Train pipe low-pressure protection system and method applicable to locomotive braking system

A low-voltage protection and braking system technology, applied in the direction of pneumatic brakes, hydrostatic brakes, hydrodynamic brakes, etc., can solve the problem of large fluctuations in brake cylinder pre-control pressure, attenuation of locomotive braking force, and large total wind consumption, etc. problems, to achieve the effect of solving the leakage problem of the safety valve, realizing low pressure protection, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

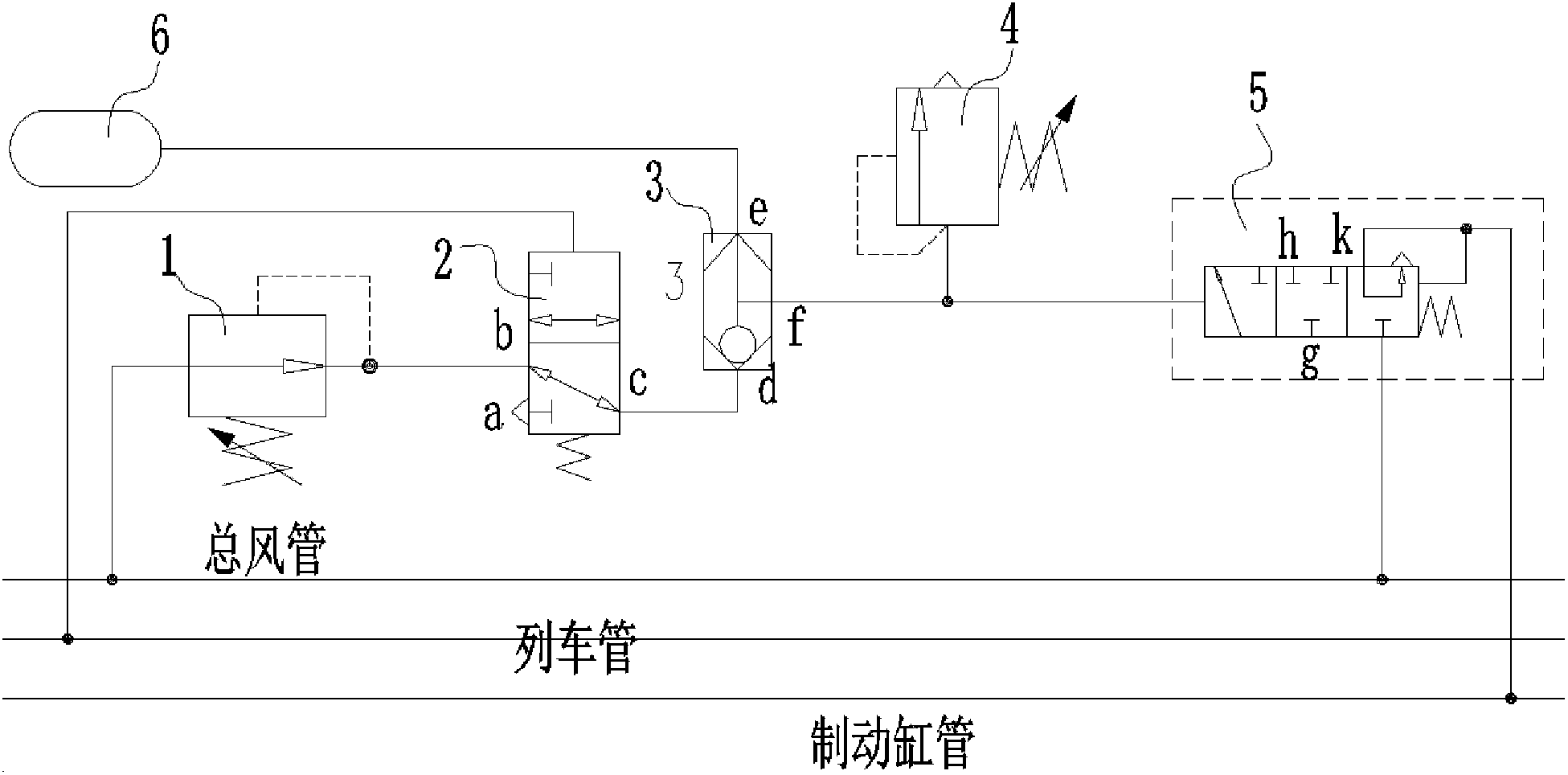

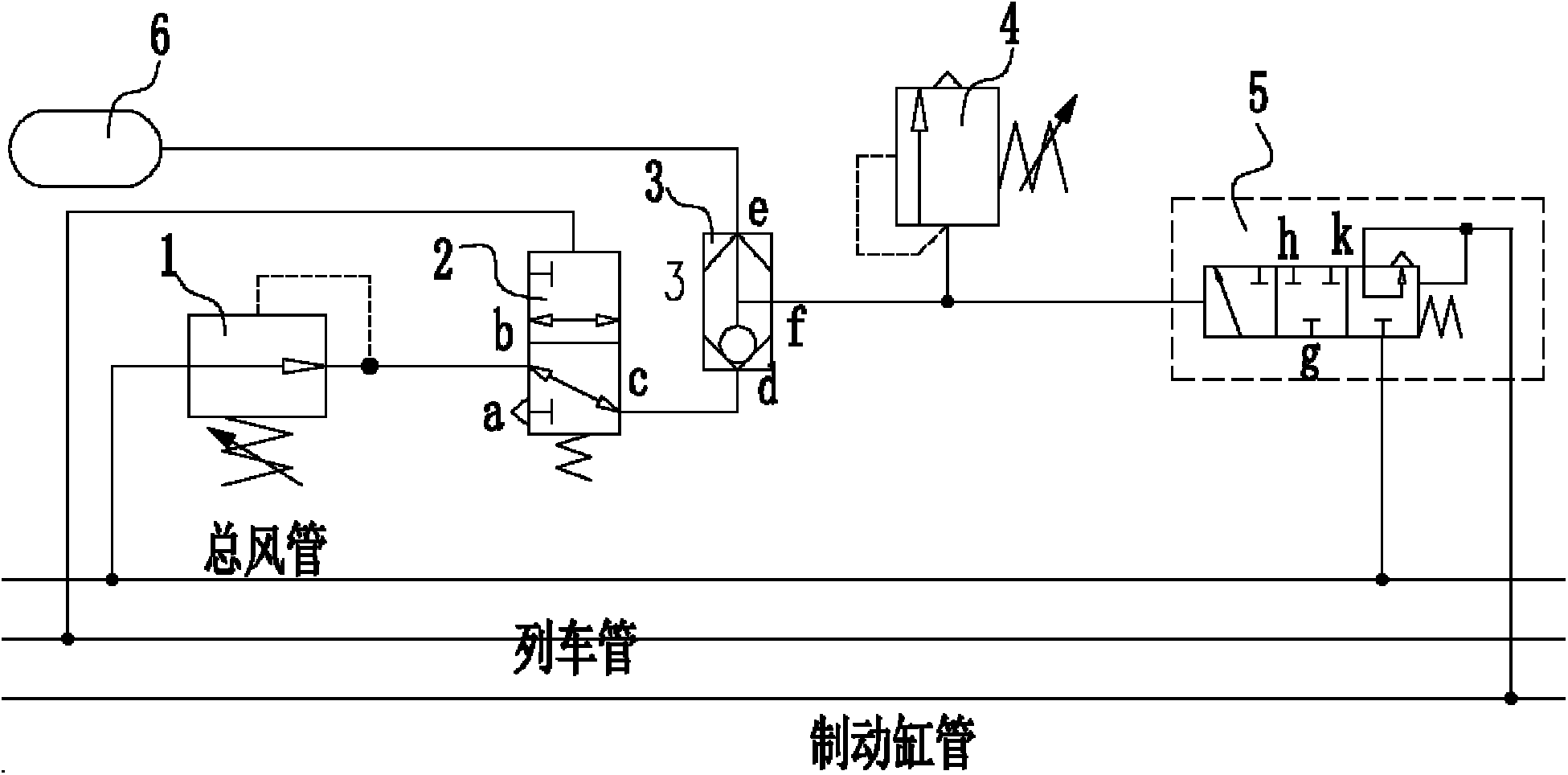

[0026] A train pipe low pressure protection system adapted to the locomotive braking system, such as figure 2 As shown, it includes pressure regulating valve 1, two-position three-way pneumatic valve 2, or gate type shuttle valve 3, no-fire return safety valve 4, action valve 5, volume chamber 6, and its pressure is only the same as the usual decompression amount of the train pipe relevant.

[0027] Such as figure 1 As shown, when the train pipe is initially filled with air, the air pressure of the train pipe starts to rise from 0kPa at this time. When the pressure value of the train pipe is lower than the spring adjustment value of the two-position three-way pneumatic valve 2, the total air is adjusted by the safety valve 1. Finally, through the valve port b and valve port c of the two-position three-way pneumatic valve 2, or the valve port d and valve port f of the door-type shuttle valve 3, it reaches the control end of the acting valve 5 to form the control pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com