Impingement plate structure of heat exchanger

A technology of anti-shock plate and heat exchanger, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. Heat exchanger heat exchange tube and other problems, to prevent up and down jitter, ensure normal operation, and reduce the effect of jitter amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

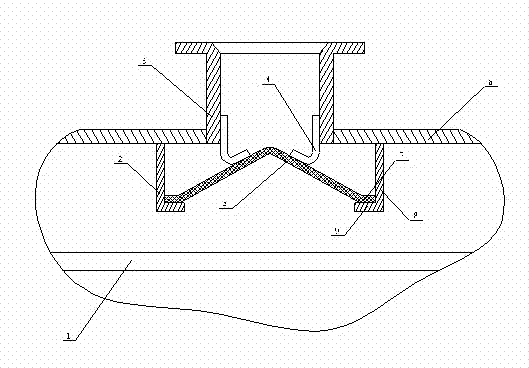

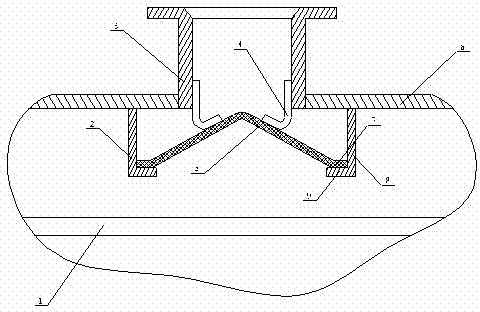

[0013] as attached figure 2 Shown is a structure of a heat exchanger anti-shock plate according to the present invention, including an inlet connecting pipe 3, an anti-shock plate 5 and a rib plate 2; the lower end of the inlet connecting pipe 3 is welded on the shell 6 of the heat exchanger; The anti-scouring plate 5 is fixed directly below the inlet connecting pipe 3 through the two ribs 2 at the lower end of the inlet connecting pipe 3, and the anti-scouring plate 5 is located above the heat exchange tube 1; the section of the anti-scouring plate 5 is inverted V-shaped, and the two ends of the impact plate 5 are extended with convex plates 7; the cross-section of the rib plate 2 is L-shaped, and it includes a long side 8 and a short side 9; the upper end of the rib plate 2 is welded On the inner side wall of the shell 6, and the long side 8 of the rib plate 2 is perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com