In-Situ Preparation of Novel Iron/Carbon Nanotube Hierarchical Nanocomposites

A technology of nanocomposite materials and carbon nanotubes, applied in the field of nanocomposites, can solve the problems of long cycle, complicated steps, and application limitations, and achieve the effects of low cost, simple process, and unique formation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

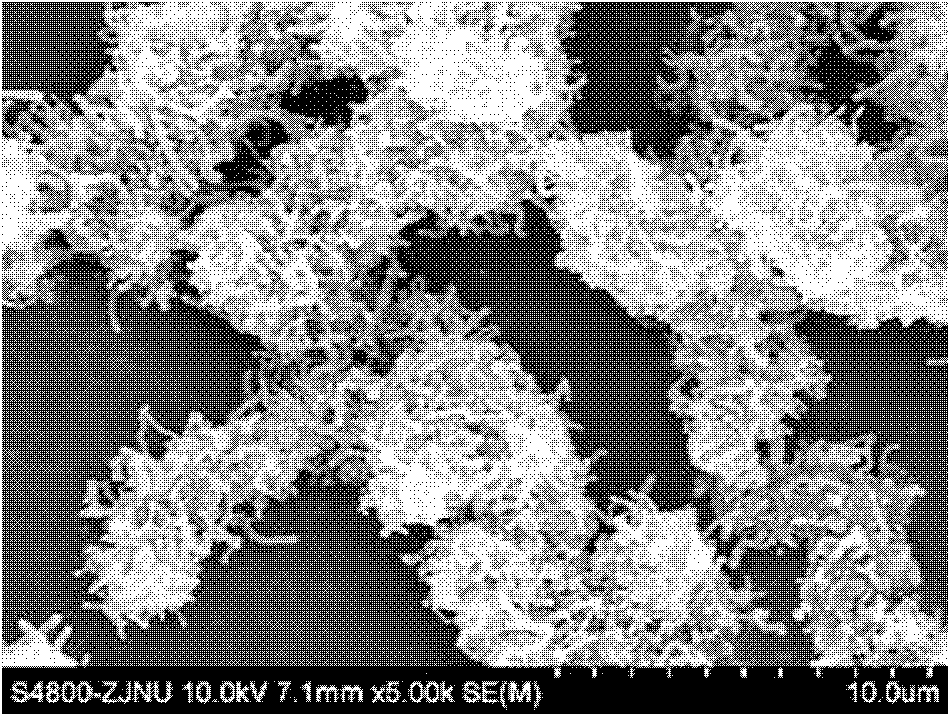

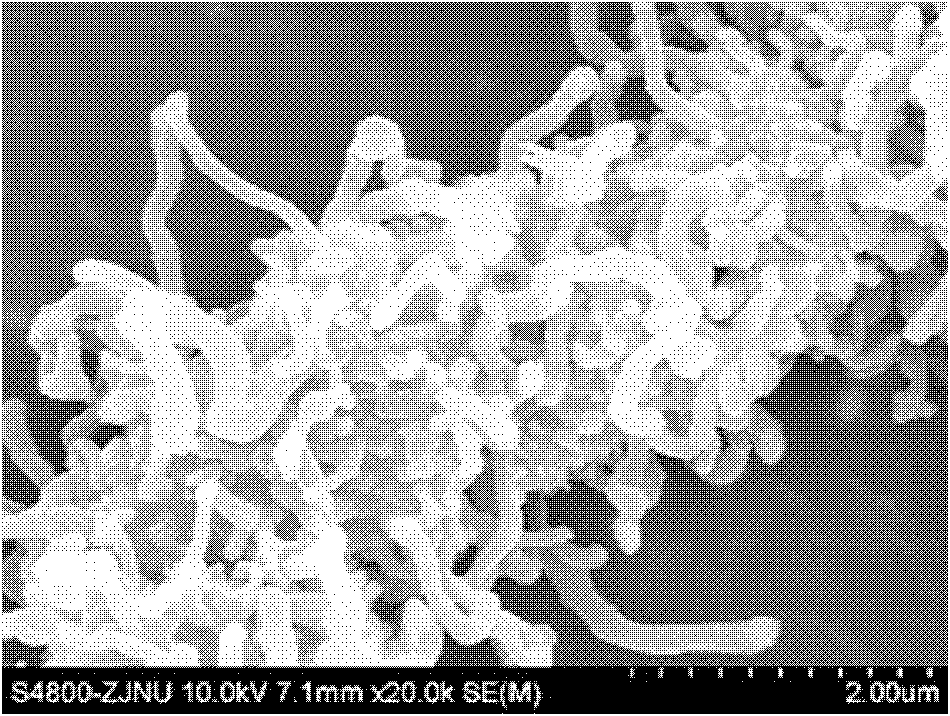

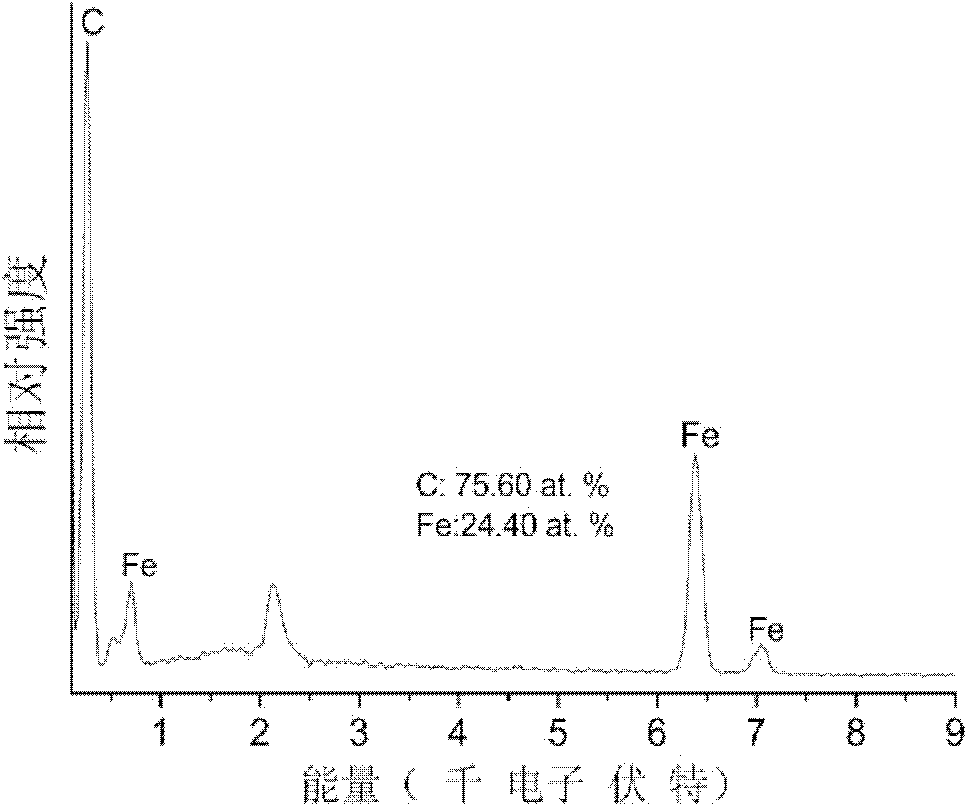

[0041] Load 1 milliliter of iron pentacarbonyl and 2 grams of polyethylene glycol 20000 in ceramic arks of 8 cm × 1.2 cm × 1 cm respectively, place them in a tube furnace (inner diameter × tube length = Φ2 cm × 60 cm), and raise the temperature under nitrogen protection After heat preservation at 300°C for 30 minutes, continue to raise the temperature to 700°C and heat preservation for 2 hours. After the reaction was completed, it was cooled to room temperature with the furnace under the protection of nitrogen, and the morphology of the resulting product was as follows: figure 1 with figure 2 Shown is a new iron / carbon nanotube hierarchical nanocomposite. image 3 The EDS spectrum of the product shows that the mass percentages of carbon and iron are 75.60% and 24.40%, respectively. The TEM image of the product was observed under the transmission electron microscope Figure 4 , it can be seen that the carbon on the surface of the hierarchical structure exists in the form of...

Embodiment 2

[0043] The process in Example 1 was adopted, except that when the iron pentacarbonyl was 2 ml and the shielding gas was a mixed gas of nitrogen and argon (volume ratio=1:1). The morphology of the obtained product is as Figure 5 with Image 6 Shown is a new iron / carbon nanotube hierarchical nanocomposite. Figure 7 The EDS spectrum of the product shows that the mass percentages of carbon and iron are 66.17% and 33.83%, respectively. This indicates that adjusting the mass ratio of organic matter to iron source can not only change the morphology of the product, but also regulate the composition of the product.

Embodiment 3

[0045] Adopt the technique in embodiment 2, difference is: when polyethylene glycol 20000 is 0.5 gram. from Figure 8 The EDS spectrum of the elemental composition analysis shows that the mass percentages of carbon and iron are 10.88% and 89.12% respectively. The morphology of the obtained product is as Figure 9 with Figure 10 shown. Because the relative content of organic matter is small, the carbon source is low and the carbon tubes grown on the surface are short. This indicates that adjusting the relative content of carbon source can also adjust the morphology of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com