Heating element

A technology of heating elements and heating zones, applied in the direction of furnace heating elements, heating element materials, electric furnace heating, etc., can solve problems such as terminal connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

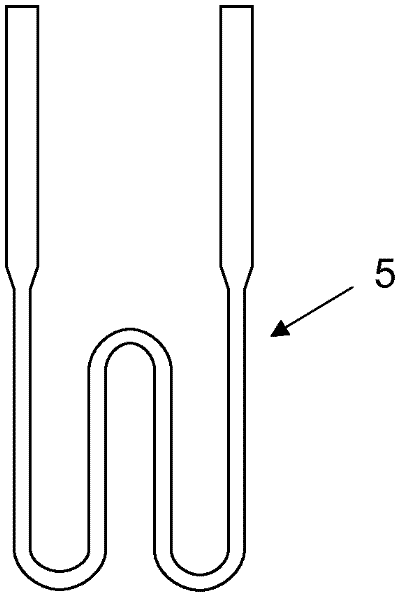

[0026] figure 1 An embodiment of a heating element 1 is shown comprising a heating zone 3 and two terminals 2 in each end of the heating zone 3 . The heating element 1 shown is a two-handled U-shaped heating element. However, the heating element of the invention may also have other shapes, for example a four-handled heating element, a helical heating element or a heating element with a straight heating zone. A heating element may also have more than one heating zone and more than two terminals. Additionally, the heating zone may be divided into a plurality of heating zones.

[0027] exist figure 1 , the terminals 2 each have a diameter D that is larger than the diameter d of the heating zone. It should however be noted that the terminal 2 may have substantially the same diameter as the heating zone 3 .

[0028] As disclosed above, molybdenum disilicide-based materials comprising an oxide phase were previously known for use as heating elements. Other non-conductive compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com