Fire grate for high-efficiency biomass burning furnace

A biomass combustion furnace and grate technology, which is applied in the direction of combustion method, combustion equipment, grate, etc., can solve the problems of direct drop of biomass fuel and high production and processing costs, achieve low production cost, and prevent ashing and plugging holes , materials achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail.

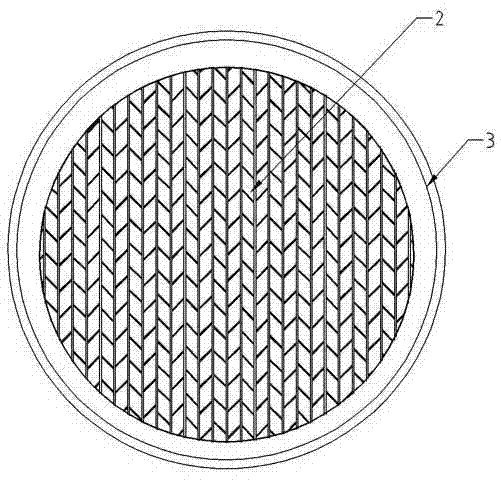

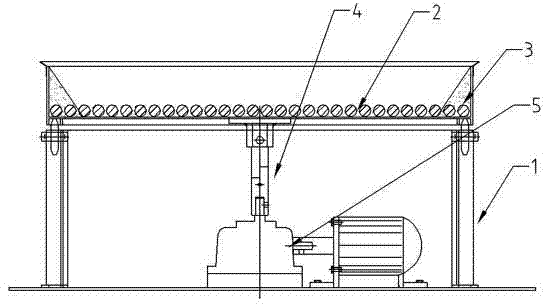

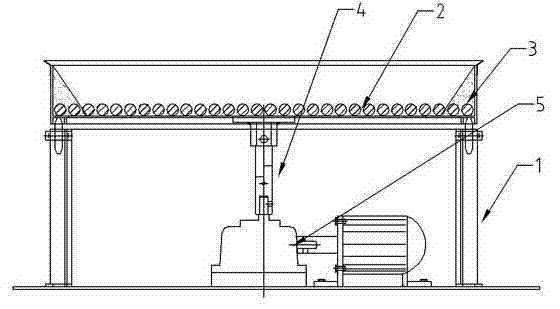

[0014] Reference attached Figure 1-2 , a fire grate for high-efficiency biomass combustion furnaces, mainly composed of a circular fence and a positioning cylinder (1) up and down; its feature is that the grilles (2) forming the circular fence are all made of commercially available threaded Shaped steel bars, several grid bars (2) are arranged together and lapped on a cylindrical frame (3) with an inner inverted cone to form a circular fence, and the grid bars (2) are closely spaced without gaps. contact; the center of the lower part of the circular fence is connected with the reduction transmission mechanism (5) through a rotating shaft (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com