Loaded coal rock constant pressure gas adsorption desorption testing system and method thereof

A technology of adsorption and desorption and test system, which is applied in the field of constant pressure gas adsorption and desorption test system and method of loaded coal and rock, can solve the problem of inability to quantitatively analyze and calculate the law of gas adsorption and desorption and gushing law, the inability to quantitatively calculate the amount of gas gushing, Unable to quantitatively analyze and calculate the attenuation law of borehole gas emission and the amount of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

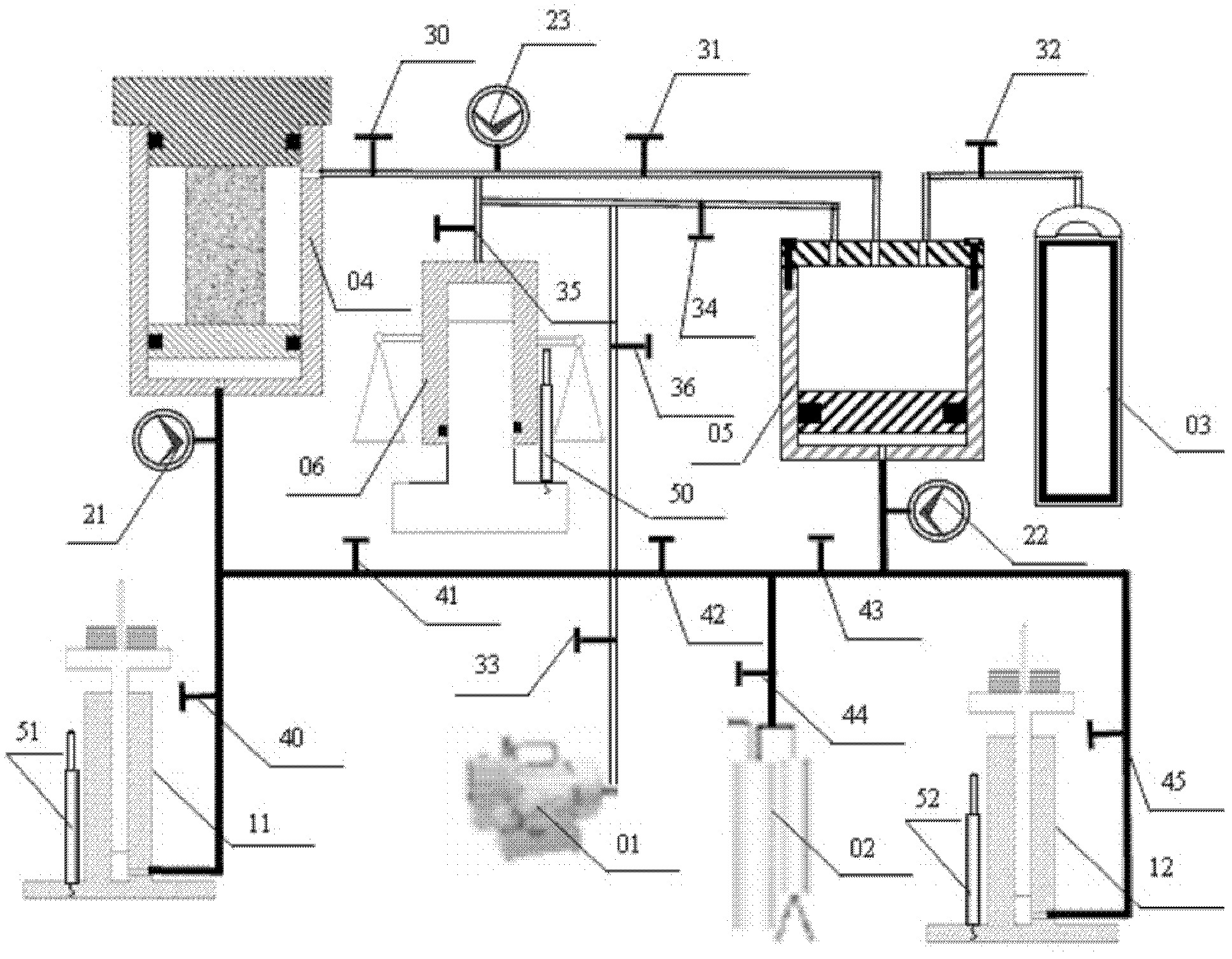

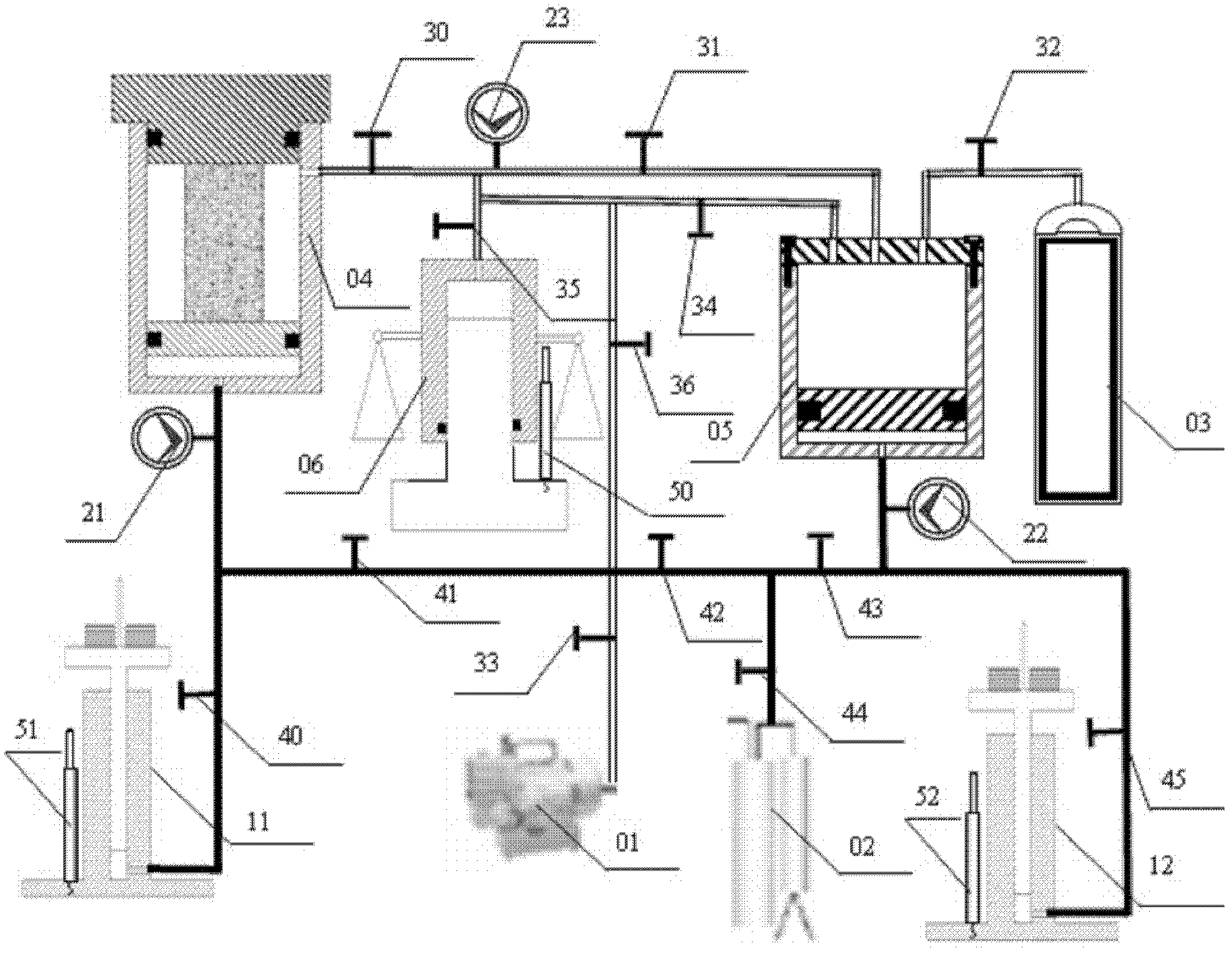

[0041] like figure 1 As shown, including vacuum pump 01, hand pump 02, high pressure gas cylinder 03, sample tank 04, constant pressure gas tank 05, gravity constant air pressure device 06, gravity constant hydraulic pressure device 11 and 12, pressure gauges 21-23, air pressure valve 30-36, hydraulic valve 40-45, displacement gauge 50-52.

[0042] Two gravity and constant hydraulic pressure devices 11 and 12 are respectively used for the constant pressure gas pressure in the constant pressure gas tank 05 and the constant load of the sample in the sample tank 04, mainly used for gas adsorption test research;

[0043] Gravity and constant air pressure device 06 is mainly used for gas desorption test research;

[0044] There is a movable piston in the constant pressure gas tank 05. The piston divides the constant pressure gas tank into two closed variable spaces, which are used to seal the gas and emulsion respectively. There are three outlets in the upper space of the constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com