Support cone for silicon seed bars

A technology of growing rods and cones, applied in the field of accommodating cones, to achieve the effect of reducing heat demand, reducing heat dissipation, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

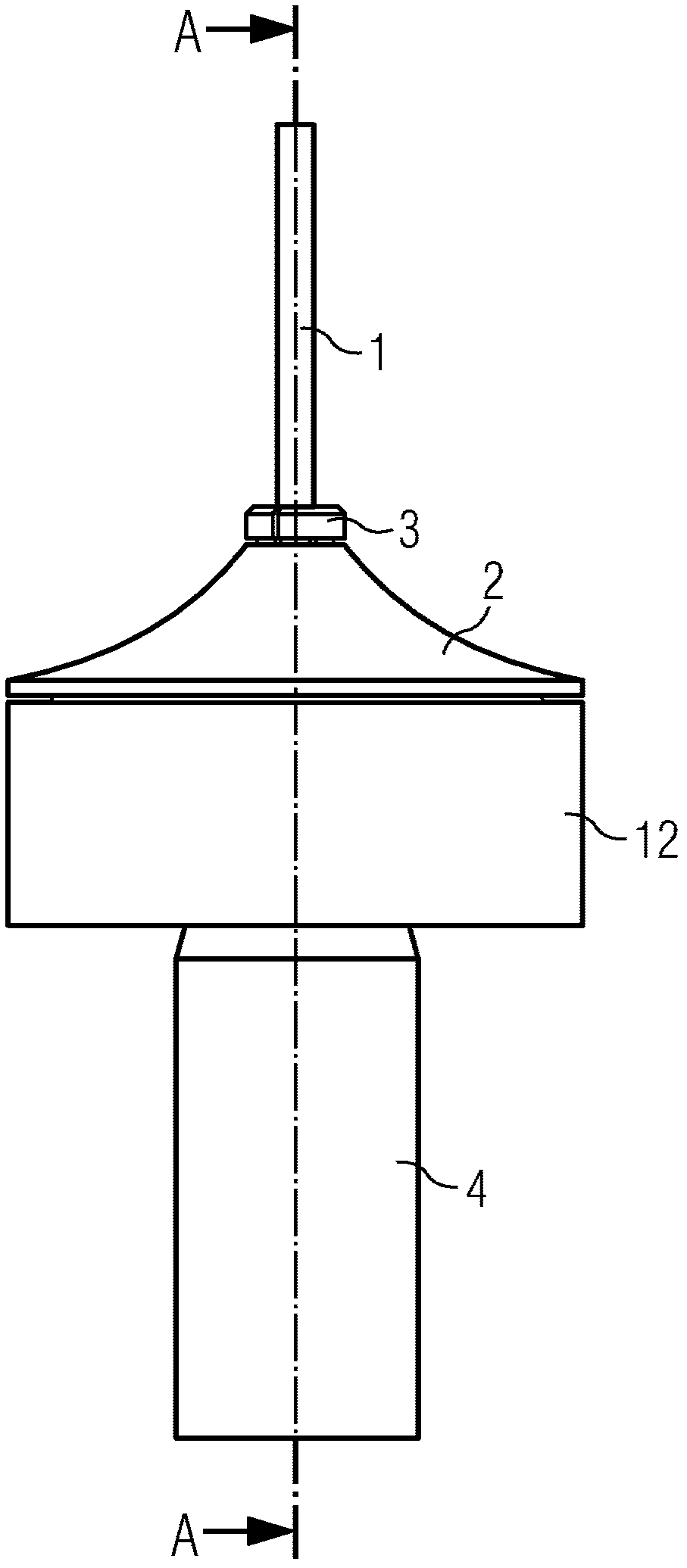

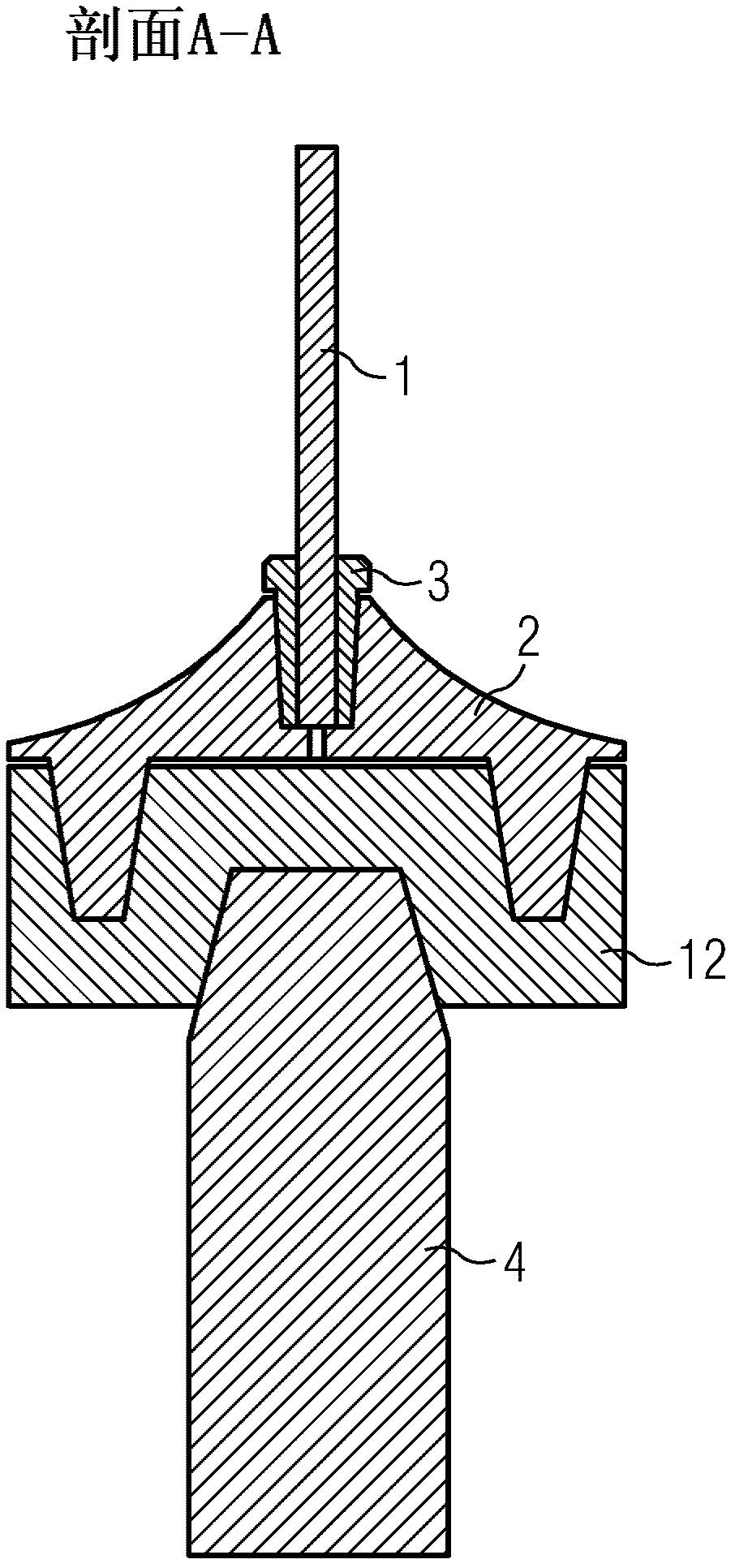

[0049] The receiving cone according to the invention for silicon growth rods 1 consists of a rotationally symmetrical base body 2 with a one-piece, centrally inserted uppermost position into the base body 2 for receiving silicon growth rods. Stick 1 ( figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 ) clamping element 3. The base body 2 is provided with pot lid-like recesses ( Figure 6 ). The edge 5 of the base body 2 can simultaneously be inserted into a current feed in the bottom of the reactor, not shown, wherein the individual components: silicon growth rod 1, clamping element 3, base body 2 and holder for the current feed And the coupling pins 4 can be interleavedly plugged into each other in a form-locking and force-locking manner.

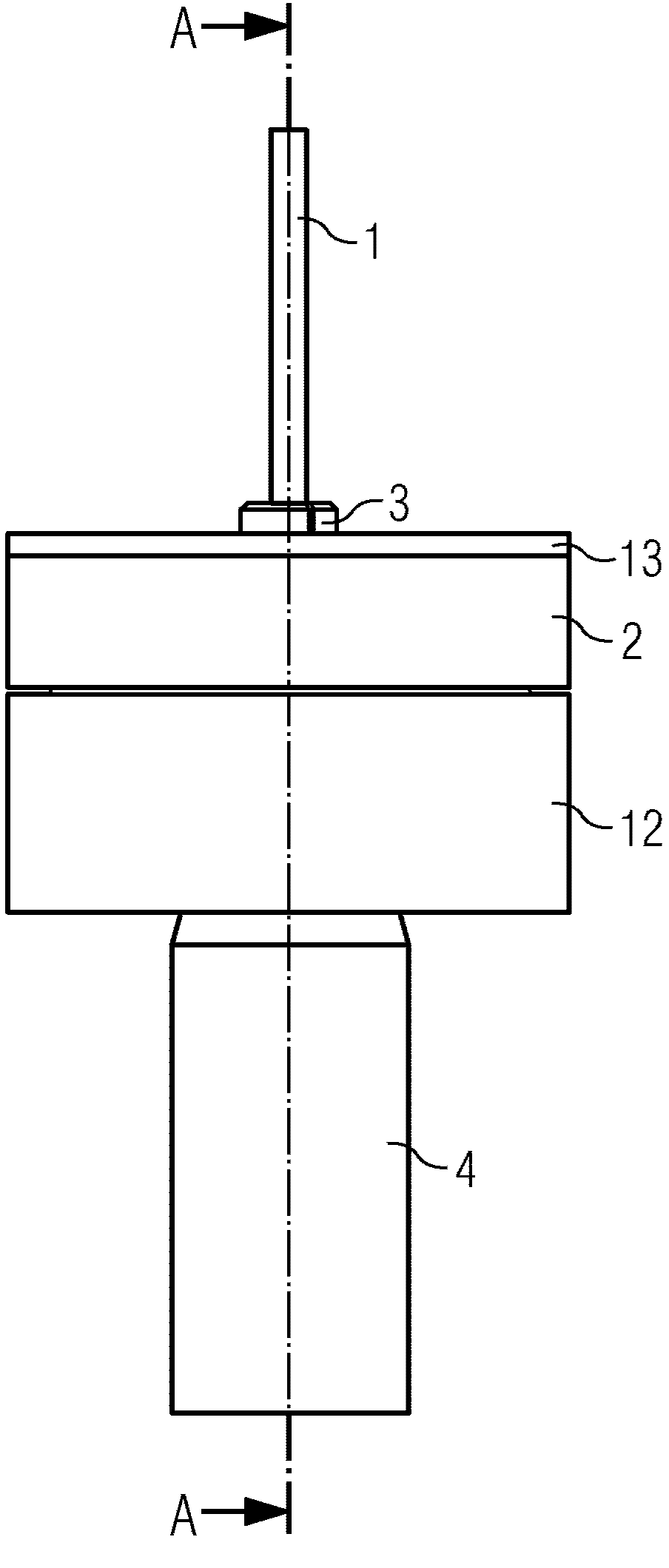

[0050] image 3 , Figure 4 as well as Figure 8 , Figure 9 , Figure 10 A variant of the receiving cone is shown, in which the base body 2 does not extend conically upwards to the end, but is formed flat.

[0051] To ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com