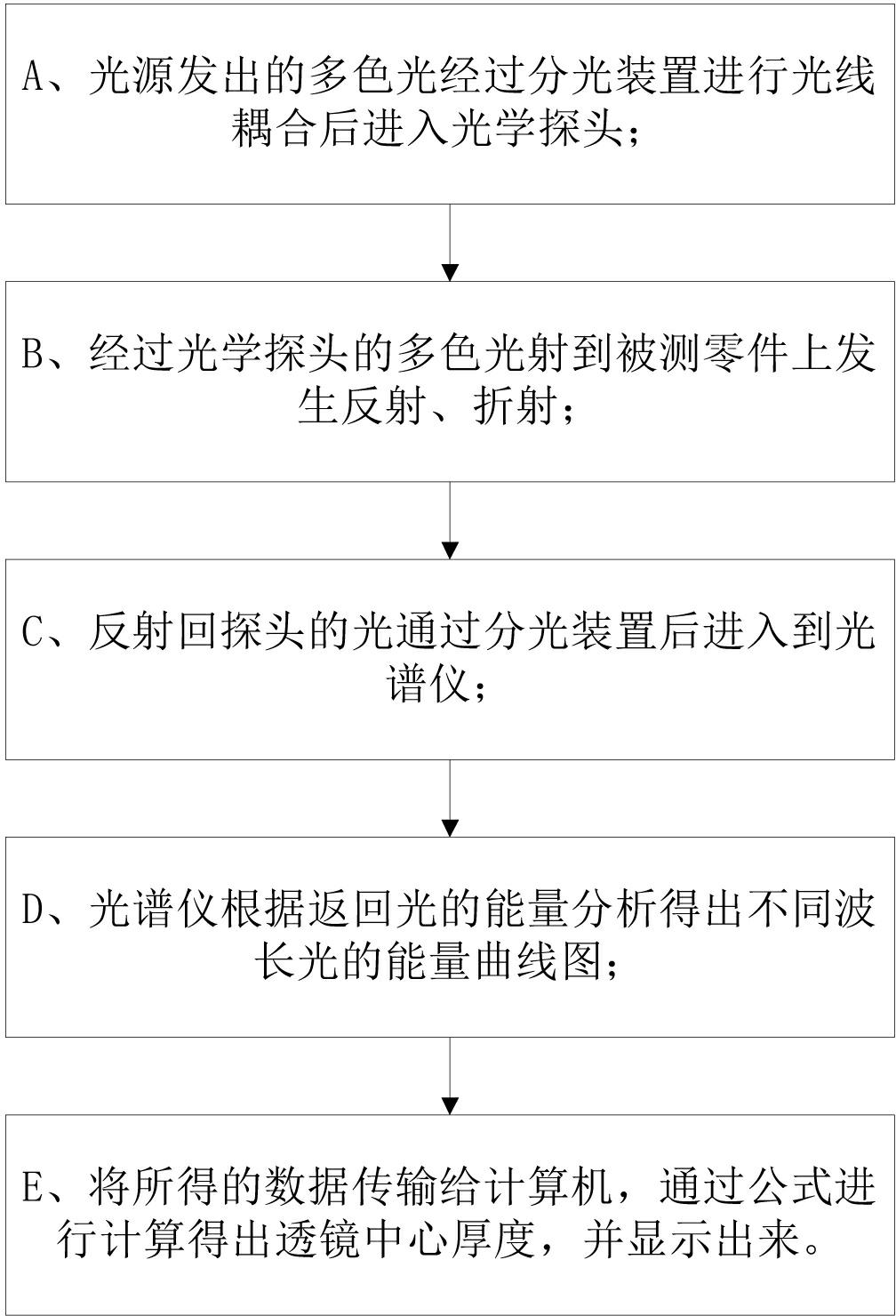

[0035] refer to figure 2 , optical lens center thickness measurement method, comprises the following steps:

[0036] A. The polychromatic light emitted by the light source enters the optical probe after being coupled by the spectroscopic dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com