Lighter paper packaging equipment with automatic feeding and discharging functions

An automatic feeding and wrapping technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of troublesome post-processing, low work efficiency, chaotic accumulation, etc., to facilitate orderly arrangement, reduce labor, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

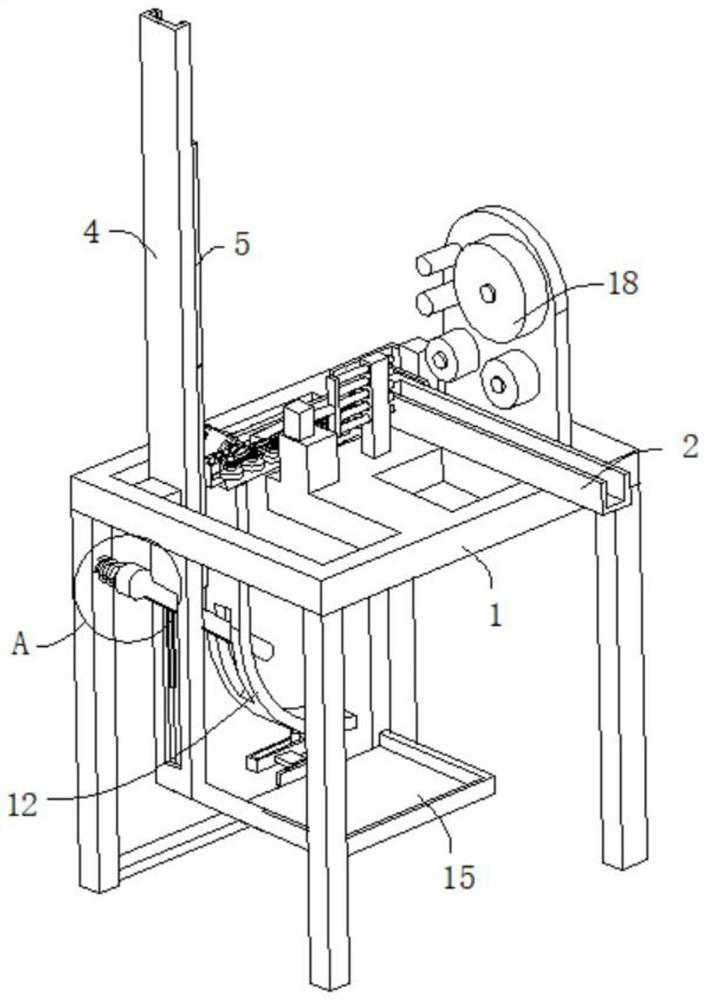

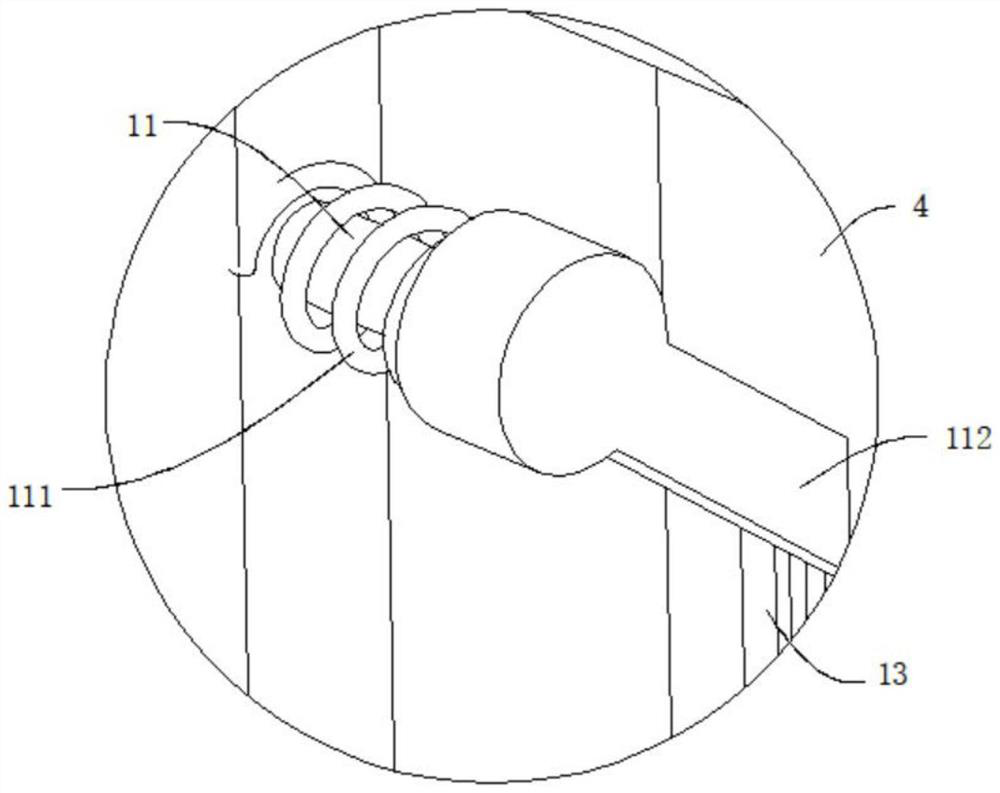

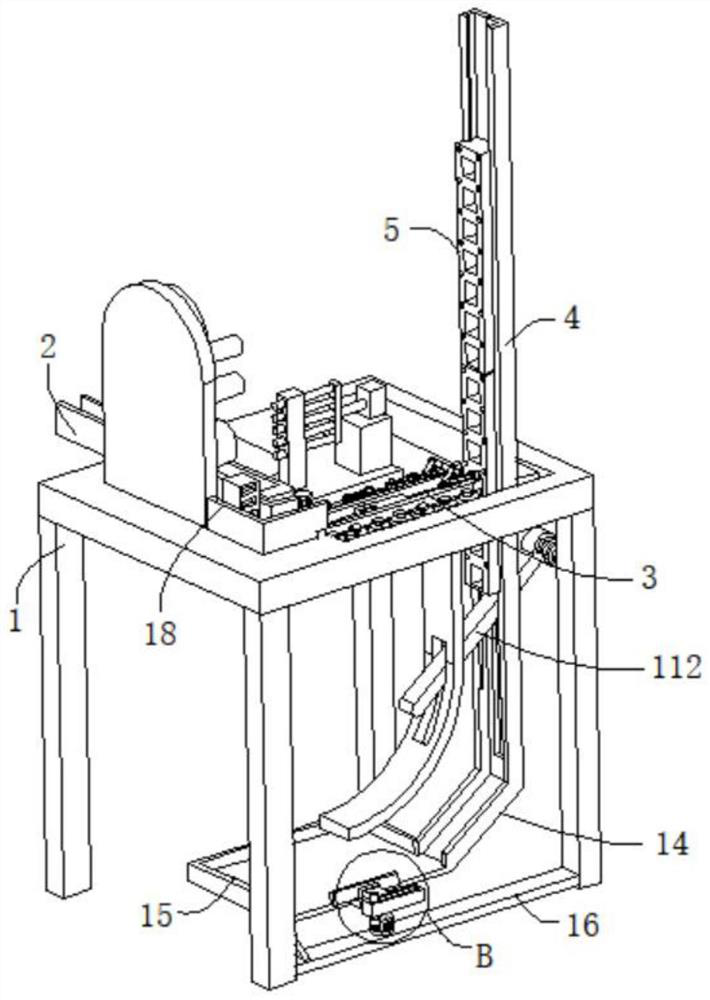

[0034] refer to Figure 1-7 , a lighter wrapping device with automatic loading and unloading functions, comprising a frame 1, the outer wall of the frame 1 is provided with a wrapping device 18 for wrapping lighters, and the two sides of the wrapping device 18 are respectively connected with feeding channels 2 and the discharge channel 3, the feed channel 2 is provided with a conveyor belt, the outer wall of the discharge channel 3 is provided with a conveying mechanism, the inner wall of the frame 1 is connected with a blanking plate 4 through a connecting plate, and the inner wall of the blanking plate 4 is movably connected with several Placement plate 5, the outer wall of the placement plate 5 is provided with evenly distributed placement grooves 501 for placing lighters, the outer wall of the discharge channel 3 is provided with a feeding mechanism, and the outer wall of the placement plate 5 is dug with a limit hole 502 that matches the feeding mechanism .

[0035] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com