Mesoporous magnetic ferriferrous oxide, its preparation method and application

A ferric tetroxide, magnetic technology, applied in the direction of iron oxide/iron hydroxide, ferrous oxide, inorganic inactive ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

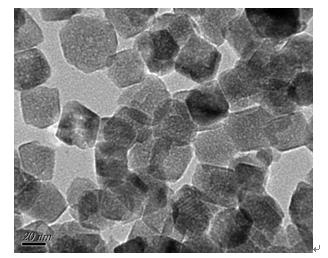

[0015] Example 1 (example of optimal reaction conditions):

[0016] Weigh 10.032g FeCl 3 ·6H 2 O (0.037mol) and 2ml ethylene glycol (molar ratio 1:1), stir to form a clear yellow solution, then add 3.0017g NaAc, 7.6ml ethylenetriamine (in which FeCl 3 ·6H 2 The molar ratio of O:NaAc:amine is 1:1:2), in the reaction kettle, 120 ℃, react for 6 hours, naturally cooled to room temperature, centrifuged, washed with water 4 times, and dried to obtain 8.42 g of black solid particles, the yield, 84%, particle size 15-20 nm. Surface area is 21.04 m 2 / g, the pore size is 9.50 nm. IR cm -1 : 582: vibration absorption peak of Fe-O bond, 1571: N-H in-plane deformation vibration, 3404: N-H asymmetric stretching vibration.

Embodiment 2

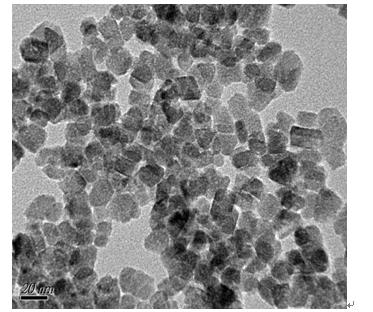

[0018] Preparation of mesoporous magnetic ferric oxide: Weigh 10.032g FeCl 3 ·6H 2 O (0.037mol) and 2ml ethylene glycol (molar ratio 1:1), stir to form a clear yellow solution, then add 3.0017g NaAc, 3.8ml ethylenetriamine (in which FeCl 3 ·6H 2 The molar ratio of O:NaAc:amine is 1:1:1), in the reaction kettle, 180 ℃, react for 4 hours, naturally cooled to room temperature, centrifuged, washed 4 times with water, and dried to obtain 6.21 g of black solid particles with a yield of 62 %.

Embodiment 3

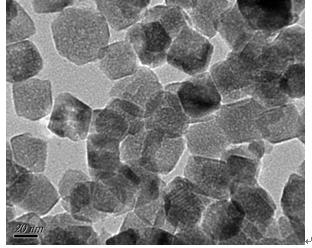

[0020] Preparation of mesoporous magnetic ferric oxide: Weigh 10.032g FeCl 3 ·6H 2 O (0.037mol) and 2ml ethylene glycol (molar ratio 1:1), stir to form a clear yellow solution, then add 3.0017g NaAc, 22.4ml ethylenetriamine ((FeCl 3 ·6H 2 O:NaAc:Amine molar ratio is 1:1:6), in the reaction kettle, 110 ℃, react for 6 hours, naturally cooled to room temperature, centrifuged, washed 4 times with water, dried to obtain black solid particles 5.67g, yield 56 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com