Method of regulating polypropylene crystallization behavior and crystal structure

A crystalline structure, polypropylene technology, applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, instruments, etc., can solve the problem of not being able to meet the needs of self-nucleation to regulate crystallization behavior, and unable to self-nucleate temperature Precise control, low temperature control precision and other problems, to achieve the effect of simple operation, high control precision and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

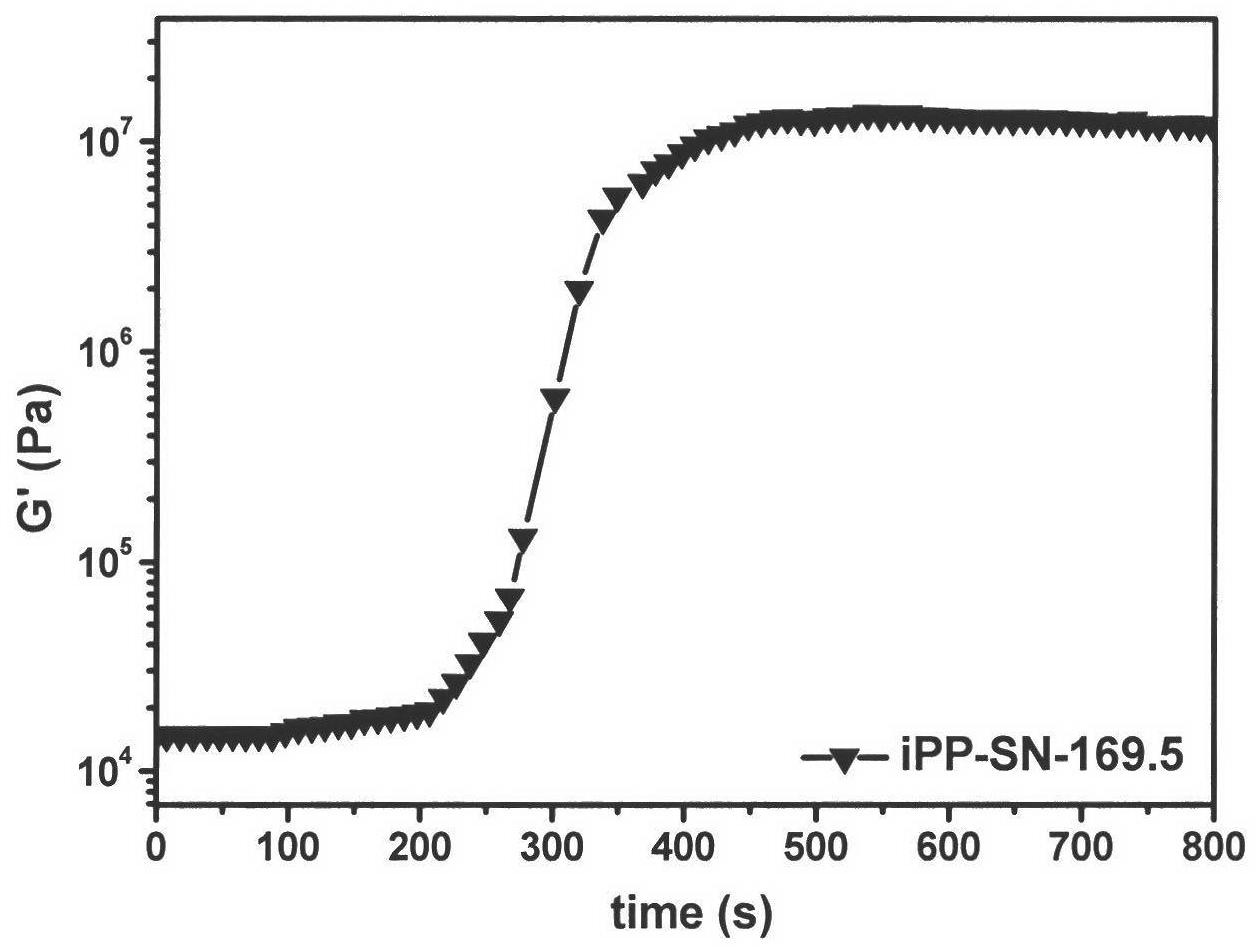

[0016] Isotactic polypropylene discs with a diameter of 25 mm were pressed in a hot press. The grade F401 homopolypropylene (manufactured by Yangzi Petrochemical Company) was heated to 200°C in the ARES rheometer and melted for 5 minutes, the distance between the plates was adjusted to 0.5mm, and the heating was stopped, so that the sample was naturally cooled to 50°C in the furnace. Then, slowly raise the temperature to 169.5° C., ensuring that the temperature will not overshoot during the heating process. Keep the temperature at 169.5°C for about 2 minutes, then execute the dynamic small-amplitude dynamic mode, cool the sample to 130°C for isothermal crystallization, and record the change of the storage modulus of the sample. The change curve of the isothermal crystallization modulus is as follows: figure 1 shown. As observed in the figure, the semi-crystallization time of isotactic polypropylene is about 300s. Using DSC to investigate the self-nucleating isotactic polypro...

Embodiment 2

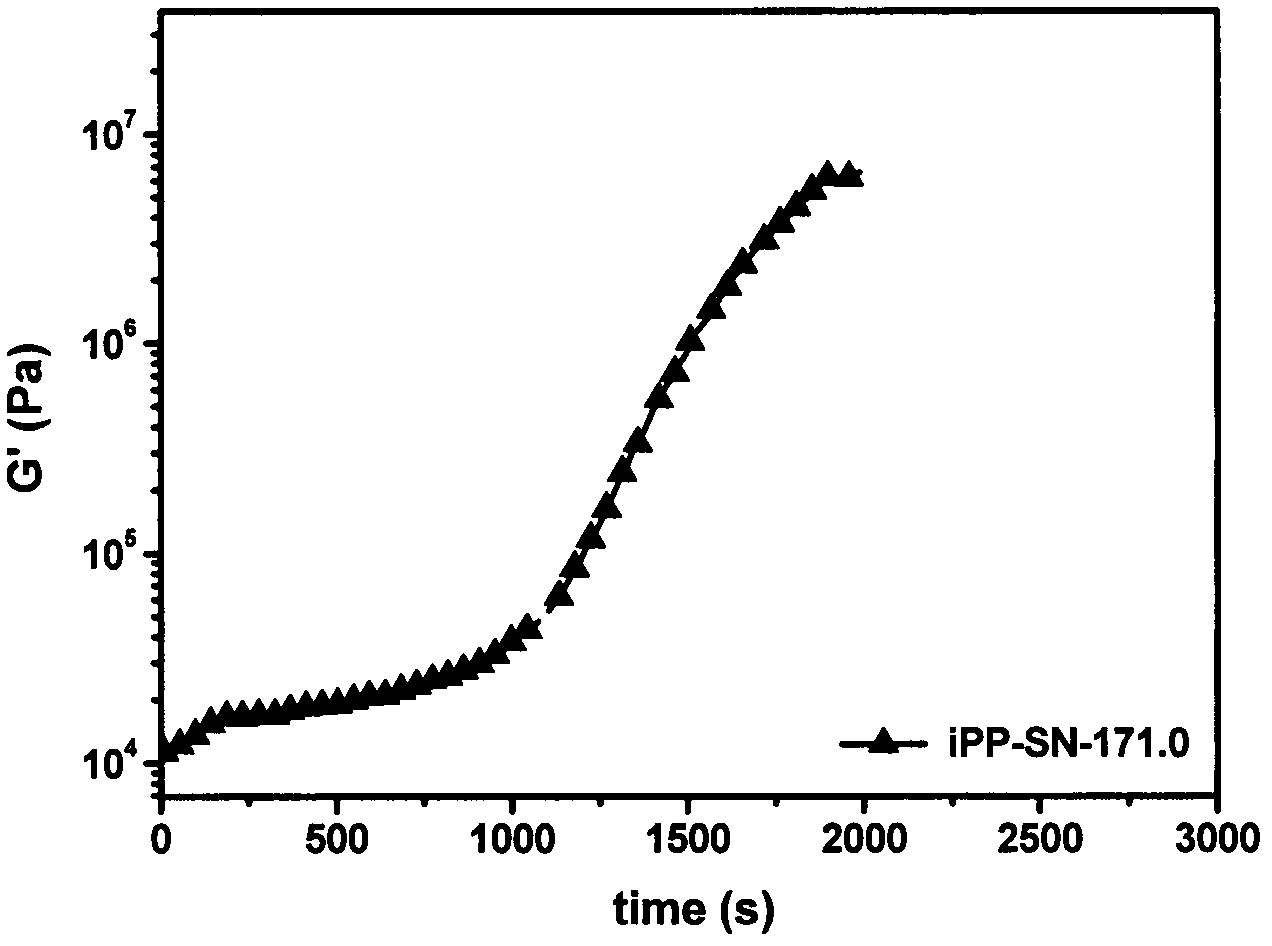

[0018] Isotactic polypropylene discs with a diameter of 25 mm were pressed in a hot press. The isotactic polypropylene sample was heated to 200°C and melted for 5 minutes in the ARES rheometer, the distance between the plates was adjusted to 0.5 mm, the heating was stopped, and the sample was naturally cooled to 50°C in the furnace. Then, slowly raise the temperature to 171.0° C. to ensure that the temperature will not overshoot during the heating process. Keep the temperature at 171.0°C for about 2 minutes, then execute the dynamic small-amplitude dynamic mode, cool the sample to 130°C for isothermal crystallization, and record the change of the storage modulus of the sample. The change curve of the isothermal crystallization modulus is as follows: image 3 shown. As observed in the figure, the half-crystallization time of isotactic polypropylene is about 1400s. Using DSC to investigate the self-nucleating isotactic polypropylene sample at 171.0 °C, the crystallization temp...

Embodiment 3

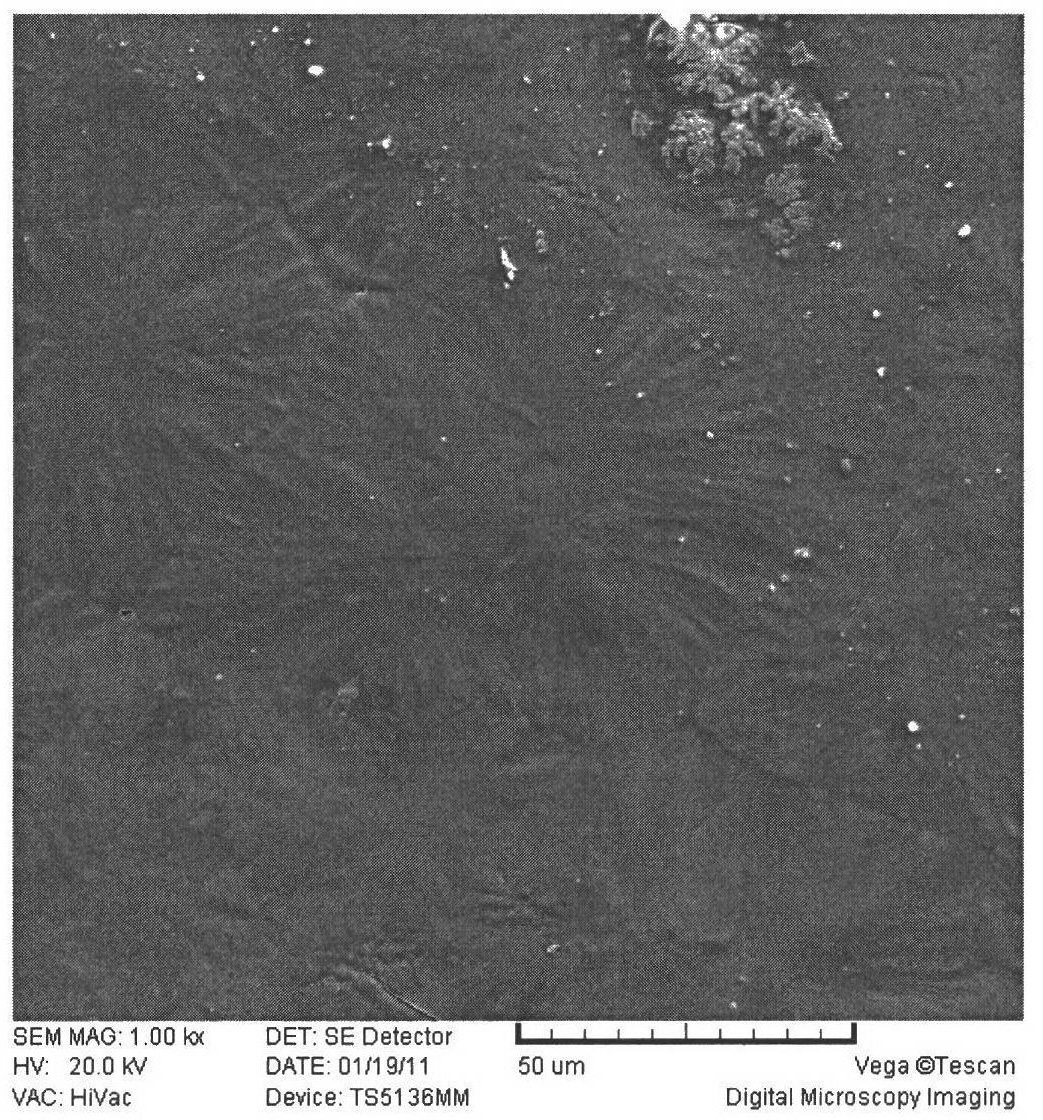

[0020] Others are the same as in Example 1, but the clamp diameter of the parallel plate rheometer used is 50 mm. The obtained spherulite diameter is about 45 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com