Frozen beverage added with water chestnut and preparation method for frozen beverage

A technology of frozen drinks and honey stains, applied in the field of frozen drinks with water chestnut and its preparation, can solve the problems of lack of ice cream, etc., and achieve the effect of filling the gap in the market and enriching the category

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares honey-soaked water chestnut

[0034] 1. Choice of Ling, including:

[0035] Take a look: see if the color is bright, you can't choose the color that is dark, and the outer skin is worn;

[0036] 2. Smell: Smell whether the smell has the smell of stinky sludge. Because water chestnut grows on the water surface, fresh ones cannot have a smell of stinky sludge. If there is a peculiar smell, it means that the water chestnut has deteriorated and the quality is not good;

[0037] 2. Treatment of water chestnut: select fresh water chestnut, soak and peel after peeling to obtain water chestnut meat, wherein the soaking water is treated with cation exchange resin or electrodialysis;

[0038] Processing water: treated with cation exchange resin or electrodialysis to minimize the content of iron ions in the water (it will turn black when it encounters iron ions);

[0039] After the water chestnut is peeled off, it is immersed in 3% salt water to ensure th...

Embodiment 2

[0044] Embodiment 2 prepares water chestnut slurry

[0045] Wash the water chestnut meat before honey soaking in Example 1, beat the water chestnut with a weight ratio of 1:1 to 2:1 to obtain water chestnut pulp for later use.

Embodiment 3

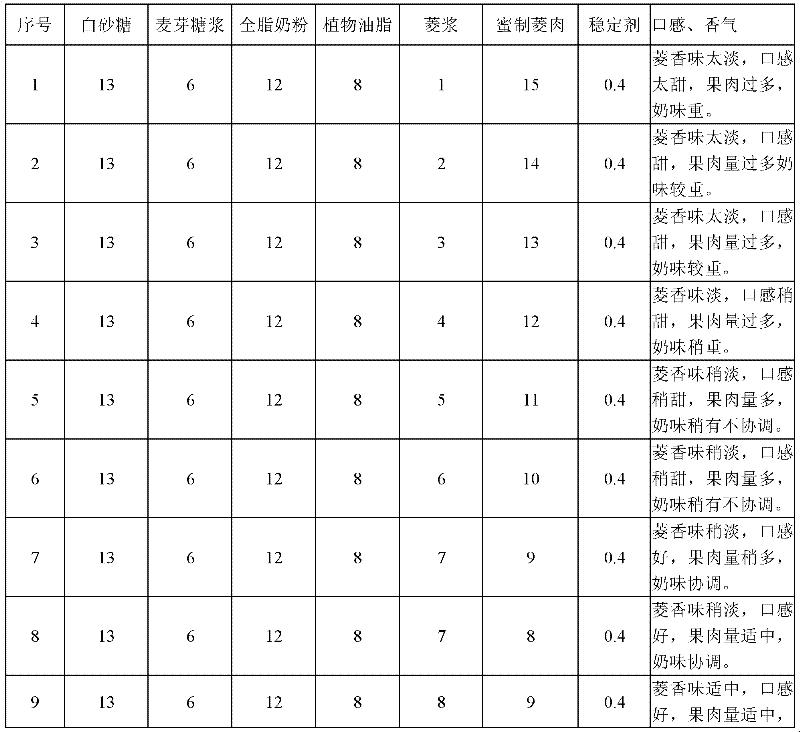

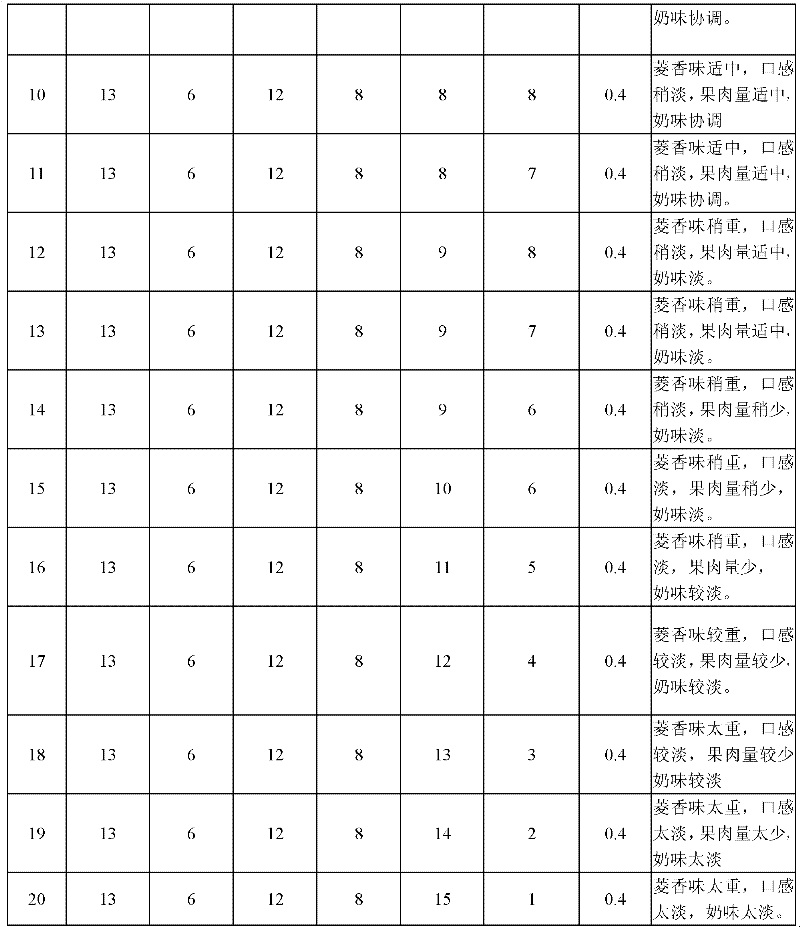

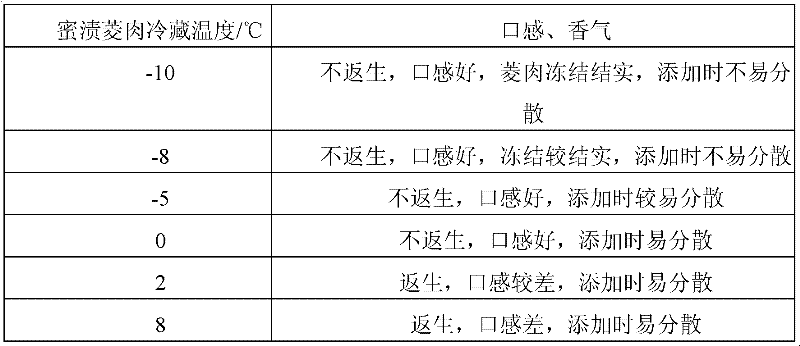

[0046] Embodiment 3 prepares the frozen drink that adds water chestnut

[0047] The raw material formula includes by mass ratio: 20% white granulated sugar, 18% whole milk powder, 10% vegetable oil, 10% maltose syrup, 15% water chestnut pulp, 15% honeydew water chestnut meat, 0.5% edible stabilizer (guar gum: 0.2 %, sodium carboxymethylcellulose: 0.15%, monoglyceride: 0.15%), water balance;

[0048] The preparation method comprises the following steps:

[0049] Raw material pretreatment: mix the above-mentioned stabilizer with white granulated sugar evenly;

[0050] Mixing: In the order of liquid first, then powder, fully mix the raw materials and water evenly, and the mixing temperature is 60°C;

[0051] Preheating: heat the mixed material liquid from the mixing temperature to 70-75°C, and set aside;

[0052] Sterilization: Use a plate heat exchanger to convect the hot water at 90-95°C with the homogenized feed liquid to raise the temperature of the feed liquid to 85-90°C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com