Automated production system for metal locking armor and method thereof

A production system and technology of lock armor, applied in the field of metal lock armor production system, can solve the problems of inability to precisely control the production process, inability to adjust the size in time, and unsatisfactory product quality, and achieve the ideal use effect, save labor costs, and operate stably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

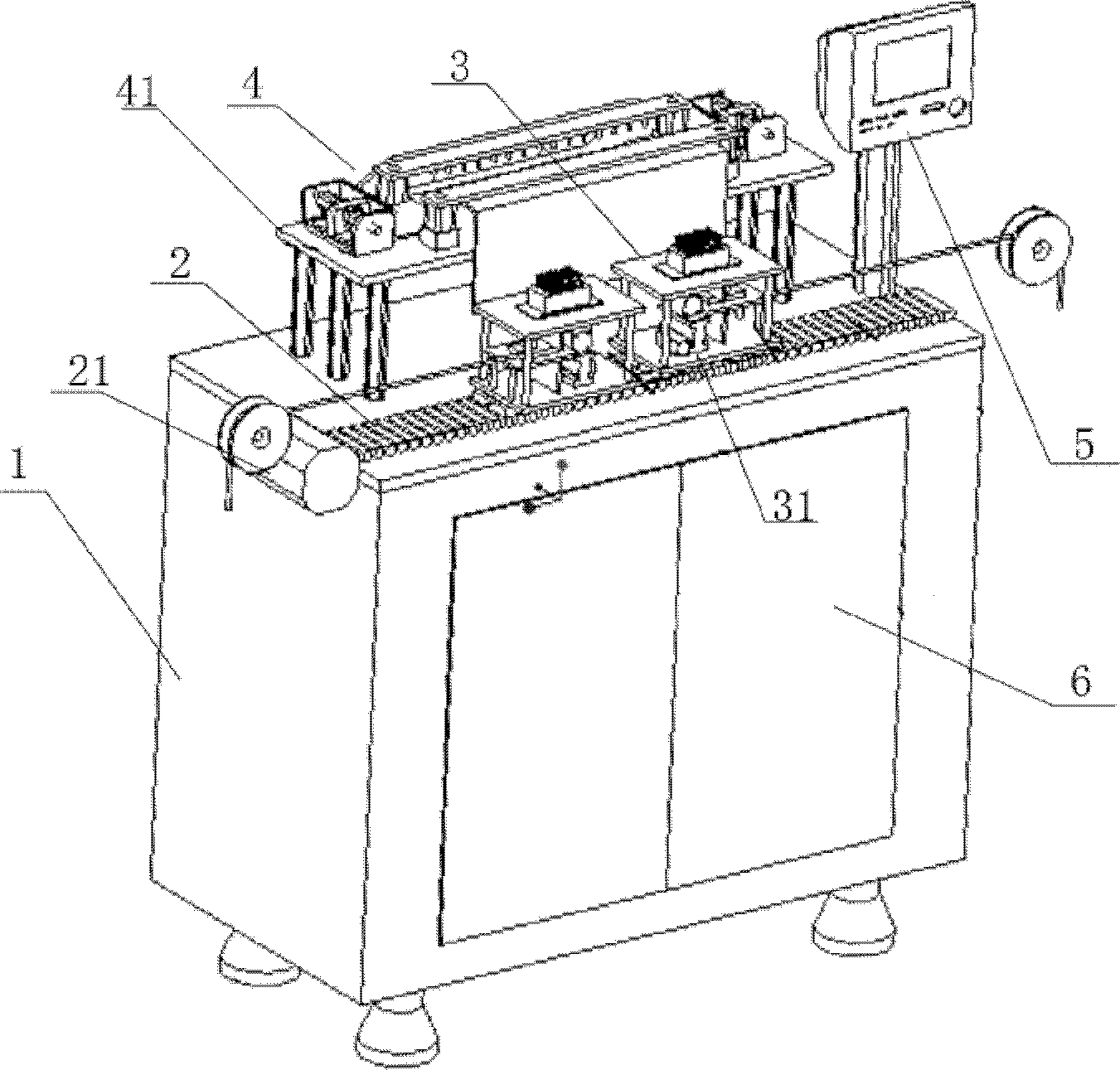

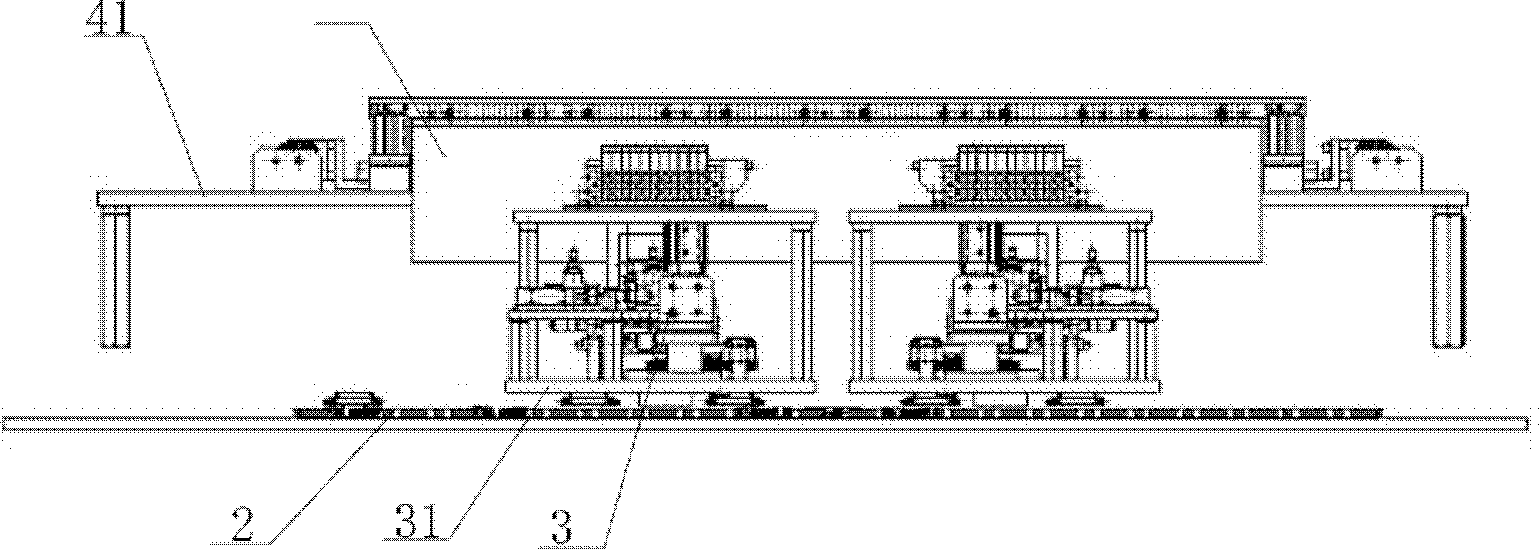

[0064] Example: Automatic production system for metal lock armor, as attached figure 1 with figure 2 As shown, the system is used to weld steel wire rings to the lock armor row by row, where the lock armor refers to the cloth-shaped lock armor in processing, the same below; the system includes;

[0065] An electrical control cabinet 1;

[0066] The linear track 2 is set above the electrical control cabinet 1. The linear track 2 is driven by a stepping motor 21 fixed on the electrical control cabinet 1, and moves back and forth within the stroke at a certain pulse frequency;

[0067] Two ring forming and welding mechanisms 3 are arranged above the linear track 2 and move back and forth within the stroke with the linear track 2 at a certain frequency. The ring forming and welding mechanism 3 is used to cut and shape the steel wire into a ring, and weld the ring to the lock armor;

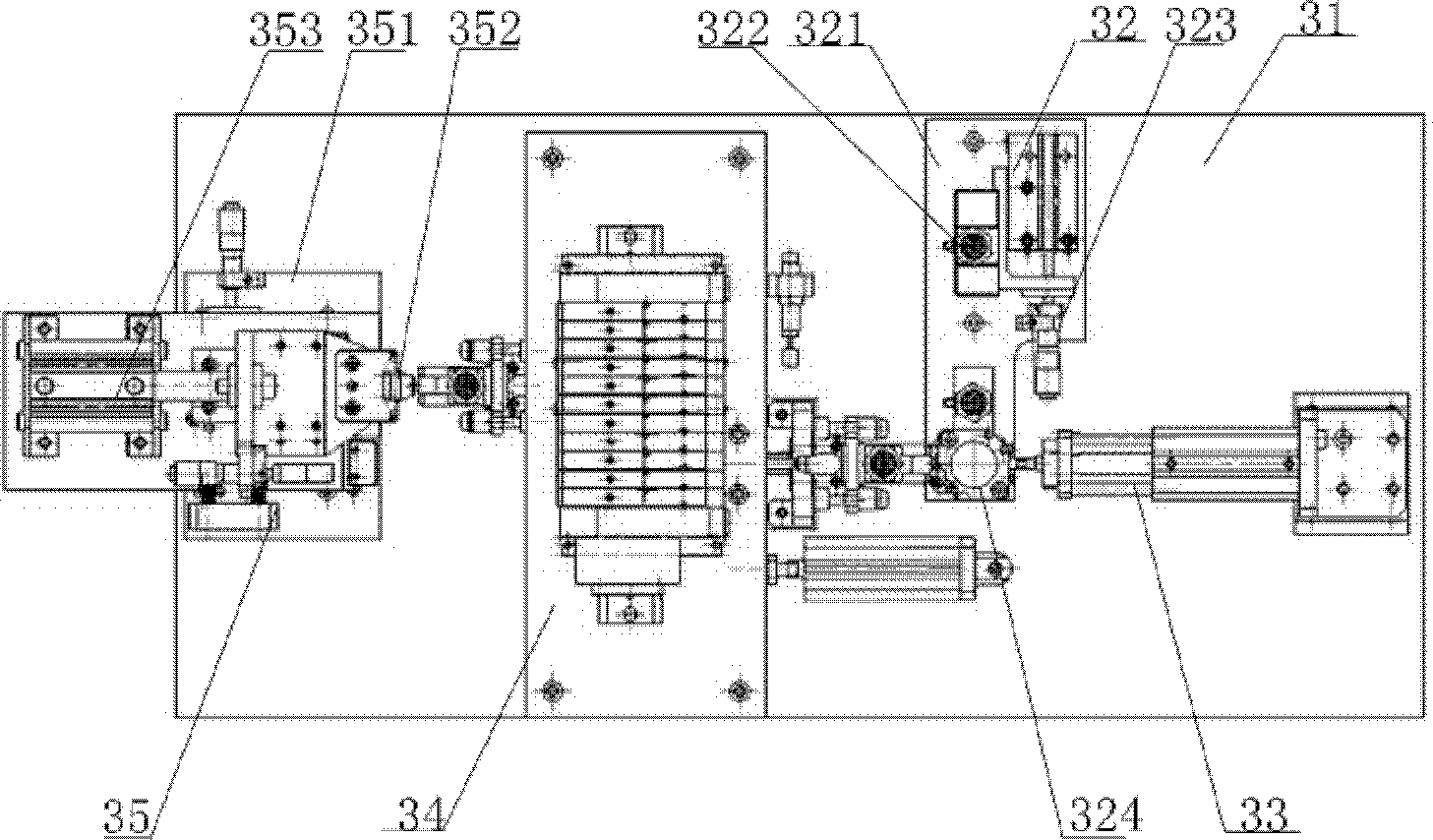

[0068] As attached image 3 As shown, the ring forming and welding mechanism 3 includes a base 31, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com