Riser support device under ultra-deep sea water

A support device and riser technology, applied in support devices, drilling equipment, earthwork drilling and production, etc., can solve the problems of increasing the construction and operation costs of floating production devices on the water surface, the applicability and economy of TTR risers, and increasing the water surface Problems such as the dynamic load of the floating production device can achieve the effect of simplifying the installation and dismantling process, reducing the construction cost and simplifying the difficulty of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

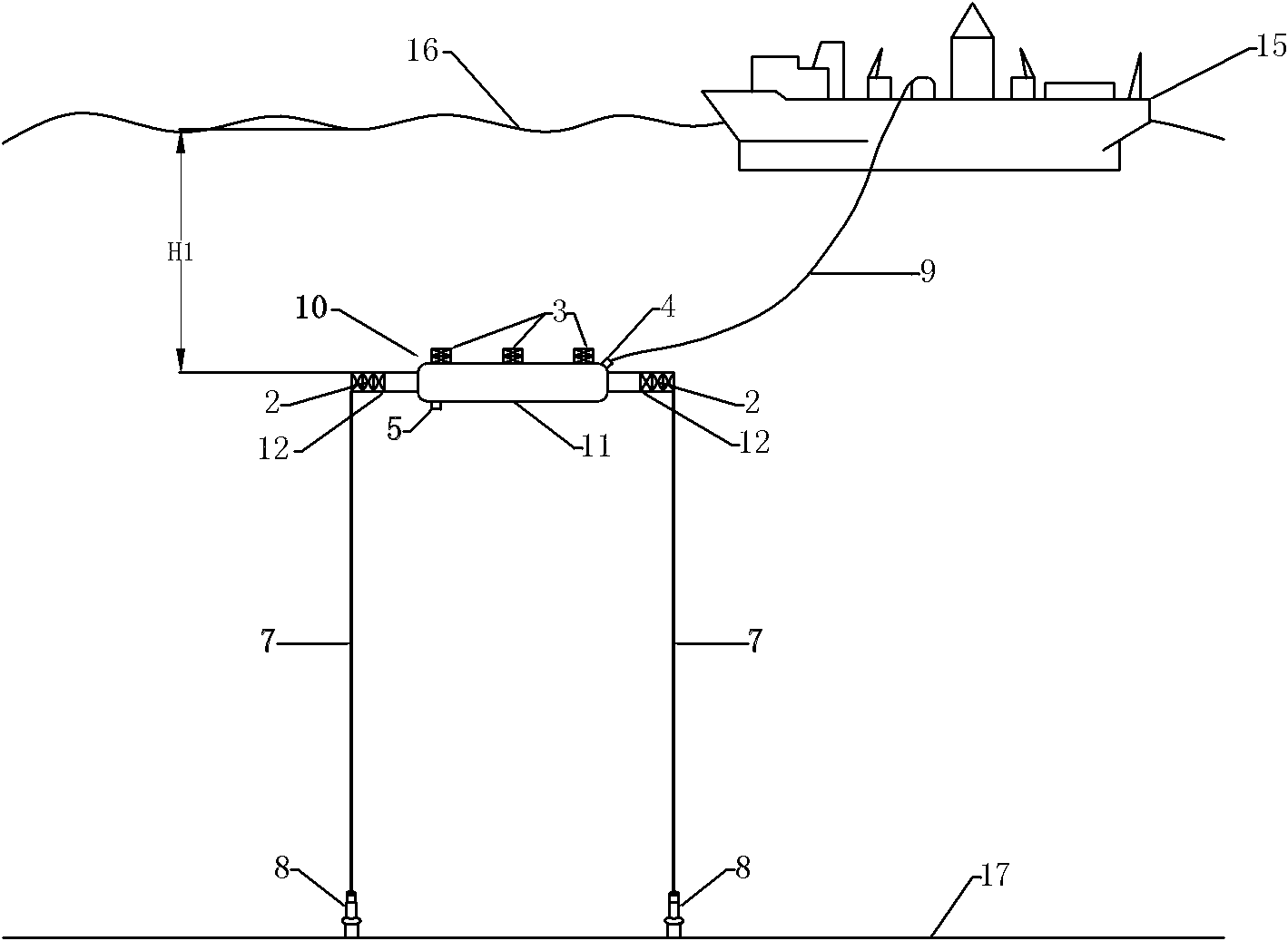

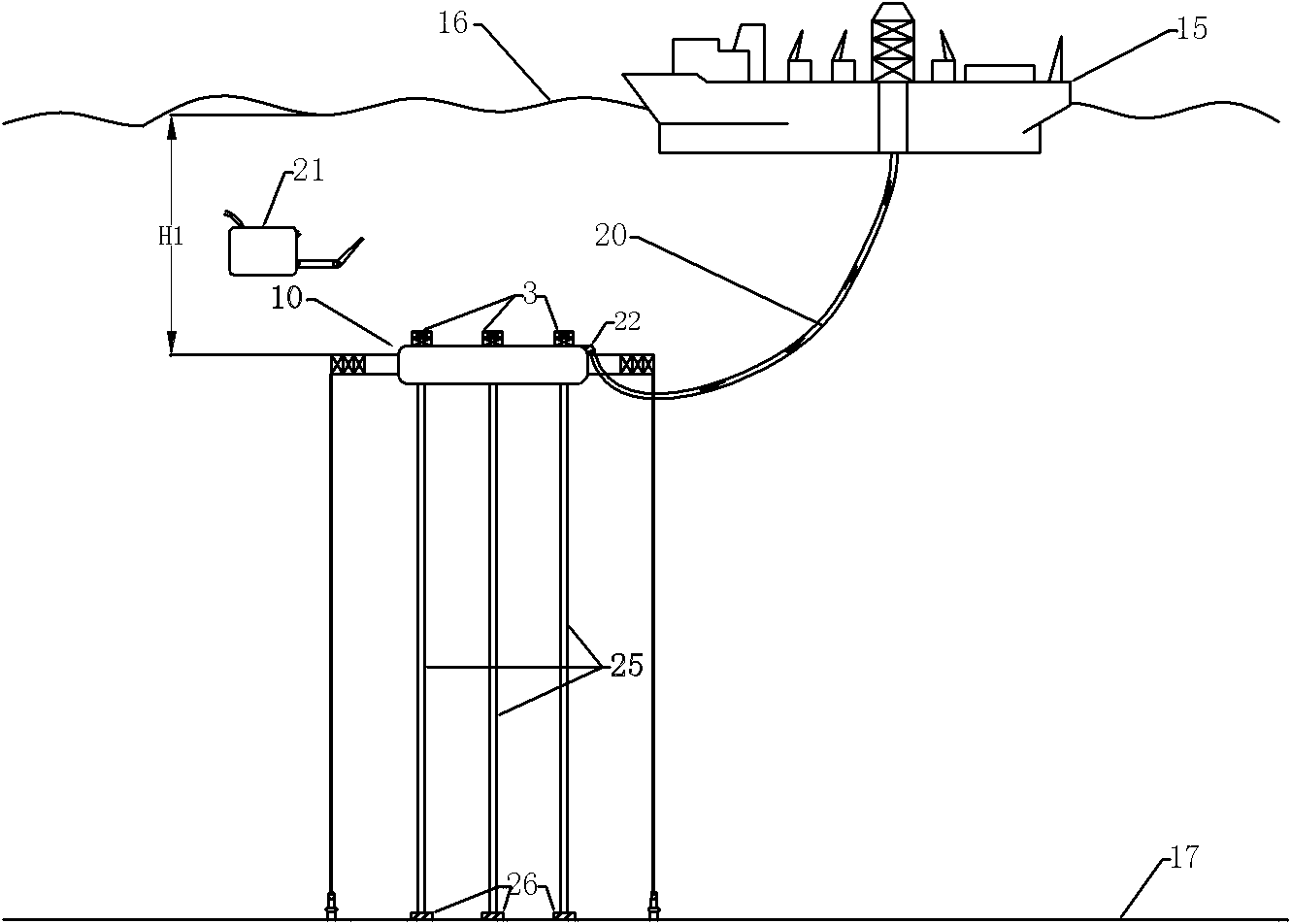

[0024] Such as figure 1 As shown, an ultra-deep sea underwater riser support device includes a riser support buoy 10, a tension mooring device and an umbilical cable 9.

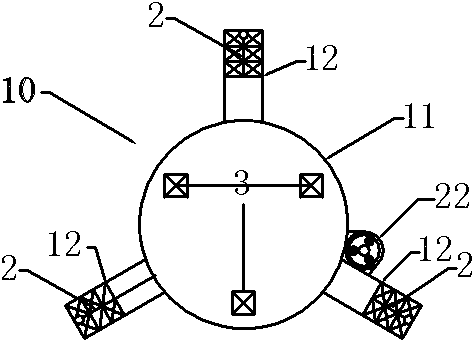

[0025] Such as Figure 1-2 As shown, the riser support buoy 10 is a starfish-like structure, that is, the central column structure buoy 11 is connected to three cantilever buoys 12 with a rectangular cross-section at the edge, and their included angle on the plane is 120°, forming a radial shape. The end of the cantilever buoy 12 adopts a neutrally buoyant truss structure 2 . When the design requires an additional increase in the buoyancy of the riser support buoy 10, it is only necessary to reduce the proportional length of the truss structure 2 on the cantilever buoy 12 or increase the length of the cantilever buoy 12; if the design buoyancy requirements are met, the truss can be increased The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com