Multi-hopper pile die for pipe sinking cast-in-place pile and construction method

A technology of immersed tube grouting piles and multiple hoppers, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased force of concrete lateral extrusion, increased possibility of segregation, waste of concrete energy, etc. Achieve the effects of reducing the drop height, saving materials and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

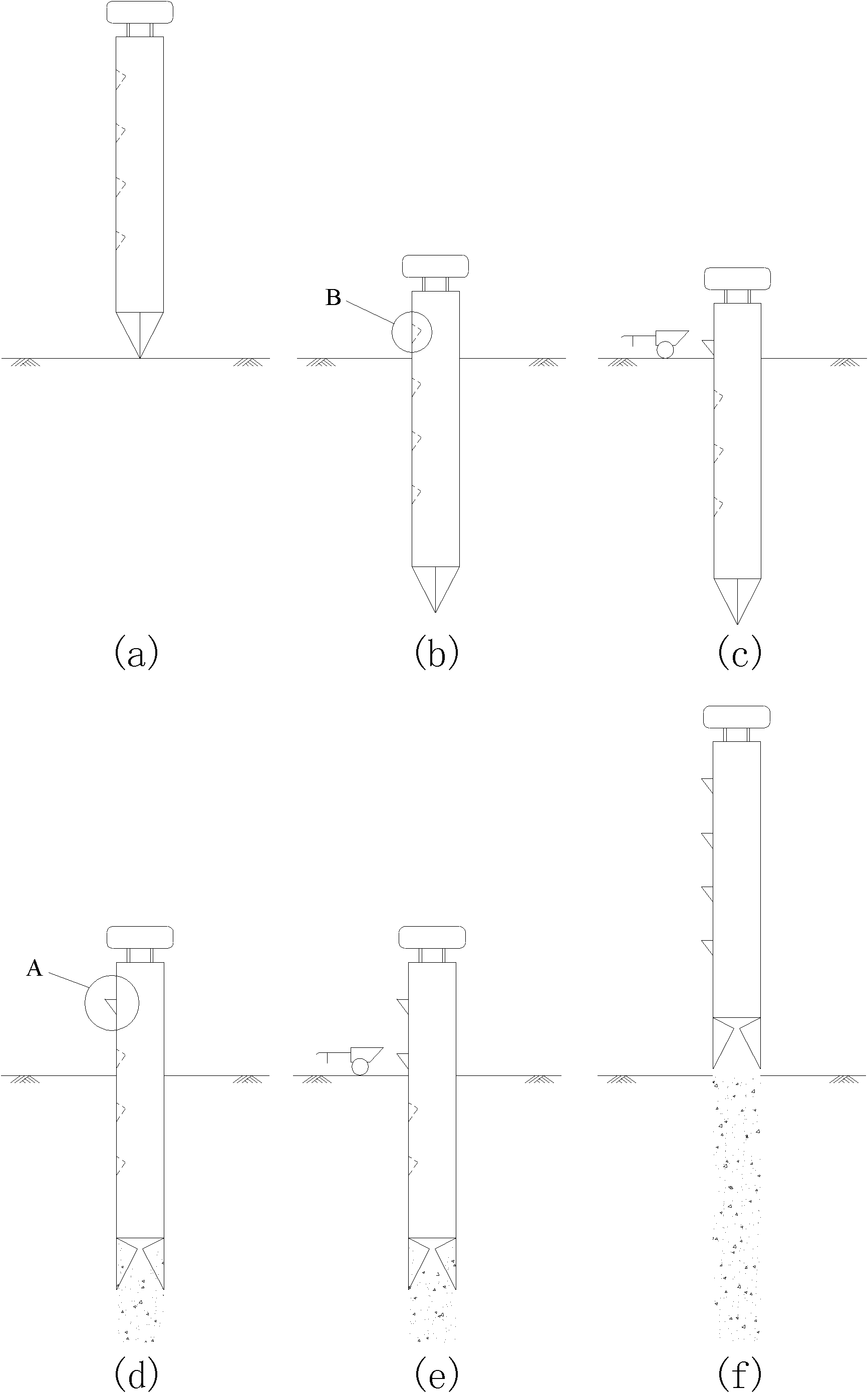

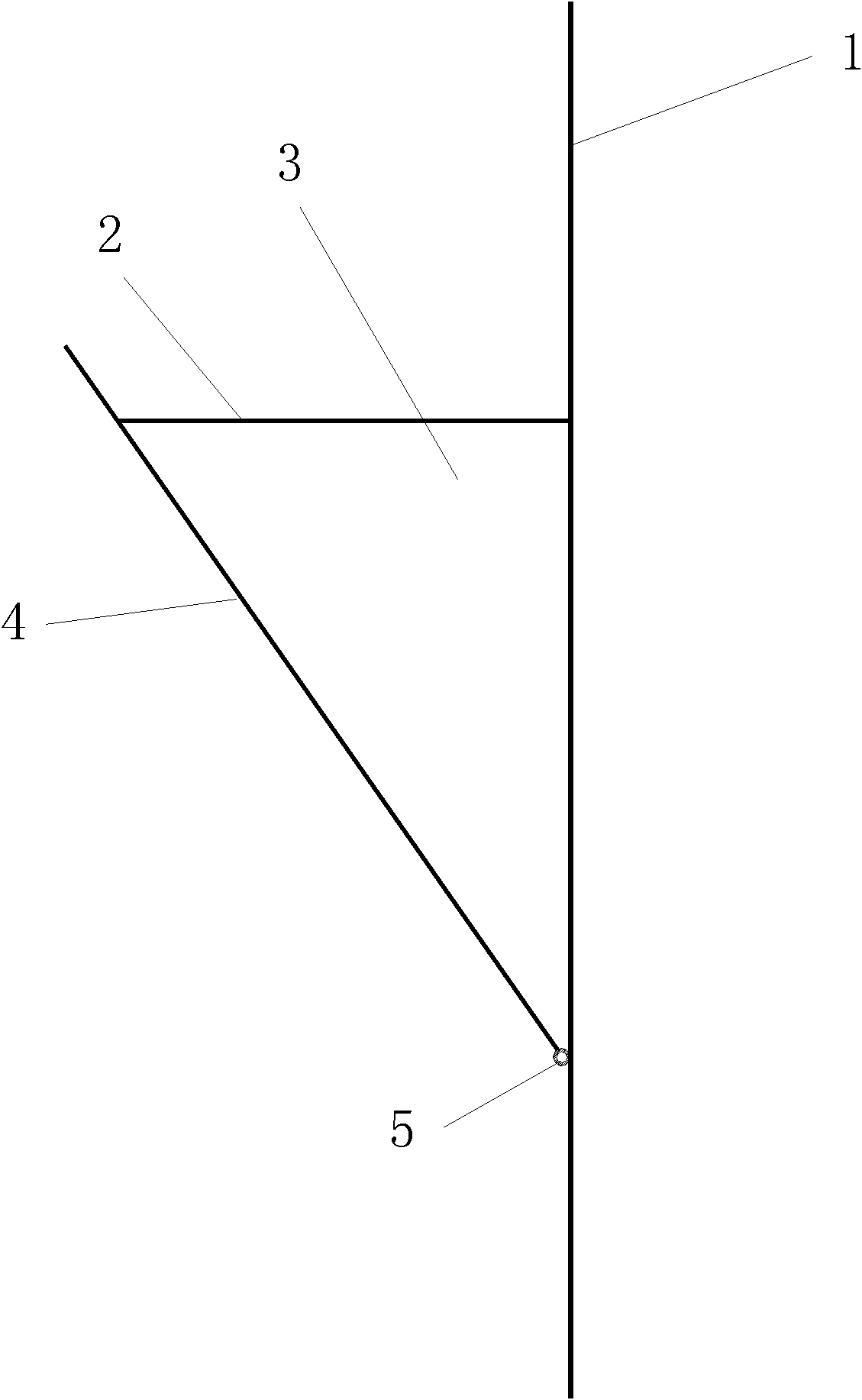

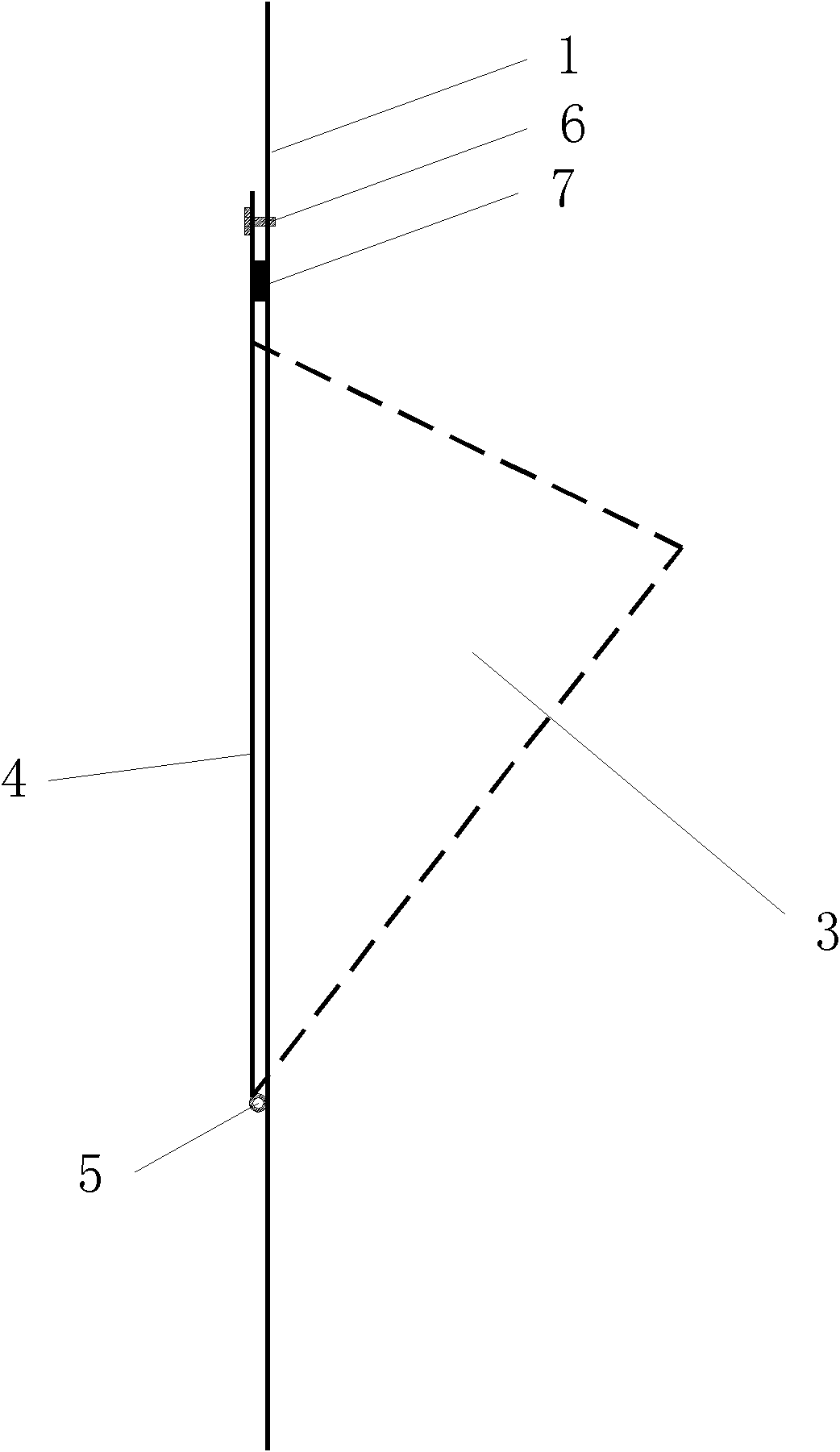

[0036] Such as Figure 1~Figure 7 As shown in the figure, a multi-hopper pile formwork for immersed tube grouting piles, two or more movable feeding hoppers (2) are arranged on the outer wall of the pile formwork (1), and the movable feeding hoppers (2) are composed of side steel plates (3), The front steel plate (4) and the movable hinge (5) are composed of structures, and are fixed by the fixing bolts (6) and the pile formwork (1) when closed, and the sealing ring (7) is set between the front steel plate (4) and the pile formwork (1) ). Each movable feeding hopper (2) is composed of a front steel plate (4) and two side steel plates (3). Greater than the radius of the pile formwork (1), its area is greater than the area of the feed opening (9), and the side steel plates (3) are located on both sides of the movable feed hopper (2) and are triangular. When the movable feeding hopper (2) is opened, a bending section (8) is arranged near the side of the pile formwork (1). Ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com