Fly ash concrete small hollow block and preparation method thereof

The technology of fly ash and fly ash cement is applied in the fields of fly ash concrete small hollow brick laying and its preparation, frame structure and high-rise building block filling wall field, and can solve the problem of declining economic benefits, low ash mixing rate, The problem of low ash content, etc., can achieve the effect of improving construction efficiency, simple process and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

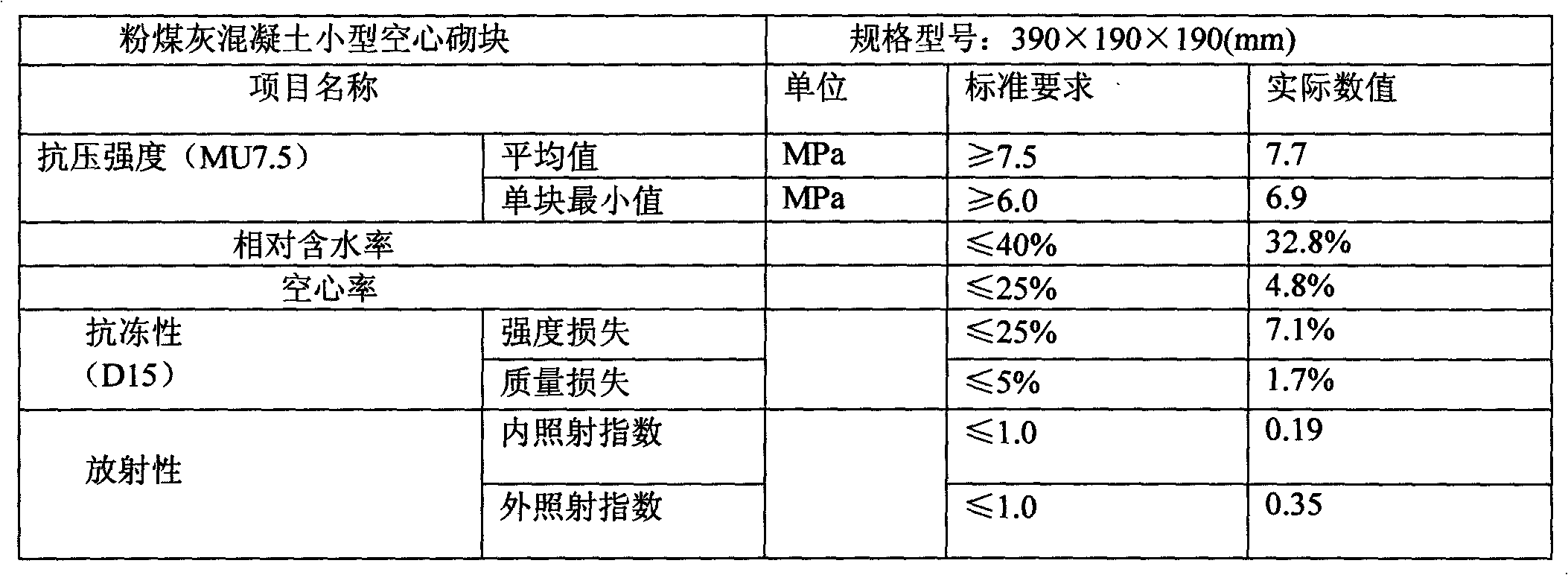

Image

Examples

Embodiment Construction

[0033] The technical scheme of the present invention is: a kind of fly ash cement small hollow brick, the raw material component of described small hollow brick, by weight percentage is respectively

[0034] Dry fly ash: 10--11 parts

[0035] Cement: 35.5-36.5 parts

[0036] Wet fly ash: 185--186 parts

[0037] The preparation of fly ash cement small-sized hollow bricks comprises the following steps;

[0038] a Raw material preparation: use the microcomputer automatic batching metering system to mix the dry fly ash, cement, wet fly ash and water according to the weight percentage:

[0039] Dry fly ash 10--11 parts,

[0040] Cement 35.5--36.5 parts,

[0041] Wet fly ash 185--186 ingredients,

[0042] Water: 23.5-24.5 parts

[0043] Among them, the quality of dry fly ash is Class II ash, and the humidity (referring to moisture content) of wet fly ash in the storage field should generally be 3% to 5%;

[0044] The fly ash used for block products is the dry and wet fly ash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com