Treatment process of injecting product in mold

An in-mold injection molding and processing technology, which is applied in the field of surface treatment, can solve the problems of inability to process sharp and angular structures, weak three-dimensional effect, and low efficiency, so as to ensure the pattern and aesthetics, product beauty, and enhance competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

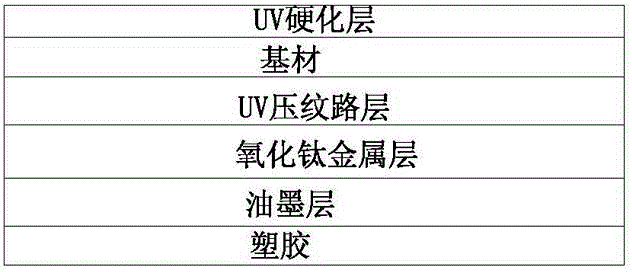

Image

Examples

Embodiment 1

[0024] Embodiment one, (1) select the PET sheet material that thickness is 0.1mm as base material for use, coat UV topcoat on one of the surfaces of this base material, temperature is 17 ℃ when coating UV topcoat, and humidity is 55% , and then put the base material in a curing oven for curing, so that the surface of the base material is hardened to form a UV cured layer, and the thickness of the UV cured layer is 3 μm. (2) On the other surface of the substrate, that is, the symmetrical surface of the UV hardened layer, apply UV topcoat, and die-cast lines on the UV topcoat. The pressure value during die-casting is 10000Pa, and then the substrate is Curing makes the surface of the substrate form a UV texture layer, and the thickness of the UV texture layer is 3 μm. (3) Vacuum sputtering is carried out on the UV texture layer, the target material is titanium oxide, so that a translucent titanium oxide metal layer is formed on the UV texture layer, and the vacuum pressure during...

Embodiment 2

[0025] Embodiment two, (1) select the PET sheet material that thickness is 0.125mm as base material for use, coat UV topcoat on one of the surfaces of this base material, when coating UV topcoat, temperature is 20 ℃, and humidity is 60% , and then put the base material in a curing furnace for curing, so that the surface of the base material is hardened to form a UV hardening layer, and the thickness of the UV hardening layer is 3.5 μm. (2) On the other surface of the substrate, that is, the symmetrical surface of the UV hardened layer, apply UV topcoat, and die-cast lines on the UV topcoat. The pressure value during die-casting is 10000Pa, and then the substrate is Curing causes the surface of the substrate to form a UV textured layer, and the thickness of the UV textured layer is 3.5 μm. (3) Vacuum sputtering is carried out on the UV texture layer, the target material is titanium oxide, so that a translucent titanium oxide metal layer is formed on the UV texture layer, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com