Rotary constant-speed water decanter

A decanter and rotary technology, applied in the field of rotary uniform decanters, can solve problems such as uneven decanting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

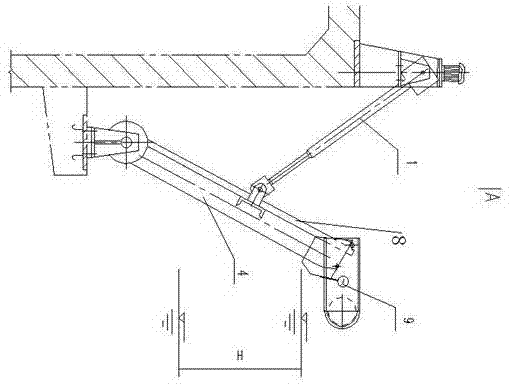

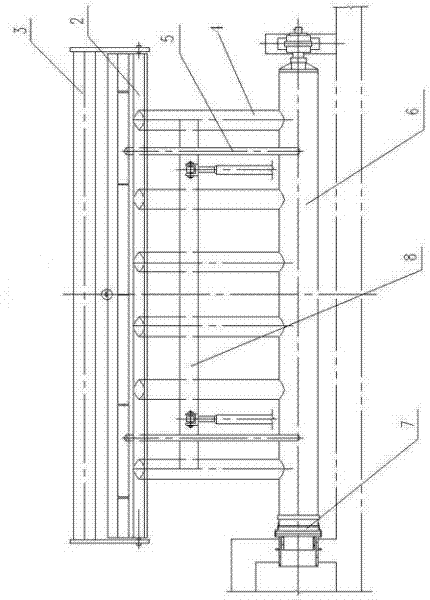

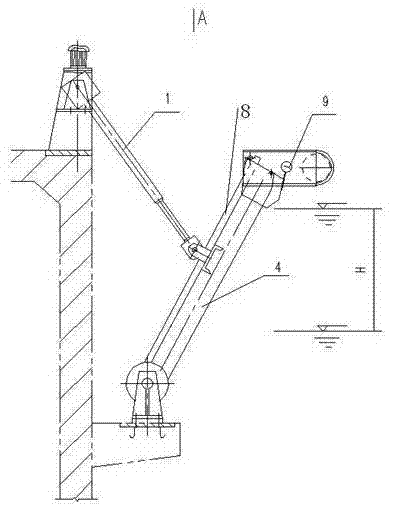

[0008] A rotary constant speed decanter, comprising a transmission device 1, a decanting tank 2, a skimming tank 3, a drainage branch pipe 4, an exhaust pipe 5, a main drain pipe 6, a slewing bearing 7, and the skimming tank 3 is connected to the decanting tank 2, The decanting tank 2, drainage branch pipe 4 and exhaust pipe 5 are fixed on the drainage main pipe 6, one end of the drainage main pipe 6 is inserted into the slewing bearing 7, one end of the transmission device 1 is hinged with the connecting rod 8 of the drainage branch pipe 4, and the other end is fixed by a trunnion On the frame, the transmission device 1 communicates with the controller signal in the control box, a liquid level probe 9 is arranged above the weir of the decanting tank 2, and a frequency converter is added in the control box. The liquid level probe 9, frequency converter and transmission Device 1 signal connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com