Waterproof structure

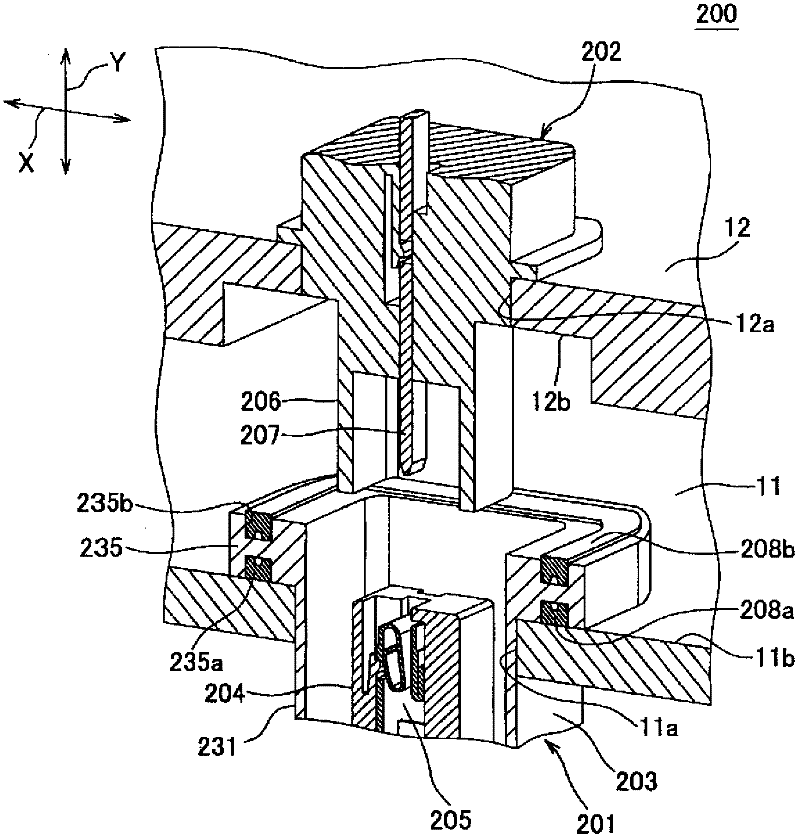

A structural and watertight technology, applied in the direction of two-part connection devices, electrical components, base/housing, etc., can solve the problems of damage to the connector 201, excessive stress, and the reduction of the waterproof performance of the second filler 208b, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

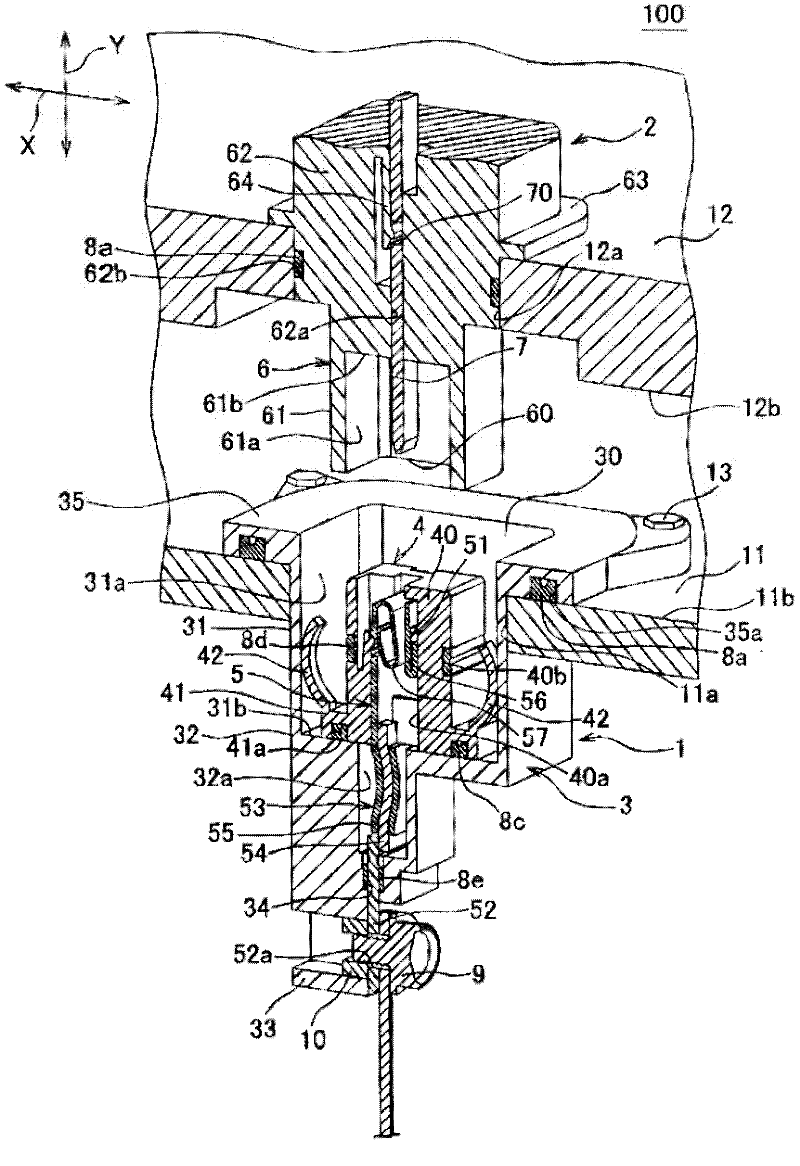

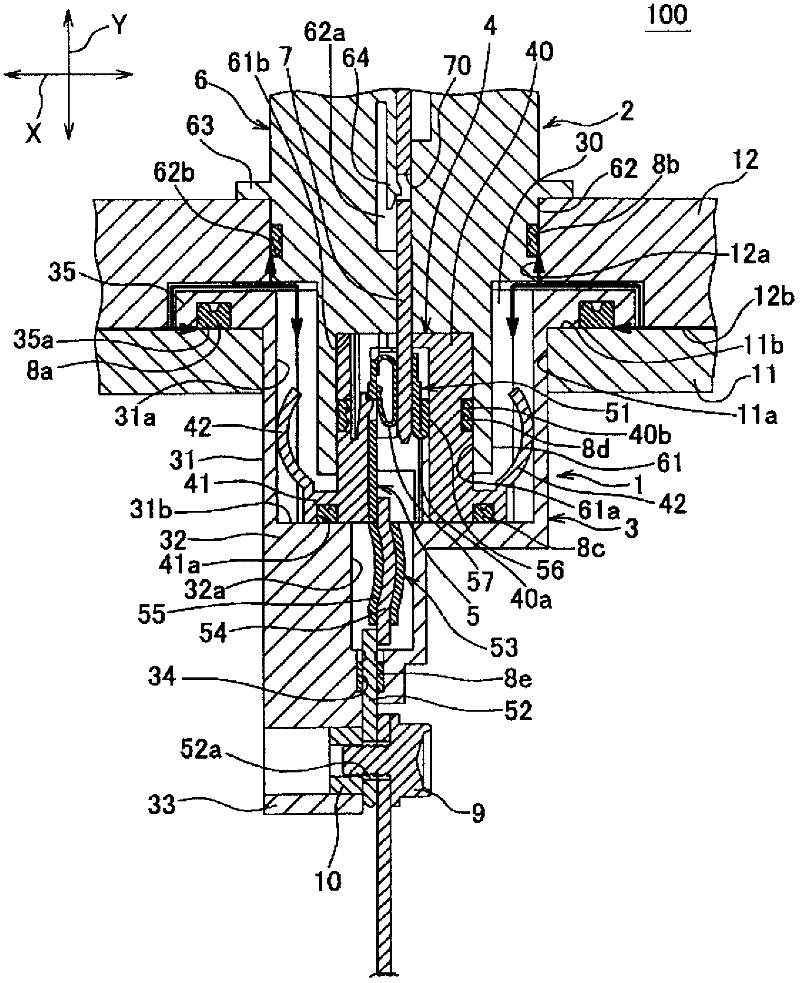

[0041] Below, refer to figure 1 as well as figure 2 , while describing the waterproof structure according to one embodiment of the present invention.

[0042] The above-mentioned waterproof structure 100 is fixed to the connector 1 in the mounting hole 11a of the metal case 11 of the motor mounted on the automobile and in the mounting hole 12a of the metal case 12 of the inverter. In the structure in which the connectors 2 are fitted, the interior of the respective boxes 11, 12 and the interior of the terminal accommodating portions 4, 61 of the respective connectors 1, 2 are waterproofed. That is, the waterproof structure 100 is a waterproof structure in a structure in which the connectors 1, 2 fixed to the boxes 11, 12 are directly fitted to each other when the inverter is mounted on the motor. In addition, "the housing 11" corresponds to "one housing" described in a claim, and "the housing 12" corresponds to "the other housing". In addition, "connector 1" corresponds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com