Drill rod assembling and disassembling mechanical arm of myriameter well drill

A technology for manipulators and drilling machines, applied in drill pipes, drilling equipment, drill pipes, etc., can solve the problems of high cost, large volume, poor structural flexibility, etc., and achieve convenient transportation and station transfer, flexible and accurate movement, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

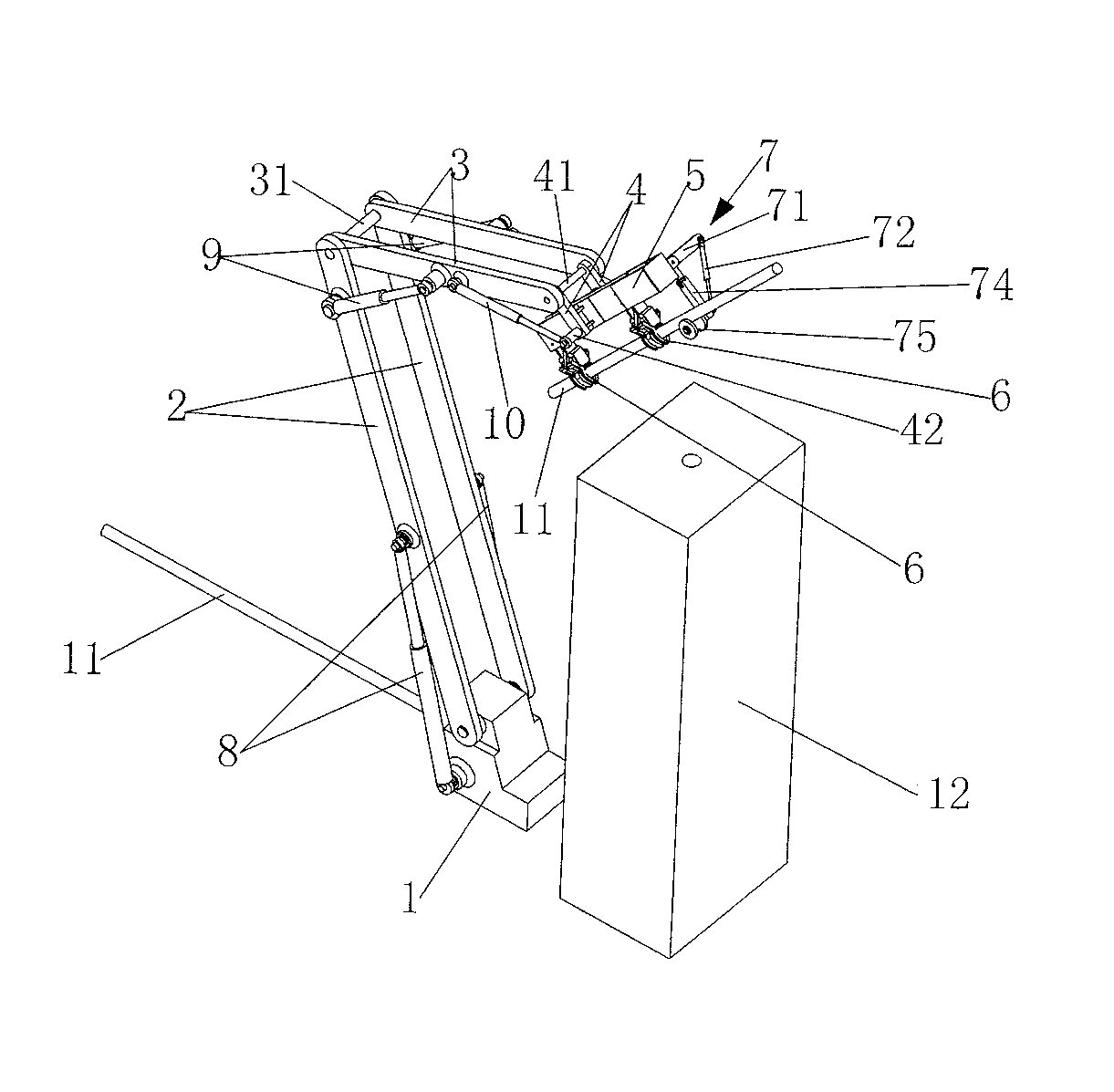

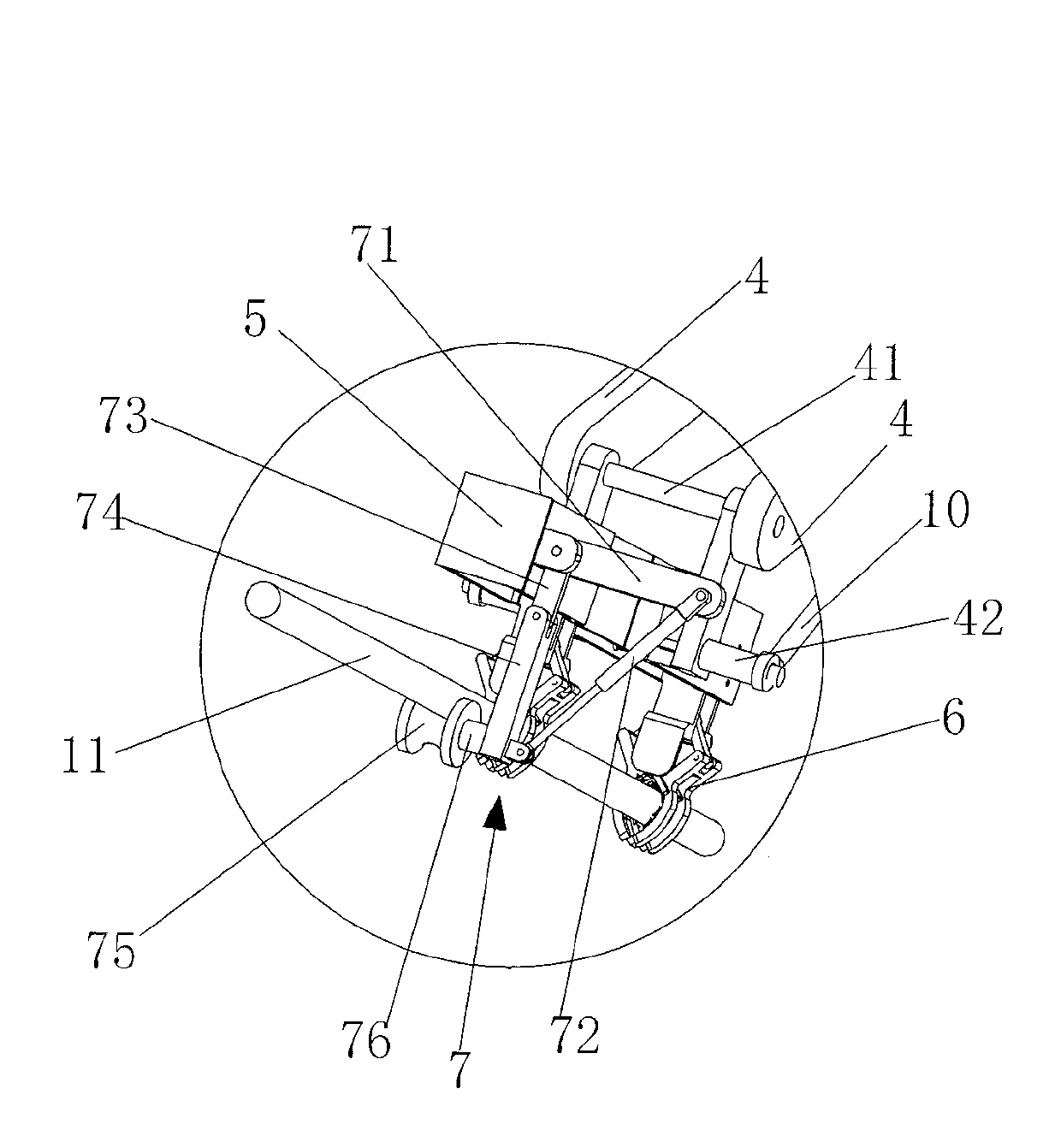

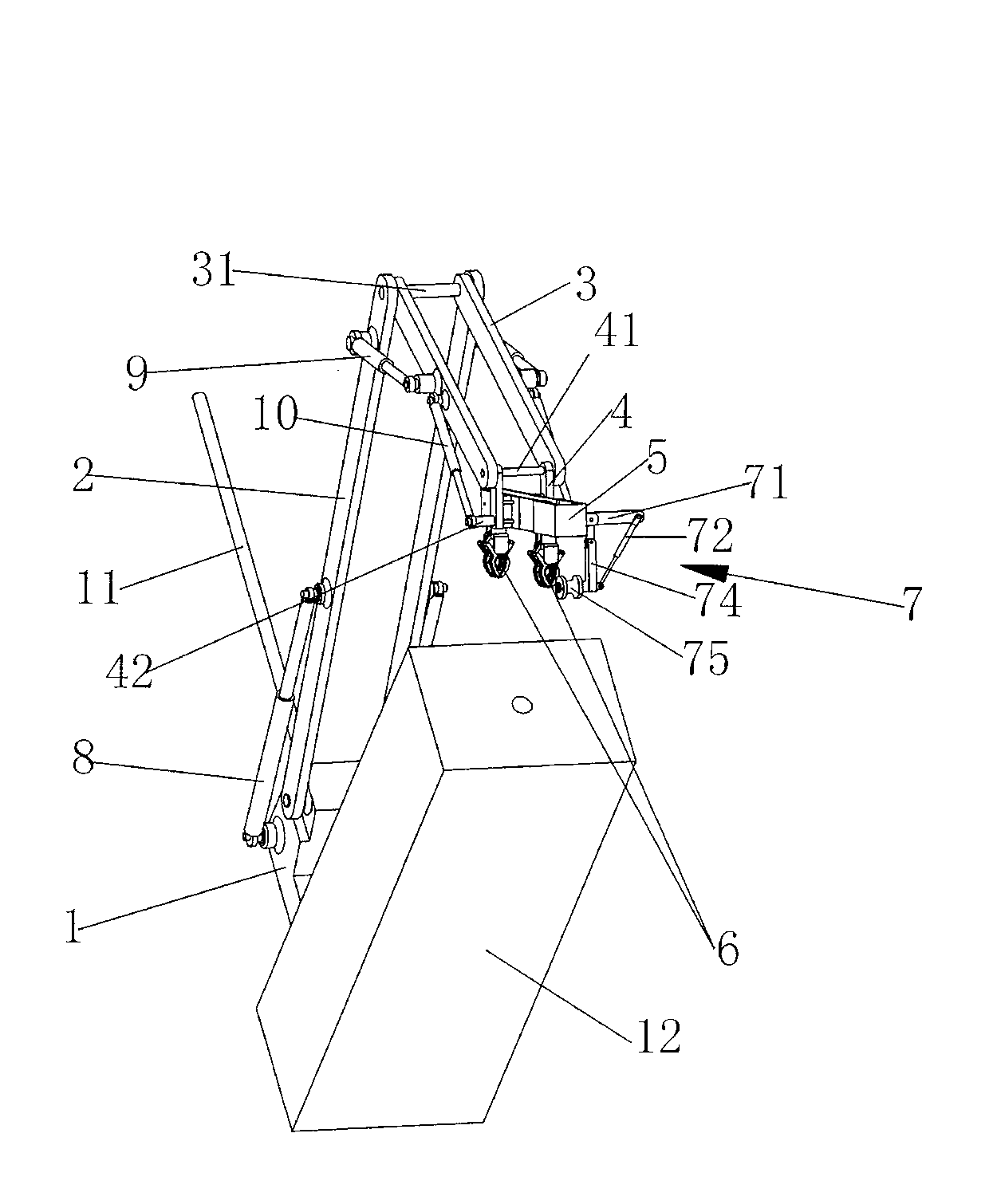

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, the present invention is made of base 1, two first connecting rods 2, two second connecting rods 3, two third connecting rods 4, suspension beam 5, two mechanical grippers 6, pipe supporting mechanism 7, two One first hydraulic cylinder 8, two second hydraulic cylinders 9 and two third hydraulic cylinders 10, the lower ends of the two first connecting rods 2 are hinged on the left and right sides of the base 1, the lower ends of the two second connecting rods 3 The shafts 31 are hinged on the inner sides of the upper ends of the two first connecting rods 2, the lower ends of the two third connecting rods 4 are hinged on the inner sides of the upper ends of the two second connecting rods 3 by shafts 41, and the upper ends of the two third connecting rods 4 The inner side fixes the suspension beam 5 along the direction, and the bottom of the suspension beam 5 is provided with two mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com