Method for installing telescopic shifting finger sleeve of harvester cutting table drum and telescopic shifting finger device

An installation method and harvester technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problem that the ear of grain cannot be turned out again, and achieve the effect of reducing the ear of grain and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

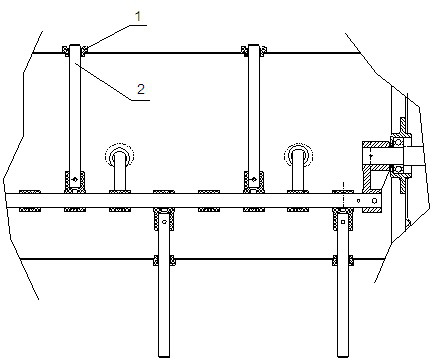

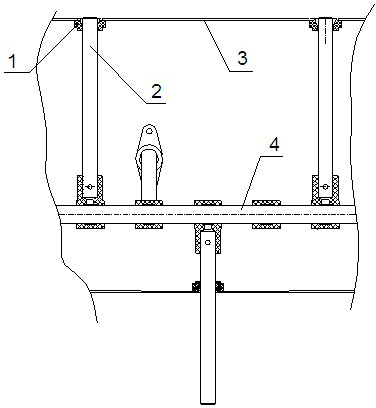

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] attached figure 2 An embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to an installation method of the retractable finger cover of the header drum of a harvester. The telescopic finger cover is placed on the telescopic finger, and the telescopic finger cover is installed simultaneously On the harvester header drum, it is characterized in that the telescopic finger sleeve is installed from the inner surface of the harvester header drum to the harvester header drum wall. This will reduce the taking out of ears of grain, reduce repeated work, thereby reducing the power loss of the harvester and reaching the basic purpose of the present invention.

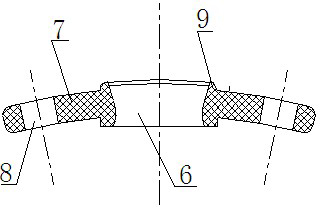

[0024] As a further improvement of the present invention: the top of the telescopic dial finger sleeve has a slit, and the outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com