Reactive black dye mixture

A technology of black dyes and mixtures, applied in organic dyes, dyeing methods, textiles and papermaking, etc., which can solve problems such as excessive dependence on color quantity, poor dyeing performance of dyes, and high application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

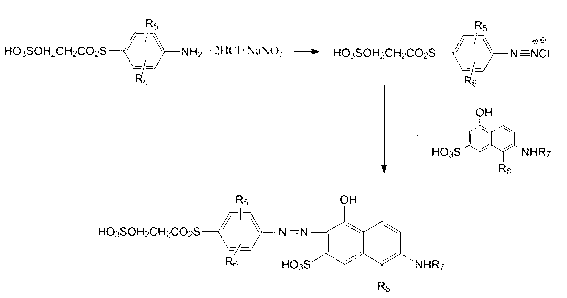

[0038] Put 28.1 parts of 4-(β-hydroxyethyl sulfone) sulfate aniline into the reactor, add 100 parts of water and 50 parts of ice, and add 13 parts of industrial hydrochloric acid and 6.9 parts of sodium nitrite under high-speed stirring to fully react to obtain diazo salt; then add 17 parts of 1-amino-8-naphthol-3,6-disulfonic acid (H acid) to the diazonium salt reaction liquid, under the conditions of T=5-8℃, pH=0.5-2 carry out acidic coupling reaction at low temperature for 5 hours; finally add sodium bicarbonate solution at a temperature lower than 15°C to adjust pH=5-5.5, and continue the reaction for 2 hours to obtain reactive black dye (1) with structural formula (1).

[0039]

[0040] (1)

Embodiment 2

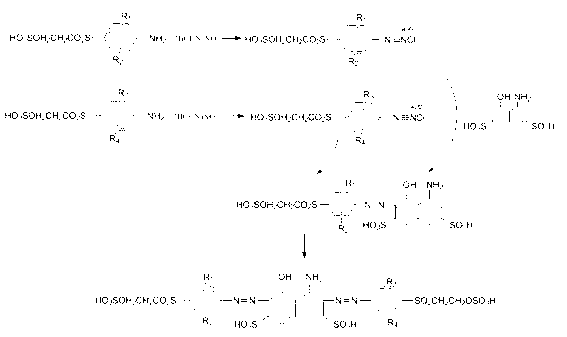

[0042] Put 28.1 parts of 4-(β-hydroxyethylsulfone)sulfate benzene and 31.8 parts of 2-chloro-4-(β-hydroxyethylsulfone)sulfate aniline into the reactor, add 200 parts of water and 100 parts of ice, and stir at high speed Next, add 28 parts of industrial hydrochloric acid and 13.8 parts of sodium nitrite to fully react to obtain diazonium salt; then add 1-amino-8-naphthol-3,6-bissulfonic acid (H acid ) 34 parts, carry out acidic coupling reaction for 5 hours under the conditions of T=5-8℃, pH=0.5-2; finally add sodium bicarbonate solution at a temperature lower than 15℃ to adjust pH=5-5.5, continue Reactive black dye (2) with structural formula (2) was obtained after reacting for 2 hours.

[0043]

[0044] (2)

Embodiment 3

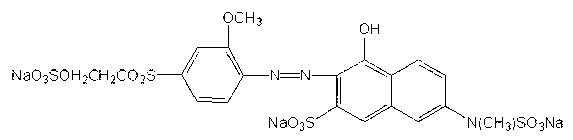

[0046] Put 28.1 parts of 4-(β hydroxyethyl sulfone)sulfate benzene and 31.1 parts of 2-methoxy-4-(β hydroxyethyl sulfone) sulfate aniline into the reactor, add 200 parts of water and 100 parts of ice, in Under high-speed stirring, add 28 parts of industrial hydrochloric acid and 13.8 parts of sodium nitrite to fully react to obtain diazonium salt; then add 1-amino-8-naphthol-3,6-disulfonic acid ( H acid) 34 parts, carry out acidic coupling reaction for 5 hours under the conditions of T=5-8℃, pH=0.5-2; finally add sodium bicarbonate solution at a temperature lower than 15℃ to adjust pH=5-5.5 , continue to react for 2 hours to obtain the reactive black dye (3) with the structural formula (3).

[0047]

[0048] (3)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com