Induction preheating process for cast iron liners of aluminum cylinder bodies of four-cylinder engine

An induction preheating, engine technology, applied in induction heating, induction heating devices and other directions, can solve the problems of difficult to ensure temperature uniformity, difficult automatic casting production, low production efficiency, etc., to achieve high popularization and application value, high production efficiency, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

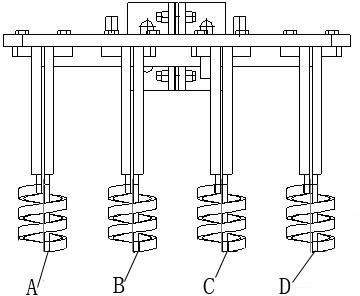

[0014] Such as figure 1 As shown, the four-cylinder engine aluminum cylinder block cast iron cylinder liner preheats the sensor at the same time. Plate 7 and solenoid type effective ring 8; the middle of the contact plate is connected with an insulating plate, and both sides of the contact plate are connected with a cooling water inlet pipe and a cooling water outlet pipe; it is characterized in that: the solenoid type effective ring 8 is four One, the upper part is fixed by the fixed plate 7, the effective circle has three turns of winding and the spiral direction is the same, two strings and two parallel connections, in which the effective circle A and the effective circle B are connected through a series transition wire 1, and the effective circle C and the effective circle D are connected through a series connection The transition wires 1 are connected, and then the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com