Method for preparing high-brightness flowing luminescence electric wire

A luminous wire, high-brightness technology, applied in the field of electroluminescent devices, can solve the problems of data wire frequency signal interference, limit the use of luminous wires, and thick wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

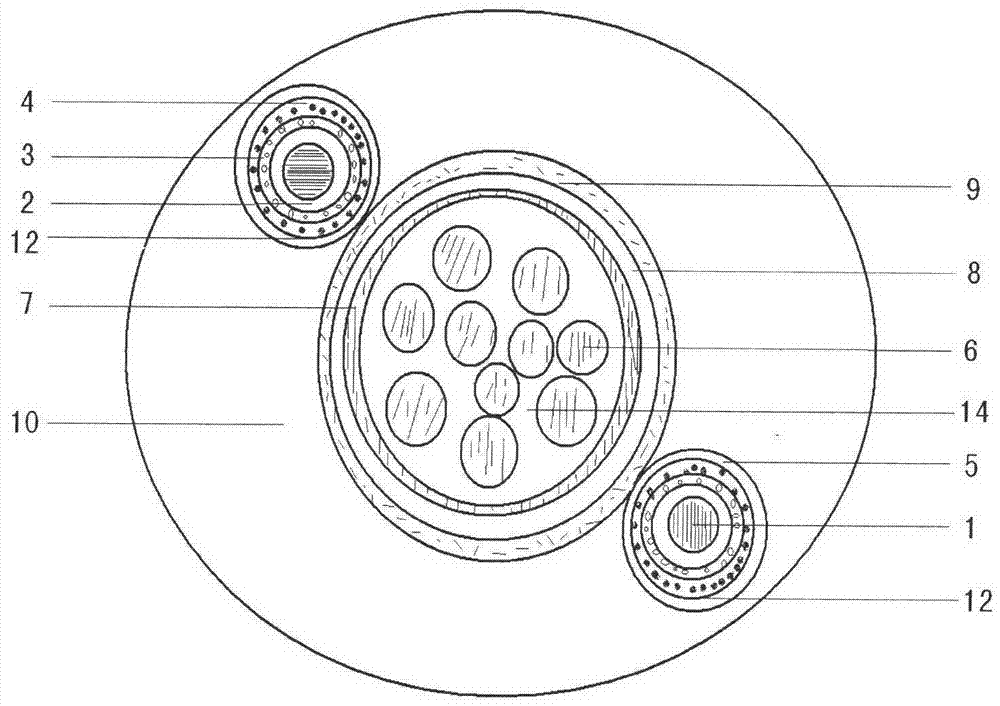

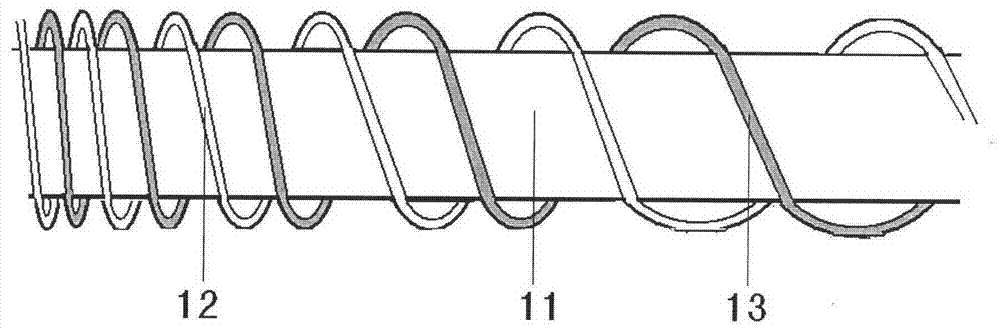

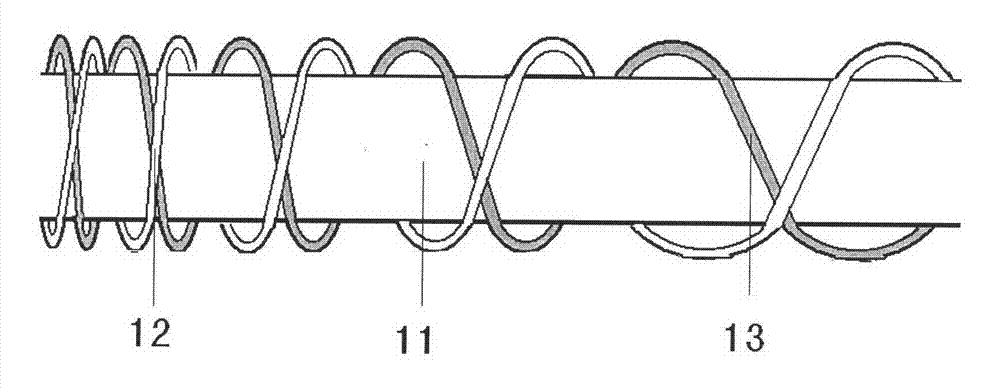

[0028] A preparation of a high-brightness flowing luminous wire, which includes: a central data line 11, a plurality of luminous lines 12, and an outer transparent plastic protective layer 10; a plurality of luminous lines are wound in parallel or crossed on the outside of the central data line, and the luminous lines It can be regularly combed and combined during winding, and better results can be produced during dynamic changes; and it is completely wrapped by the outer transparent plastic protective layer 10. The transparent plastic protective layer uses materials such as PVC, PE, PU, etc., which can be It is colorless and transparent, or it can be colored and transparent with fluorescence, so as to prepare colored luminous lines. Adding 0.1-10% fluorescent whitening agent can effectively improve the luminous uniformity and luminous intensity. The inner conductive layer 9 outside the central data line and the metal core 1 of the light-emitting line are respectively connect...

Embodiment

[0038] In the preparation of a high-brightness flowing luminous wire of the present invention, the central data line is made of multi-strand copper metal wire with a diameter of 1 mm, the inner insulating layer is coated with polyurethane, the metal shielding coating is coated with silver paste, and the insulating layer is coated with polyurethane. The inner conductive layer uses a silver paste layer, and the above are prepared one by one by infrared temperature curing.

[0039] Instructions for the use of the metal core of the central luminous line of the present invention is 0.1mm copper wire. The medium layer of the luminous line is made of copper calcium titanate coating film. The most important is the nano-zinc oxide nano-material coating film, and the transparent conductive layer of the luminescent line uses the ATO transparent conductive material coating film. The adhesive applied above uses fluorine-containing paint, which is cured by infrared heating, and the coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com