Integrated system on ultrasonic transducer sheet with MEMS (Micro-Electromechanical Systems) glass sphere and preparation method thereof

An on-chip integrated system and ultrasonic transducer technology, applied in the field of microfluidics, can solve the problems of difficult to achieve on-chip integration and low efficiency, and achieve the effect of high molding height, simple method and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

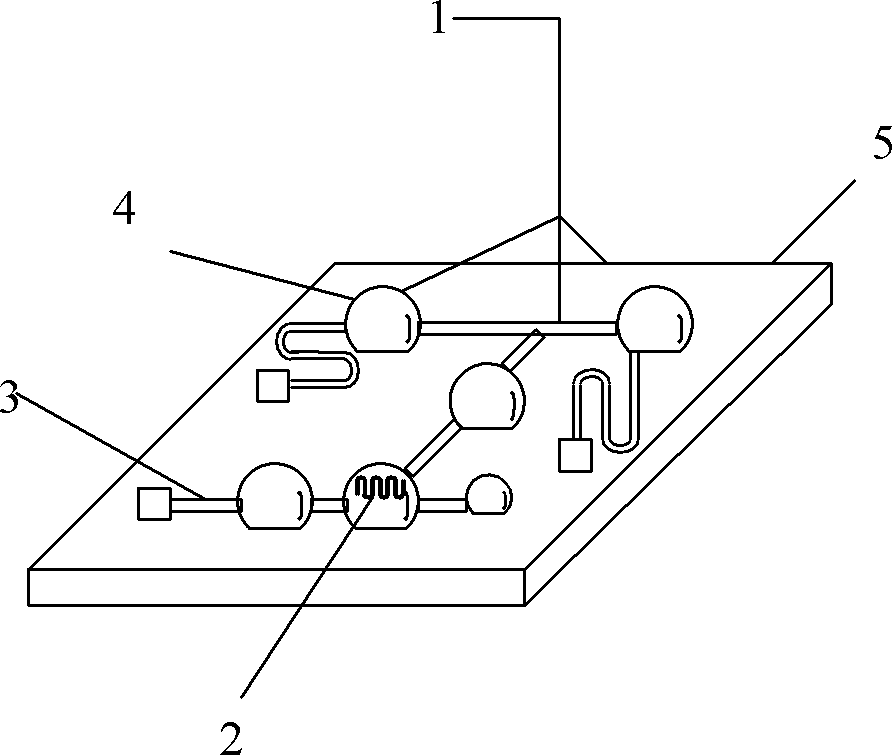

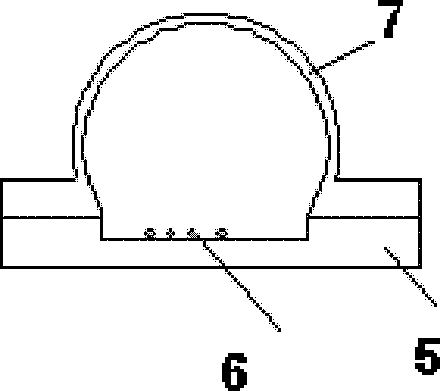

[0026] A method for preparing a microfluidic grid on-chip experimental system integrating a spherical glass cavity focused ultrasonic transmitter, comprising the following steps:

[0027] In the first step, a 5000A oxide layer is oxidized on a single-sided polished silicon wafer by a combination of dry and wet oxygen, and the polished surface is spin-coated with AZ P4620 photoresist, exposed and developed to remove the photoresist that needs to be etched on the surface of the microcavity. Utilize Si micromachining process to etch the microcavity and microchannel shallow cavity on the 4-inch Si wafer, and the microchannel connects the shallow cavity. The depth of the cavity is 60-100 microns, the micro-cavity is a square or circular cavity with a width of 1000-5000 microns, the micro-channel cavity is a strip-shaped cavity with a diameter of 50 microns, and the length of the cavity is 5 mm. Cavity square cavity, the micromachining process of the pattern structure on the Si wafe...

Embodiment 2

[0035] A method for preparing a microfluidic grid on-chip experimental system integrating a spherical glass cavity focused ultrasonic transmitter, comprising the following steps:

[0036] In the first step, a 5000A oxide layer is oxidized on a single-sided polished silicon wafer by a combination of dry and wet oxygen, and the polished surface is spin-coated with AZ P4620 photoresist, exposed and developed to remove the photoresist that needs to be etched on the surface of the microcavity. Utilize Si micromachining process to etch the microcavity and microchannel shallow cavity on the 4-inch Si wafer, and the microchannel connects the shallow cavity. The depth of the cavity is 60-100 microns, the micro-cavity is a square or circular cavity with a width of 1000-5000 microns, the micro-channel cavity is a strip-shaped cavity with a diameter of 50 microns, and the length of the cavity is 5 mm. Cavity square cavity, the micromachining process of the pattern structure on the Si wafe...

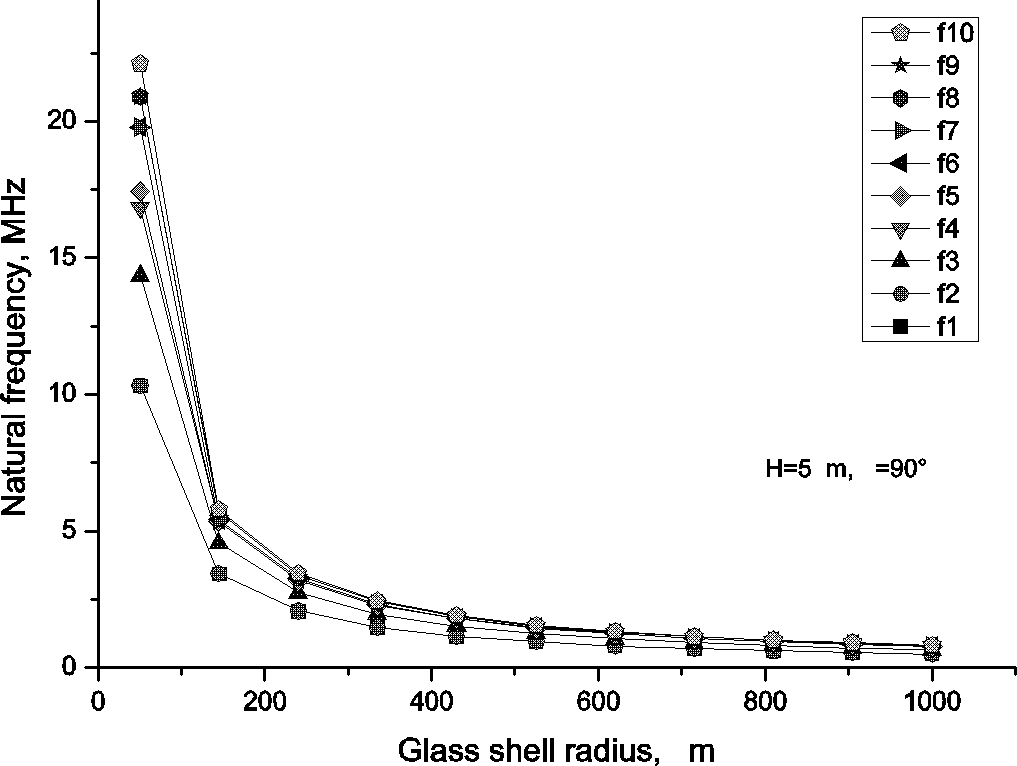

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com