Helical blade rotary spray gun for desulfurization of molten iron

The technology of molten iron desulfurization and rotary spray gun is applied in the field of desulfurization devices in the metallurgical casting industry, which can solve the problems of low desulfurization efficiency, poor mixing effect of desulfurization agent and molten iron, and high splash strength of desulfurization agent, and achieves high desulfurization efficiency, simple structure, The effect of long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

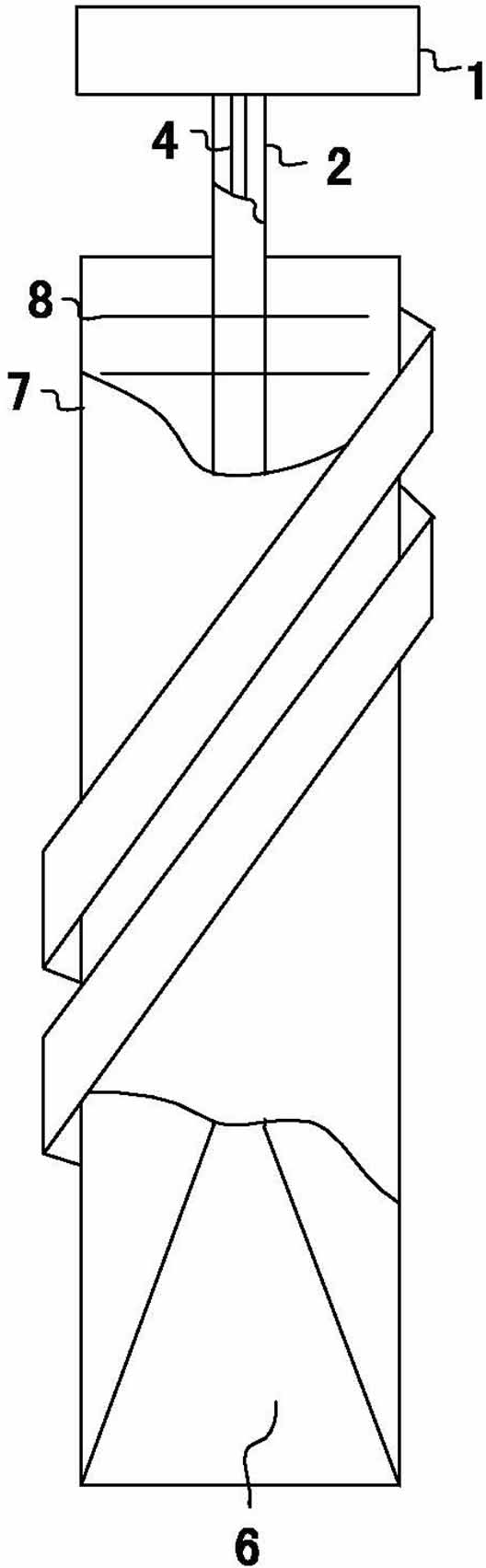

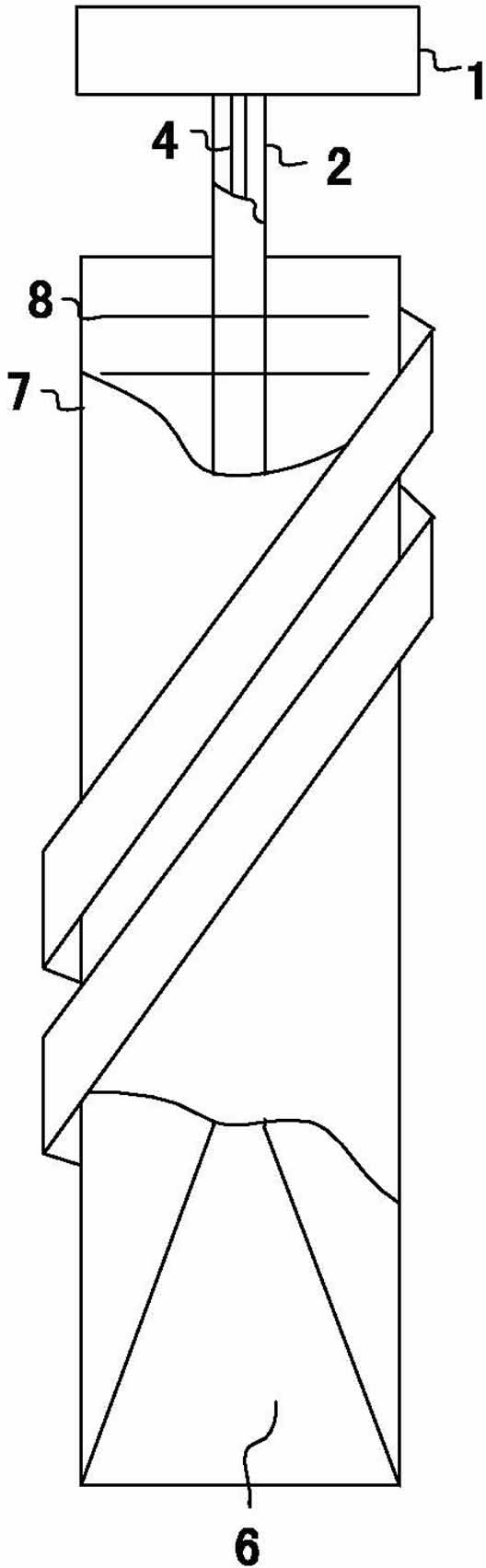

[0015] As shown in the figure, the spiral blade molten iron desulfurization rotary spray gun includes a flange connector 1, a stirring shaft 2 fixedly connected to the flange connector 1, and a stirring blade 3 fixedly connected to the lower part of the stirring shaft 2; The agitating shaft 2 is fixed with a nozzle 4; the agitating blade 3 and the agitating shaft 2 are provided with a refractory material layer 7; the agitating blade 3 adopts a spiral structure.

[0016] The included angle between the stirring blade 3 and the stirring shaft 2 in the present invention is 20°≤a≤30°.

[0017] In order to improve the stress distribution in the gun body and avoid cracking and falling off of the refractory material, the refractory material layer 7 of the present invention is provided with an annular stress adjustment rib 8 .

[0018] In the present invention, a vaporization chamber 6 is fixedly arranged at the bottom of the nozzle 4 .

[0019] When the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com