Brake control method of automobile brake-by-wire system and electric brake

An electric brake and brake control technology, applied in electric braking systems, brakes, electric vehicles, etc., can solve the problems of high price, poor braking accuracy, slow braking response, etc., and achieve simple structure, reliable braking, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

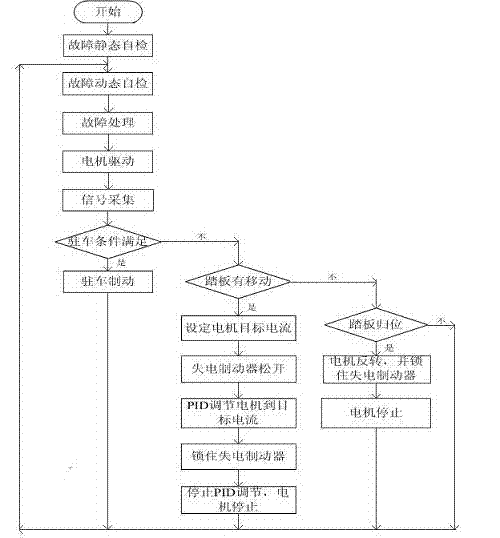

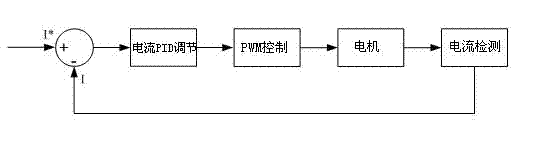

[0018] Such as figure 1 As shown, each wheel is equipped with an electric brake and a wheel speed sensor. Such as Figure 4 As shown, the electric brake includes a brake caliper body 1, a motor 7, and also includes a lead screw 3 and a lead screw nut 2. The motor can drive the lead screw nut 2 to rotate through the reduction mechanism 5, and the lead screw nut drives the lead screw to perform a feed movement. brake. The end of the output shaft of the motor is provided with a power-off brake 6 . The outer end of the leading screw is provided with a butterfly spring 4.

[0019] During the braking operation, the power-off brake 6 is energized, and the motor 7 rotates forward to output torque. After the torque is decelerated by the deceleration mechanism 5 and the torque is increased, the torque is transmitted to the lead screw nut 2, and the lead screw nut 2 rotates to drive the feed movement of the lead screw 3. . At the same time, when the de-energized brake 6 is energized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com