Semiconductor wet etching device and method

A wet etching, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven corrosion, inability to corrode silicon wafers, film residues, etc., to increase the vertical corrosion rate and increase flow Sexuality, the effect of reducing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

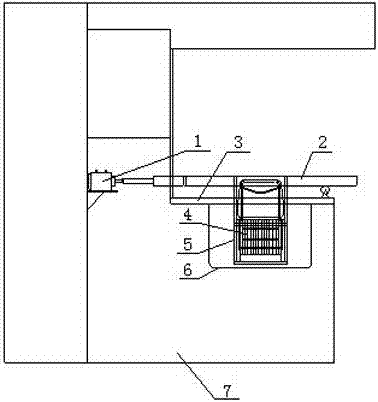

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] A device for semiconductor wet etching, including an equipment support 7, on which a transmission device, a flower basket support 5 and a tank body 6 containing corrosive liquid are arranged, and the transmission device drives the flower basket support 5 to reciprocate in the tank body 6.

[0020] Specifically, the transmission device is composed of a cylinder 1, a guide rail bracket 2 and a guide rail 3. The cylinder 1 is fixedly arranged on the inside of the equipment support 7, and is connected to the guide rail bracket 2 that is arranged on the outside of the equipment support 7 through a transmission shaft. Slidingly arranged on the guide rail 3, the guide rail 3 is arranged on the side edge above the tank body 6; a pulley can be set on the guide rail 3, and the guide rail bracket 2 can slide on the pulley to realize reciprocating motion; the flower basket brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com