Method for extracting and separating rosmarinic acid and ursolic acid from rosemary

A technology of rosmarinic acid and rosemary, which is applied in the separation/purification of carboxylate, steroids, organic chemistry, etc., can solve the problems of low yield, low cost, large content of active ingredients, etc. The effect of reducing production cost, simple operation and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

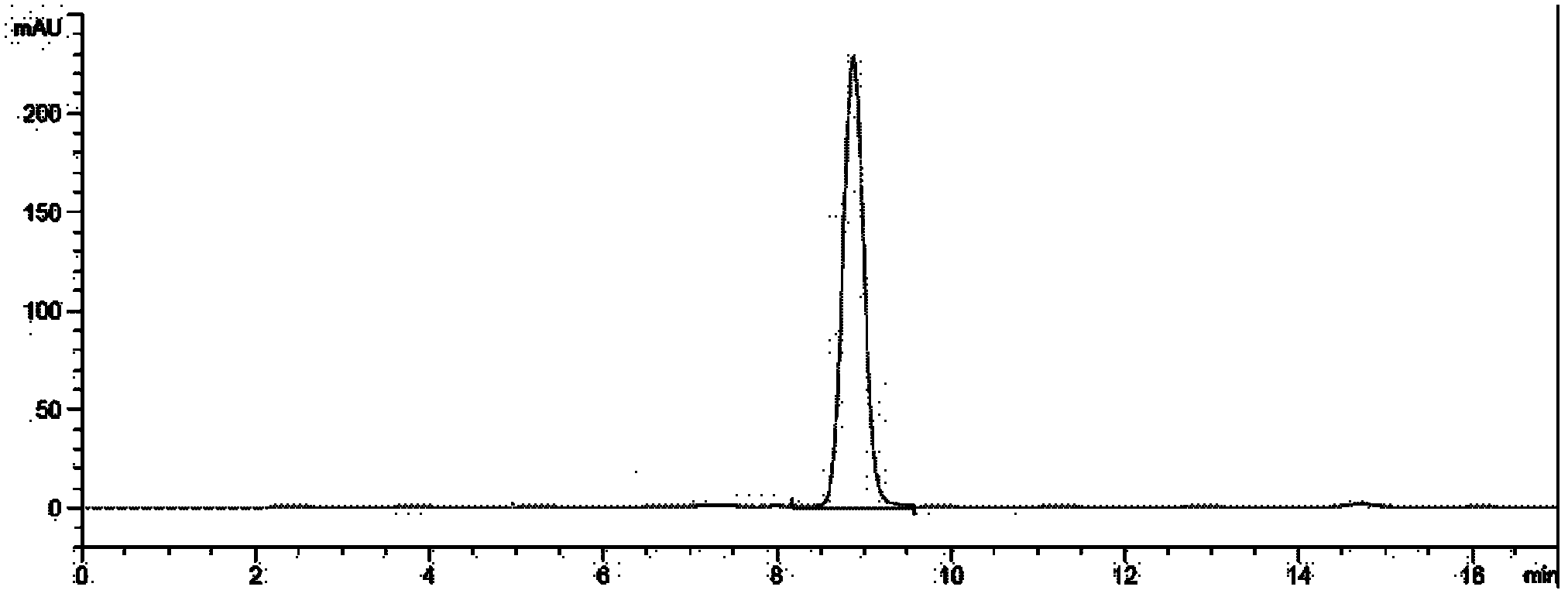

[0048] Weigh 100Kg of rosemary, pulverize it, place it in 300L (V / V) in 60% ethanol for 4 hours under vacuum at 40°C, filter it once with a ceramic membrane; add the filter residue to 200L of 60% ethanol, keep it under vacuum at 40°C for 4 hours, and then filter the The membrane was filtered once more, and the two filtrates were combined; the filtrate was added with an appropriate amount of antioxidant 150g and concentrated in vacuo at 50°C until 12kg of dry matter was obtained; 60L of 30% ethanol was used to dissolve the obtained dry matter, and the ceramic membrane was filtered once, and the filtrate was filtered. LSA-10 macroporous resin column, after adsorption, remove impurities with 60L petroleum ether and 60L ethyl acetate respectively, desorb with 60L pH3.5, 45% ethanol solution, and collect the eluate A; 16L of acetone was dissolved, filtered, and the filtrate was placed on an LSA-10 macroporous resin column. After adsorption, it was decontaminated with petroleum ether...

Embodiment 2

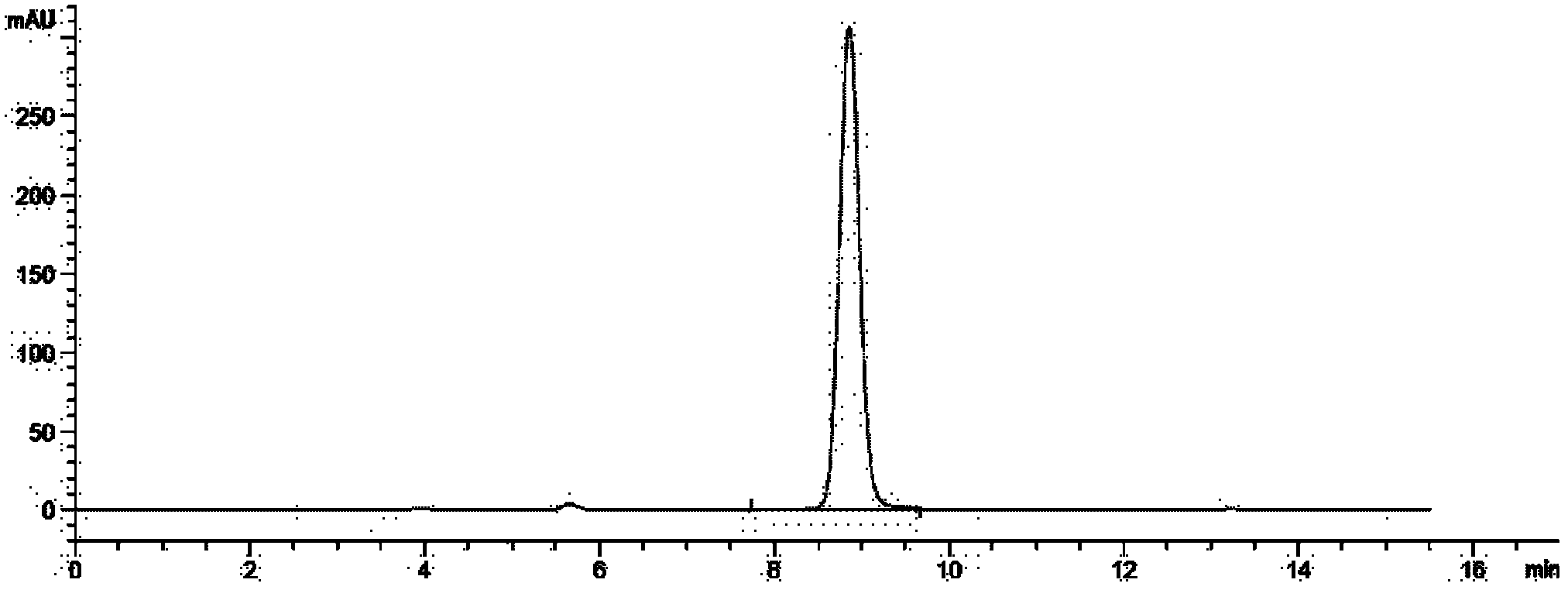

[0050] Weigh 200Kg of rosemary, pulverize it, place it in 600L (V / V) in 60% ethanol for 4 hours under vacuum at 40°C, filter it once with a ceramic membrane; add the filter residue to 400L of 60% ethanol, keep it under vacuum at 40°C for 4h, and then filter the The membrane was filtered once again, and the filtrates were combined twice; the filtrate was added with an appropriate amount of antioxidant 250g and concentrated in a vacuum at 50 ° C until 25kg of dry matter was obtained; the obtained dry matter was dissolved with 125L of 30% ethanol, and activated carbon was added to decolorize the ceramic for 15min. The membrane was filtered once, and the filtrate was applied to LSA-10 macroporous resin column. After adsorption, 120L of petroleum ether and 120L of ethyl acetate were used to remove impurities, and 120L of pH3.5, 45% ethanol solution was used for desorption, and the elution was collected. Material A; 20 kg of filter residues were dissolved with 40 L of acetone, filter...

Embodiment 3

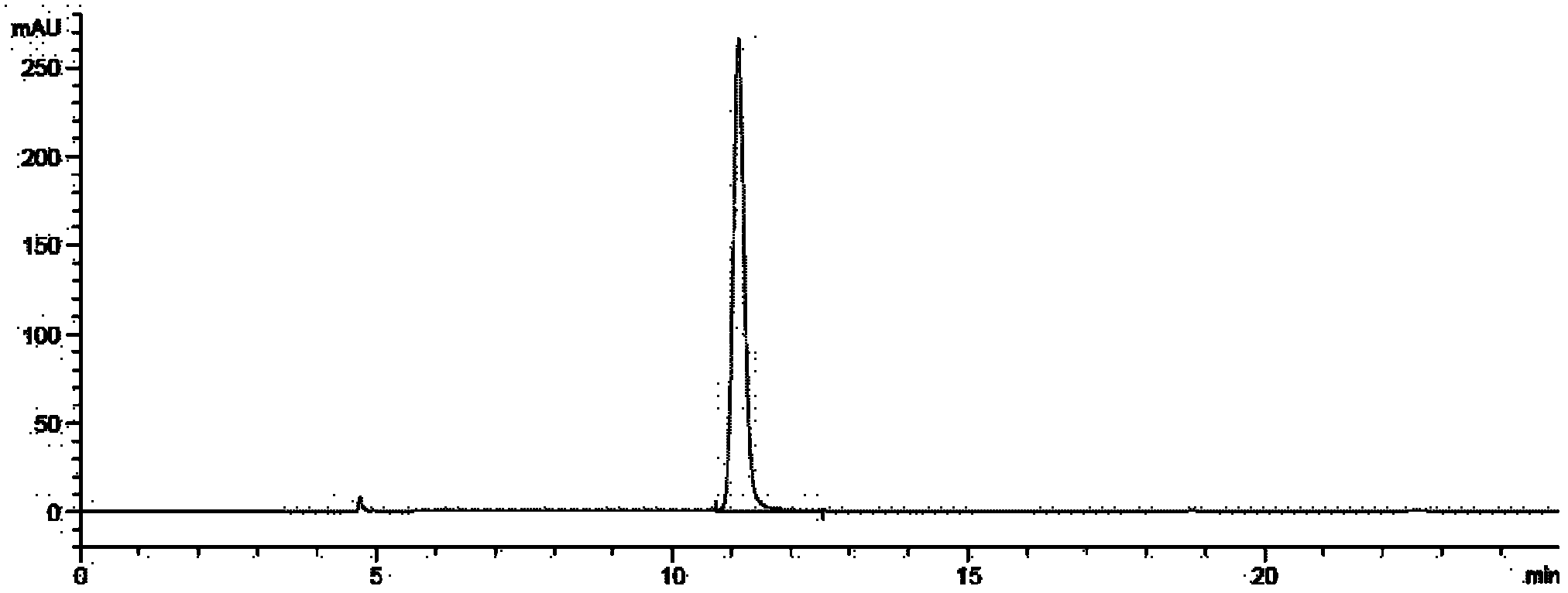

[0052]Weigh 500Kg of rosemary, pulverize it, place it in 1500L (V / V) in 60% ethanol for 4 hours under vacuum at 40°C, filter and filter it once with a ceramic membrane; add the filter residue to 1000L of 60% ethanol, keep it under vacuum at 40°C for 4h, The ceramic membrane was filtered once again, and the two filtrates were combined; the filtrate was added with an appropriate amount of antioxidant 500g and concentrated in vacuo at 50°C until 70kg of dry matter was obtained; the obtained dry matter was dissolved with 350L of 30% ethanol, and activated carbon was added for decolorization for 15min. The ceramic membrane was filtered once, and the filtrate was applied to LSA-10 macroporous resin column. After adsorption, 300L of petroleum ether and 300L of ethyl acetate were used to remove impurities, and 300L of pH3.5, 45% ethanol solution was used for desorption. Removal A; 45kg of filter residue was dissolved with 90L of acetone, filtered, and the filtrate was placed on LSA-10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com