High-strength high-carbon steel wire rod and production method thereof

A production method and high-carbon steel technology, which are applied in the field of high-strength and high-carbon steel wire rods and their production fields, can solve problems such as unfavorable market competitiveness of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below by way of examples.

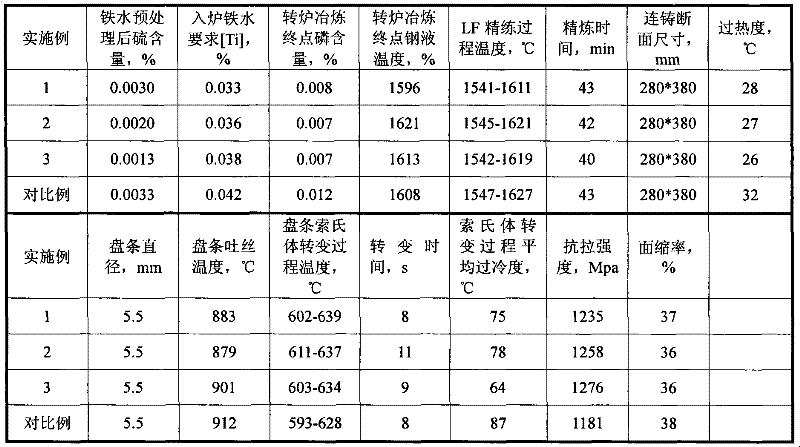

[0015] Table 1 shows the chemical composition of the high-strength high-carbon steel wire rod of the embodiment of the present invention, and Table 2 shows the production process and performance of the high-strength high-carbon steel wire rod of the embodiment of the present invention.

[0016] Table 1 The chemical composition (Wt%) of the high carbon steel wire rod of the embodiment of the present invention

[0017] Example

C

Si

mn

P

S

Ti

1

0.85

0.30

0.48

0.011

0.007

0.0009

2

0.87

0.28

0.55

0.010

0.006

0.0005

3

0.90

0.25

0.52

0.012

0.005

0.0008

comparative example

0.81

0.25

0.49

0.017

0.011

0.0021

[0018] Table 2 Production technology and performance of the high carbon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com