Apparatus for testing work ability of activated carbon canister used for vehicle

A technology of working ability and test device, applied in the direction of using material absorption and weighing, and weighing by removing certain components, it can solve the problems of low degree of automation and low test accuracy, and achieve accurate and effective evaluation, convenient operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

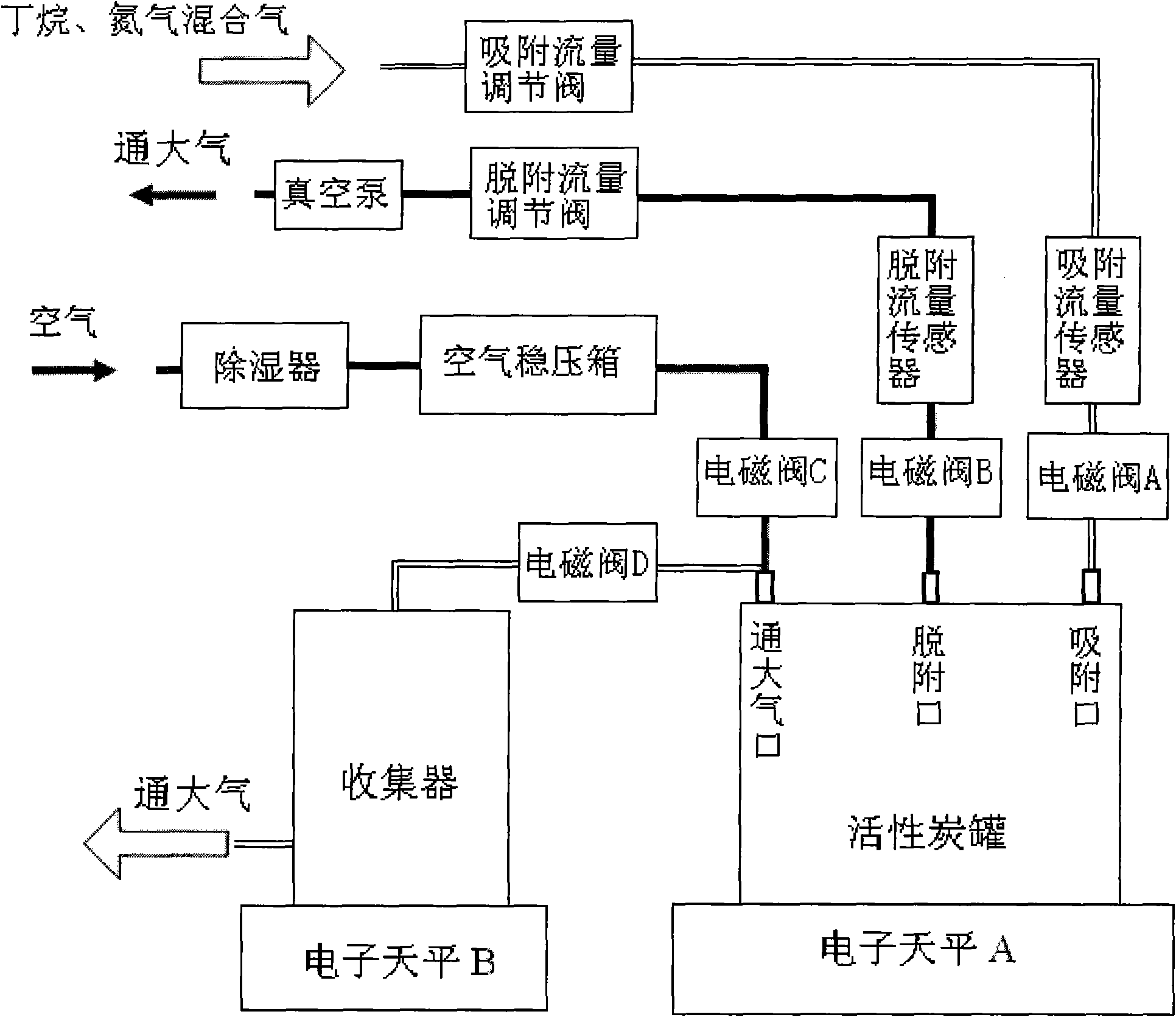

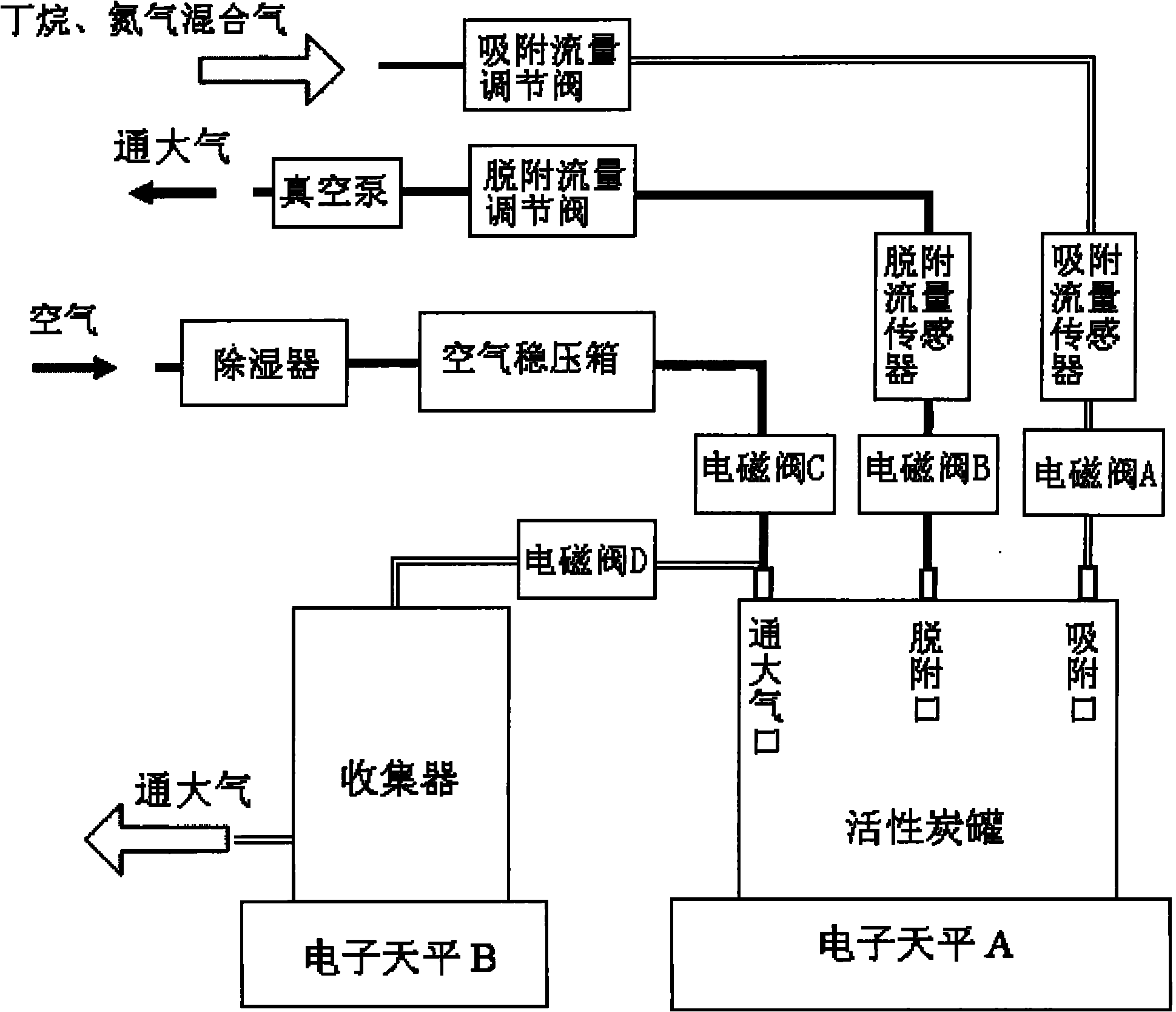

[0018] Below, according to the limitation of the national standard HBC32-2004 on the working capacity test procedure of the activated carbon canister, in conjunction with the accompanying drawings, the embodiments of the present invention will be further described.

[0019] Such as figure 1 As shown, the test steps are as follows:

[0020] 1. At the beginning of the test, the electronic balance A weighs the activated carbon tank and sends it to the computer measurement and control system for recording;

[0021] 2. Adsorption test: Use a mixture of 50% volume butane and 50% volume nitrogen to conduct an adsorption test on the activated carbon tank. At this time, control solenoid valve A and solenoid valve D to open, solenoid valve B and solenoid valve C to close, and conduct the adsorption test. The pipeline is connected, and the mixed gas is adsorbed on the activated carbon tank and enters the atmosphere through the adsorption flow regulating valve, adsorption flow sensor, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com