Self-operated T-shaped pneumatic rapid cut-off valve

A quick cut-off, self-operated technology, applied in the direction of valve lift, valve detail, valve device, etc., can solve problems such as easy wear, wear, and impact on service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

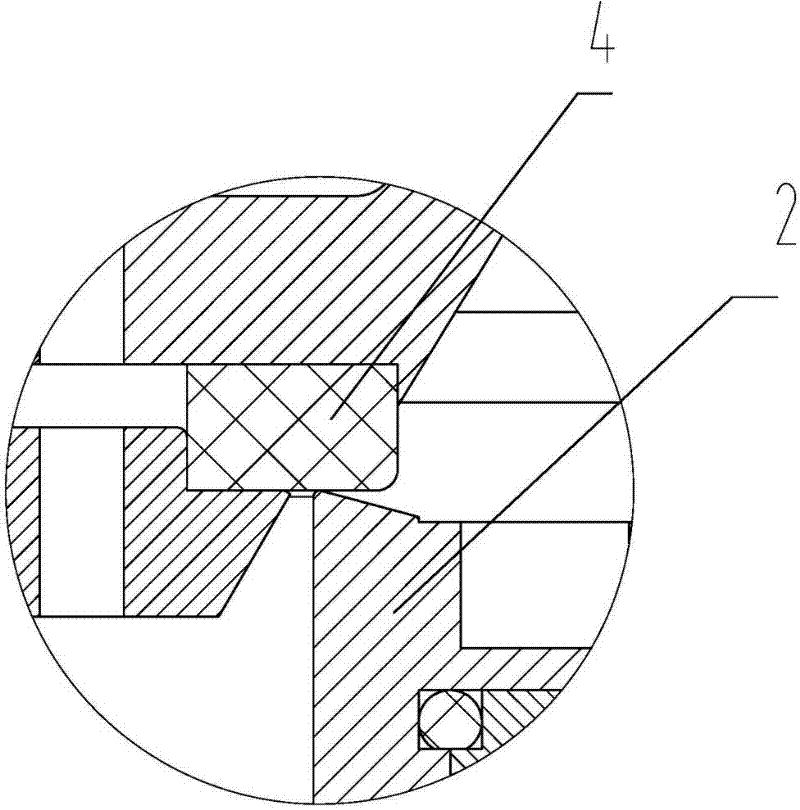

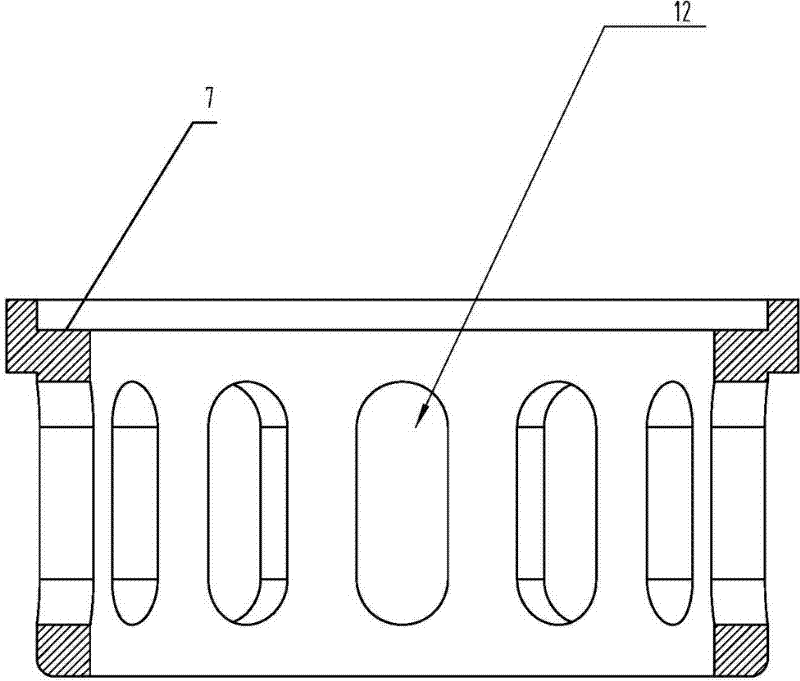

[0011] like Figure 1-Figure 3 As shown, the self-operated T-type pneumatic quick cut-off valve includes valve body 1, valve seat 2, pneumatic actuator head 9, piston rod 10, sealing ring 6, connecting body 8, spring 11, valve body 1 is provided with a valve seat 2. A cylinder liner 5 is provided on the valve seat 2, a sealing seat 4 is provided between the valve seat and the cylinder liner, a sealing seat gland 3 is provided on the sealing seat 4, and a cylinder liner is provided between the top of the cylinder liner and the valve body 1 The guide sleeve 7, that is, the cylinder liner guide sleeve 7 is set above the sealing seat 4; the valve seat at the contact point between the valve seat 2 and the sealing seat 4 is designed as an inclined plane, and the plane of the sealing seat is in line contact; the inner side of the cylinder liner guide sleeve passes through the seal The ring 6 is connected to the connecting body 8 . The cylinder liner guide sleeve 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com