Integrated condenser

A condenser, all-in-one technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as large total volume and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

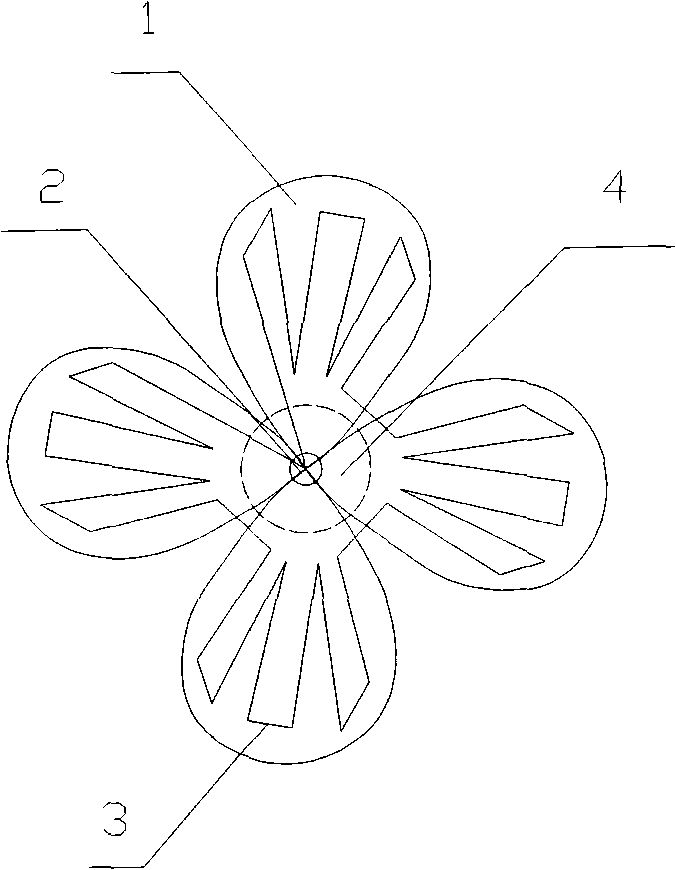

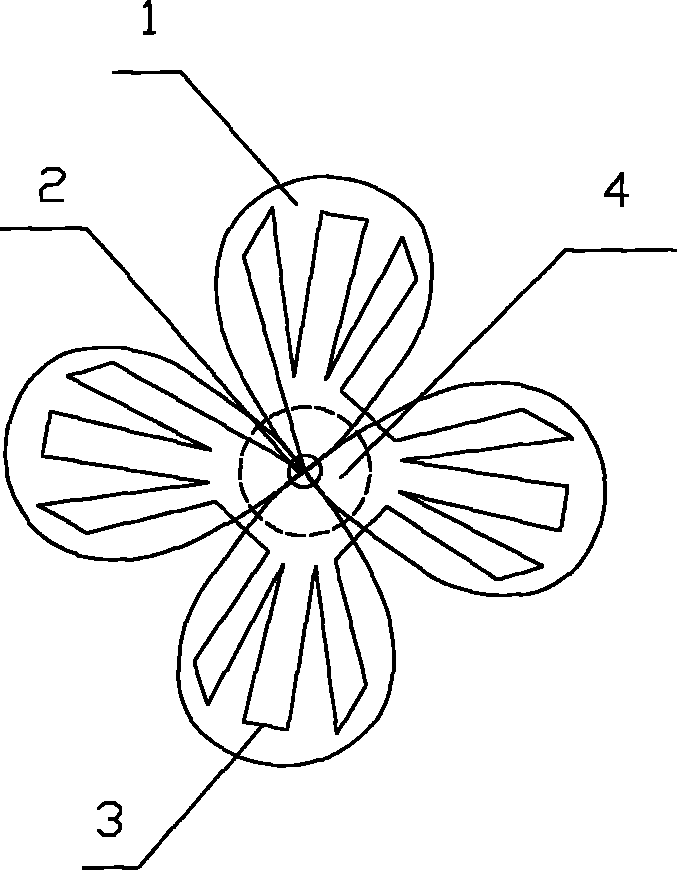

[0009] In the specific embodiment shown in the accompanying drawings, the integrated condenser consists of a fan blade (1), a rotating shaft and a bracket

[0010] (2), consisting of heat dissipation copper tube (3) and motor (4), among which the fan blades (1) have 3-4 pieces in total, made of aluminum sheet to make the fan blade shape of a common fan, and the heat dissipation copper tube (3) is clamped in the middle The part of the heat dissipation copper pipe (3) is divided into 3-4 parts, and each part is clamped on each fan blade (1) in a repeated circuitous curve. , each part of the cooling copper tube (3) is seamlessly connected in series, and its overall outlet and inlet are led out from the center of the rotating shaft of the fan blade to the rear of the fan blade, and the motor (4) directly drives each fan blade (1) to rotate. With the operation of the heat pump unit, the motor (4) drives the fan blades (1) to rotate, and the cold air directly passes over the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com