Combined driving micro-displacement regulation device

A combination of drive and adjustment device technology, applied in the direction of position/direction control, control/regulation system, non-electric variable control, etc., can solve the problems of unstable transmission, high noise, low transmission efficiency, etc., and achieve stable transmission and displacement , The effect of smooth displacement adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The combined drive micro-displacement adjusting device of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but this should not limit the protection scope of the present invention.

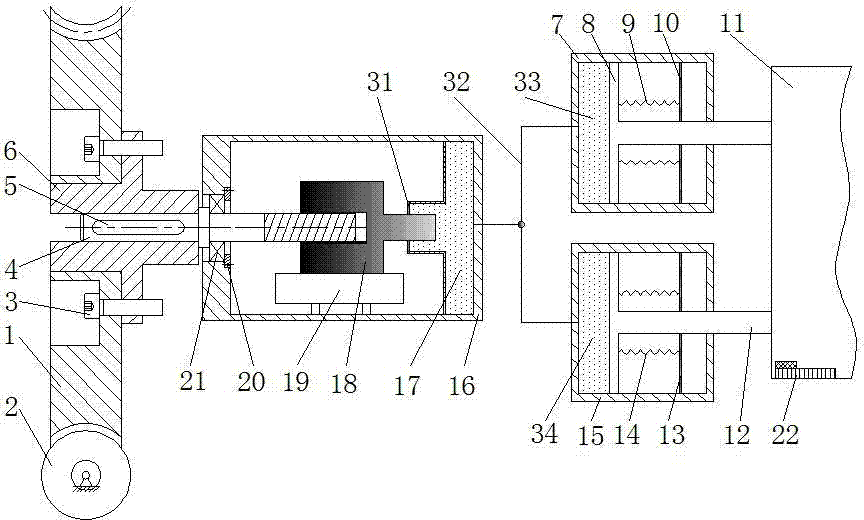

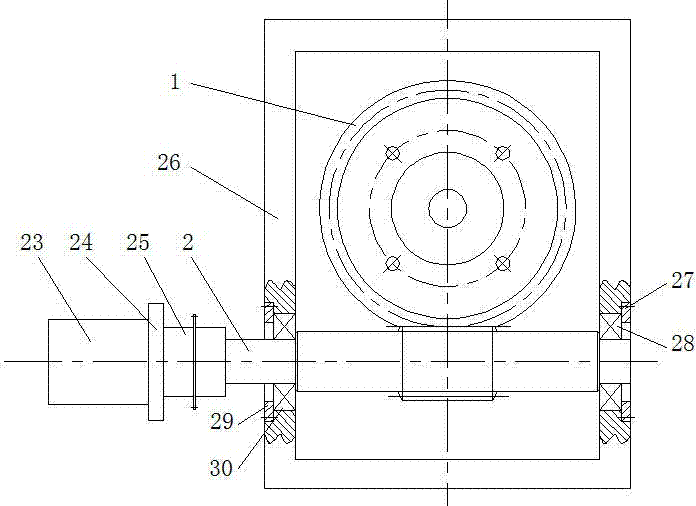

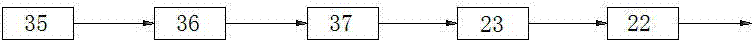

[0035]see first Figure 1-Figure 2 shown. figure 1 It is a cross-sectional view of the overall structure of the combined drive micro-displacement adjustment device of the present invention. figure 2 It is a partial view of the worm gear transmission module in the present invention. Depend on Figure 1-Figure 2 It can be seen that the combined drive micro-displacement adjustment device of the present invention includes a worm gear transmission module, a worm gear shaft 6, a rotating shaft 4, a screw 3, a key 5, a rolling bearing 21, a grating ruler 22, a bearing retaining ring 20, a nut 18, a slider 19, a shell Body 16, third oil cylinder 17, two hydraulic transmission modules and workbench 11. in:

[0036] The worm gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com