Kinematic mirror mount adjustable from two directions

A technology for kinematic, reflector applications in the field of positional devices that can address issues affecting mirror mount size, weight, and other physical properties, violations of overall profile and mechanical packaging, and proximity adjustment actuator limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

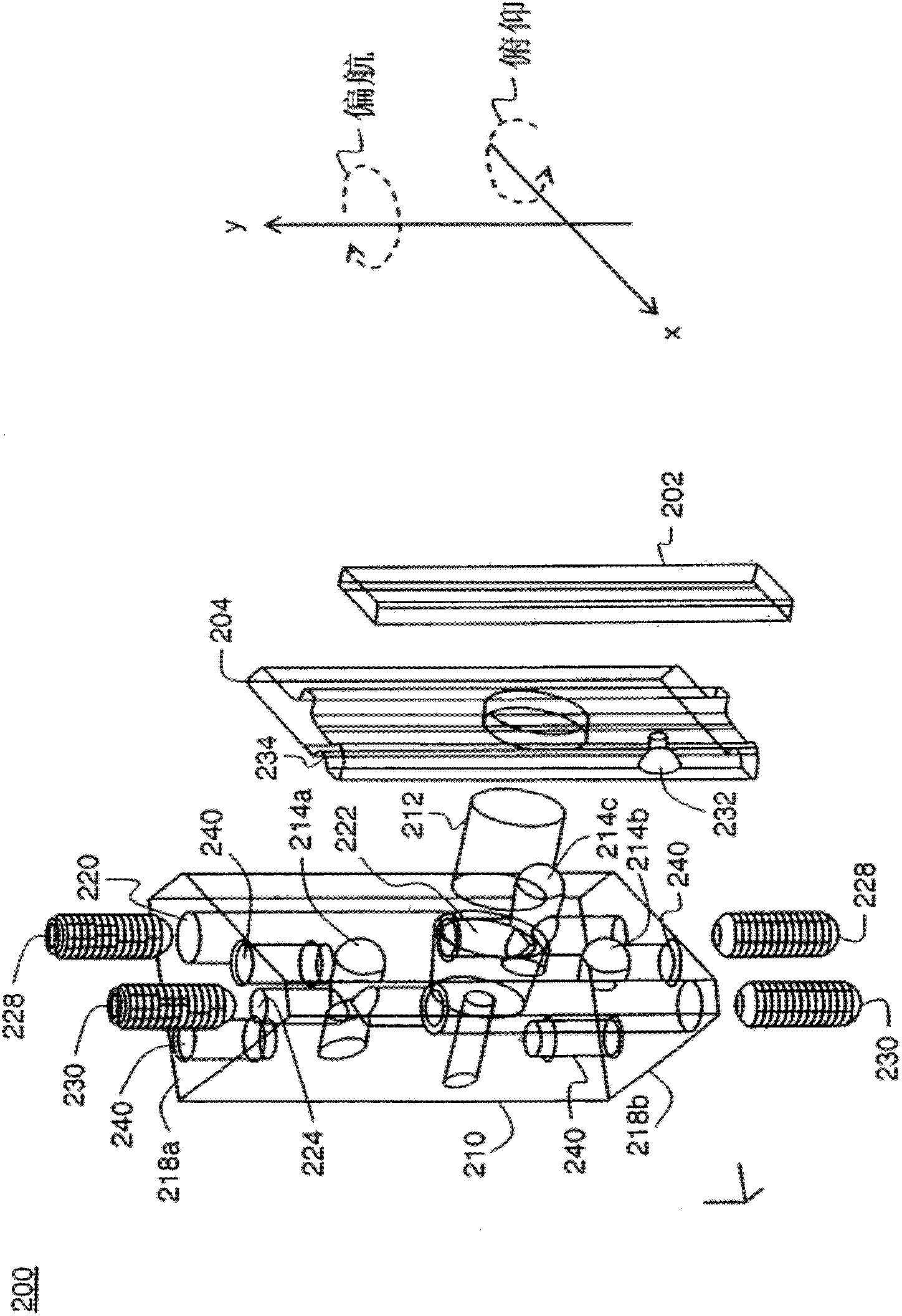

Image

Examples

Embodiment Construction

[0026] The description focuses in particular on elements forming part of, or cooperating more directly with, the device according to the invention. It is to be understood that elements not specifically shown or described may take various forms well known to those skilled in the art.

[0027] The drawings shown and described herein are for illustrating principles of operation according to the present invention and may not be drawn to show actual size or scale. Due to the relative dimensions of the constituent parts of the mirror mount of the present invention, some exaggeration is necessary in order to emphasize the basic structure, shape and principles of operation.

[0028] The terms "bottom" and "top" are used to refer to opposing surfaces or other features of components described and shown herein, but are not used to limit the components to a vertical orientation. One advantage of the mirror mount of the present invention relates to its adaptability of orientation in direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com