Municipal solid waste compressive classification treatment method

A technology of municipal solid waste and treatment methods, which is applied in the field of comprehensive classification and treatment of municipal solid waste, and can solve problems such as complex components of waste, uneven calorific value, and irregular bag reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

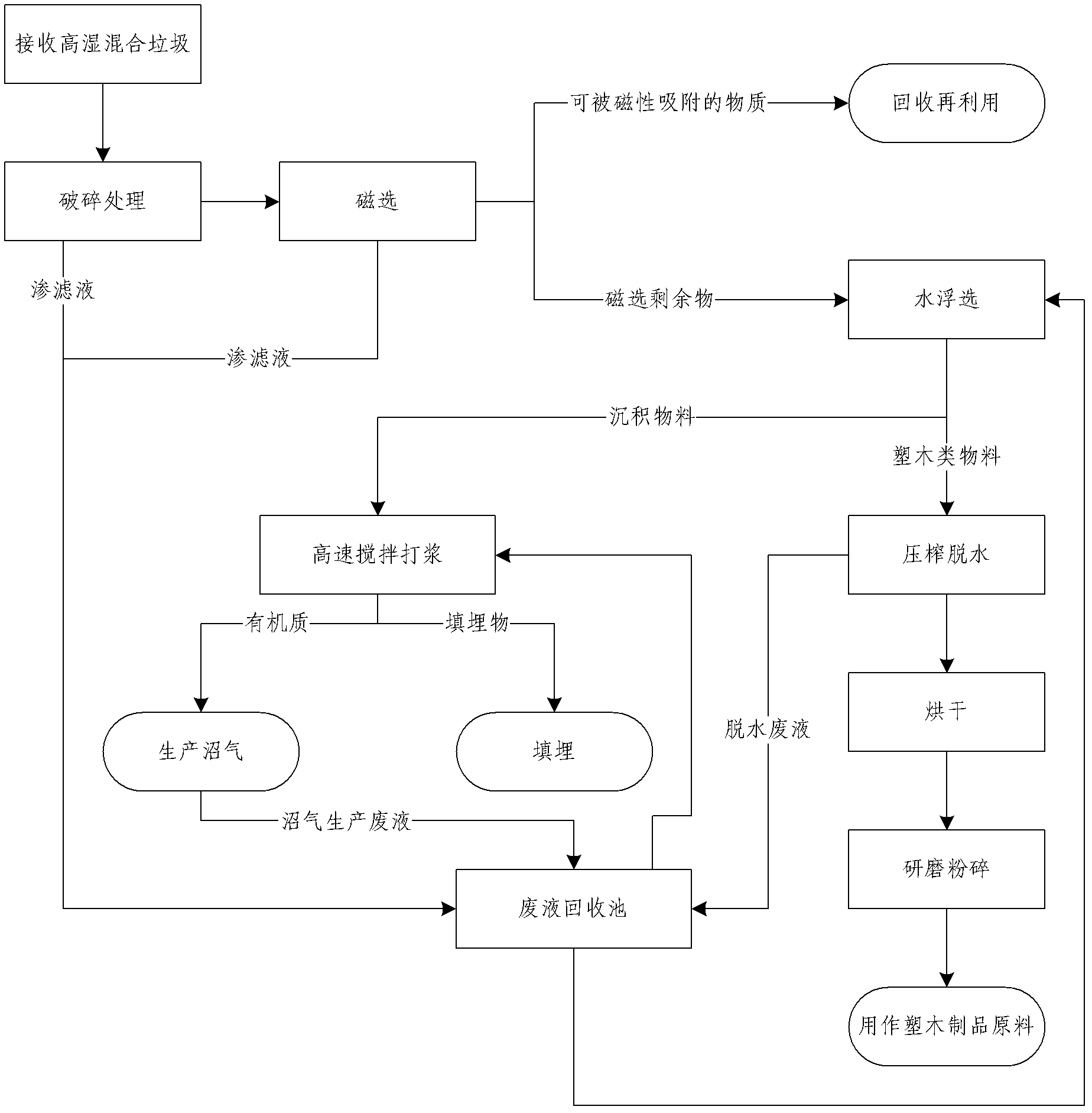

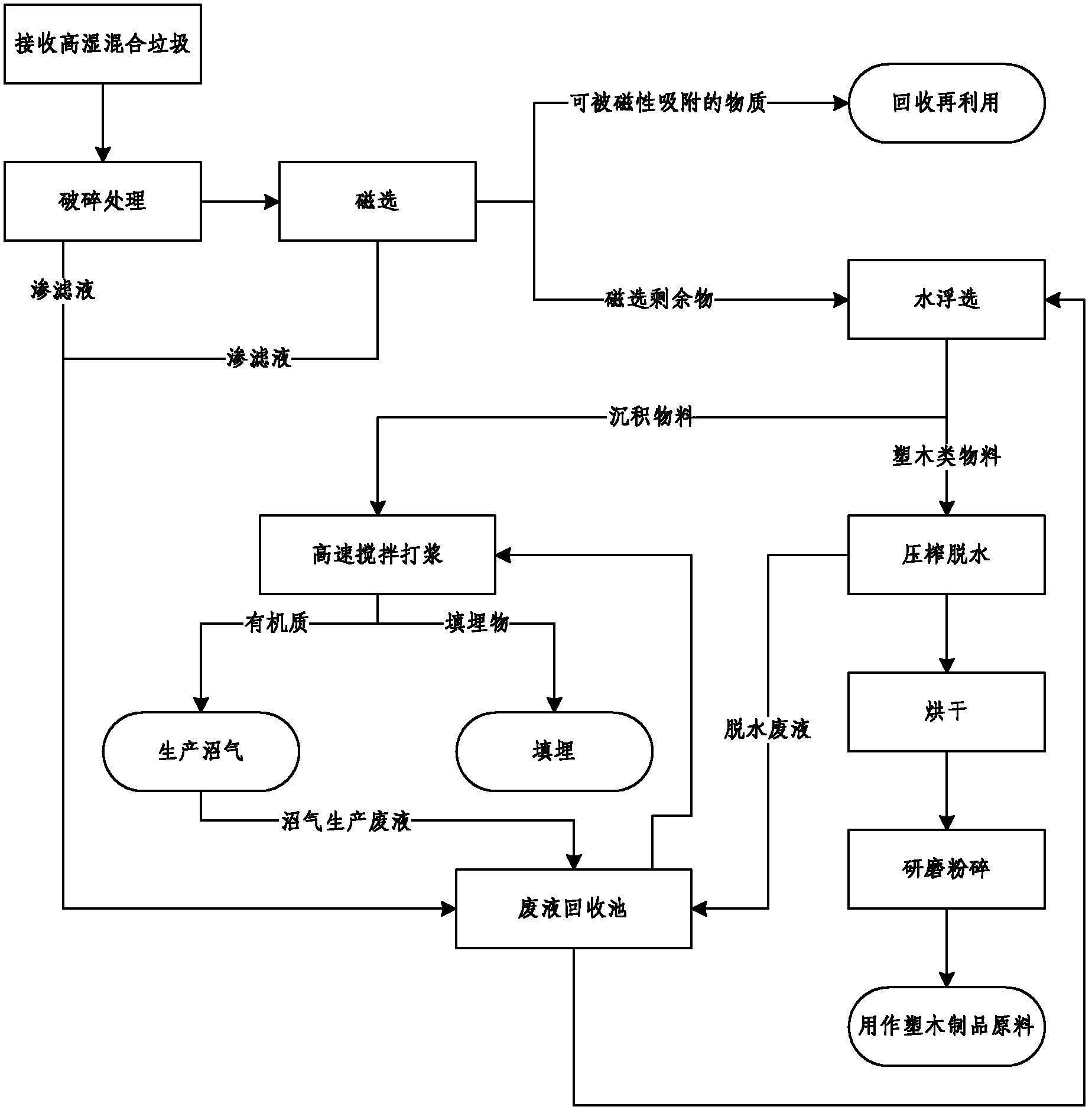

[0021] Please refer to figure 1 The flow chart of one embodiment of the present invention shown, the present invention provides a kind of municipal solid waste comprehensive classification processing method, comprises the following steps:

[0022] In the crushing step, the collected high-humidity mixed garbage is transported into a double-shaft crusher for bag breaking and crushing, and the garbage is broken into flocculent substances with a block size of no more than 100mm;

[0023] In the magnetic separation step, the material from the crusher is sent to the magnetic separation belt conveyor, and the magnetic suction sorts out the magnetically adsorbed material. In order to more efficiently and comprehensively sort out the magnetically adsorbed material, preferably, the The magnetic field strength of the magnetic separation belt conveyor is greater than 2500GS;

[0024] In the water flotation step, the residue treated by magnetic separation is transported into the flotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com