Online checking method for high-tension current transformer

A technology of high-voltage current and calibration method, which is applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve the problems that have not been mentioned in the online calibration of current transformer content, and achieve good real-time performance, high accuracy, and improved reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the invention will be further described below in conjunction with the accompanying drawings:

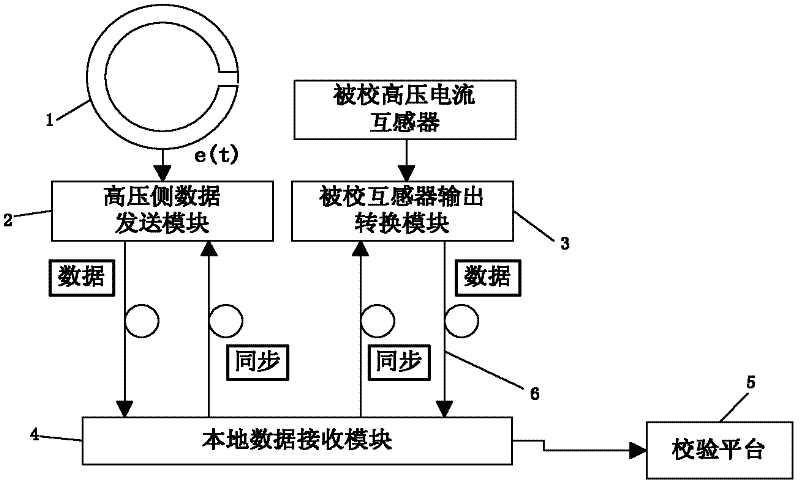

[0019] Such as figure 1 As shown, the present invention consists of a standard channel, a checked channel and a verification platform. The standard channel mainly includes the standard current sensor 1, the high-voltage side data sending module 2, the calibrated channel includes the calibrated transformer output conversion module 3 and the local data receiving module 4, the calibration platform 5 is composed of industrial computer and virtual instrument software, 6 Optical fiber for data transmission.

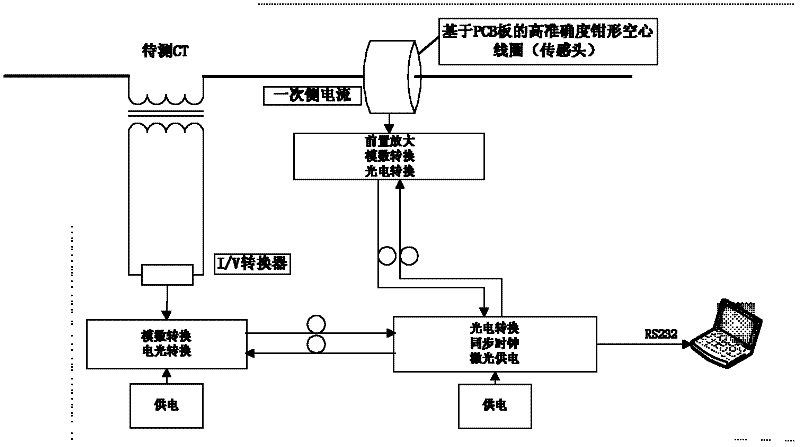

[0020] Such as figure 2 As shown, the present invention is a device for verifying various parameters of the calibrated high-voltage current transformer operated on site by comparing the output values at the same time between the standard current sensor with known accuracy and the calibrated high-voltage current transformer. Its working principle is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com