Heated mixture of soy sauce and sugar, and fatty food

A technology for mixtures and sugars, applied in the field of oily foods, can solve the problem of not getting the taste and ripening feeling, and achieve the effects of stable emulsification, excellent emulsifying ability and solubilizing ability, and high suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-8

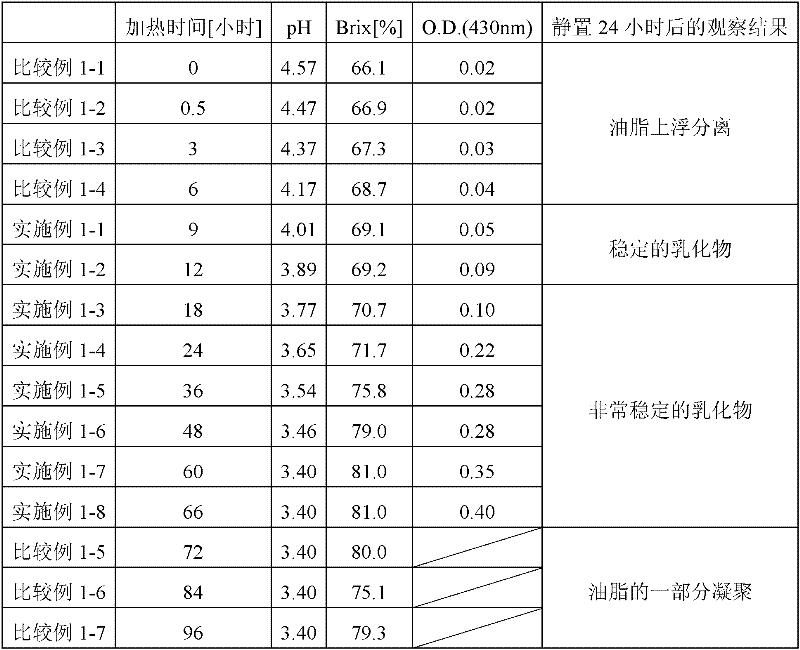

[0073] [Examples 1-1 to 1-8, Comparative Examples 1-1 to 1-7]

[0074] (Preparation of heating mixture of soy sauce and sugar)

[0075] Commercially available thick soy sauce (total nitrogen concentration: 1.65% (w / v)) was permeated with a reverse osmosis membrane (NTR-7450: manufactured by Nitto Denko Co., Ltd.), and the membrane obtained by separating from the non-permeation side 500 ml of concentrated soy sauce (total nitrogen concentration: 2.0% (w / v)) was mixed with 500 g of glucose (anhydrous conversion) to prepare a mixed aqueous solution of soy sauce and sugar. This mixed aqueous solution was heated at a liquid temperature of 85° C. for 0 to 96 hours to obtain heated mixtures of soy sauce and saccharides having different emulsifying abilities.

[0076] (measurement method of color)

[0077] The color of each obtained heated mixture of soy sauce and saccharides was measured. In the color measurement, the absorbance at 430 nm of a 0.1% (w / w) aqueous dilution was measu...

Embodiment 1-9

[0085] (Preparation of heating mixture of soy sauce and sugar, and manufacture of emulsified oil and fat food)

[0086] 500 ml of commercially available soy sauce (total nitrogen concentration: 2.2% (w / v)) was mixed with 500 g of glucose (anhydrous conversion) to prepare a mixed aqueous solution of soy sauce and sugar. This soy sauce sugar mixed aqueous solution was heated at a liquid temperature of 80° C. for 48 hours to obtain a heated soy sauce sugar mixture having an absorbance at 430 nm of 0.40 in a 0.1% (w / w) water dilution (1,000 times water dilution).

[0087] 7 g of water was mixed with 13 g of this soy sauce saccharide heating mixture, 20 g of oils and fats were added, and it stirred at high speed (16,000 rpm, 30 seconds) with the homogenizer, and obtained the emulsified oil-fat food. After preparing the emulsified oil and fat food, it was left to stand for 24 hours, and the state of emulsification and dispersion was visually confirmed. The obtained soy sauce sugar ...

Embodiment 2

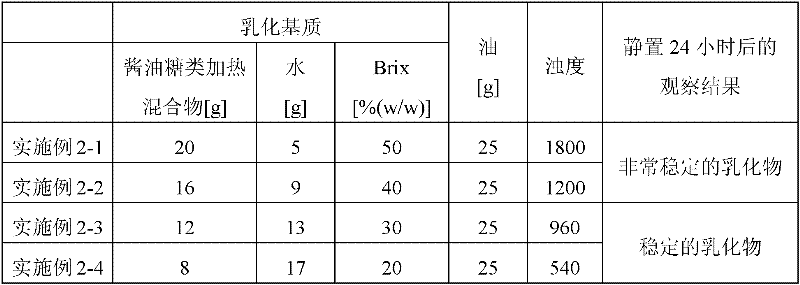

[0090] (Preparation of heating mixture of soy sauce and sugar)

[0091] Commercially available thick soy sauce (total nitrogen concentration: 1.65% (w / v)) was permeated with a reverse osmosis membrane (NTR-7450: manufactured by Nitto Denko Co., Ltd.), and the membrane obtained by separating from the non-permeation side 500 ml of concentrated soy sauce (total nitrogen concentration: 2.0% (w / v)) was mixed with 500 g of glucose (anhydrous conversion) to prepare a mixed aqueous solution of soy sauce and sugar. The mixed aqueous solution was heated at a liquid temperature of 85° C. for 48 hours to obtain a 0.1% (w / w) water dilution (1,000 times water dilution) with a Brix of 62% (w / w) having an absorbance of 0.28 at 430 nm. Soy sauce sugar heat mixture.

[0092] (Manufacture of emulsified oil and fat food)

[0093] Water was added to the above-mentioned soy sauce saccharide heating mixture at the ratio described in the following Table 2 to prepare an emulsified base. The same am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com