Three-way joint for connecting pipes

A technology of tee joints and pipes, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of fastener connection failure, thin metal plate structure, and reduce assembly efficiency, etc., to simplify installation operations and simple structure , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

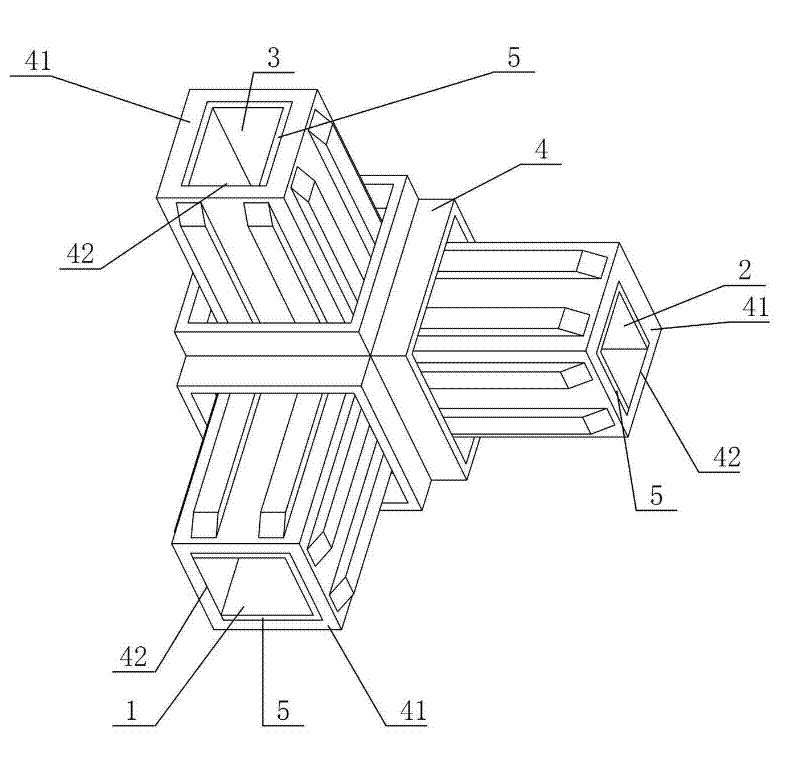

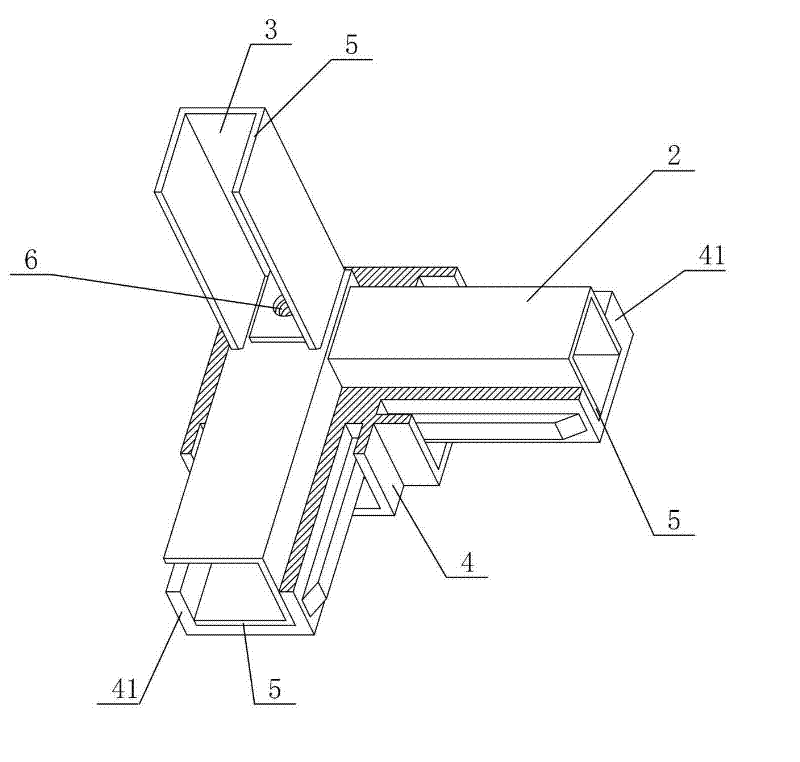

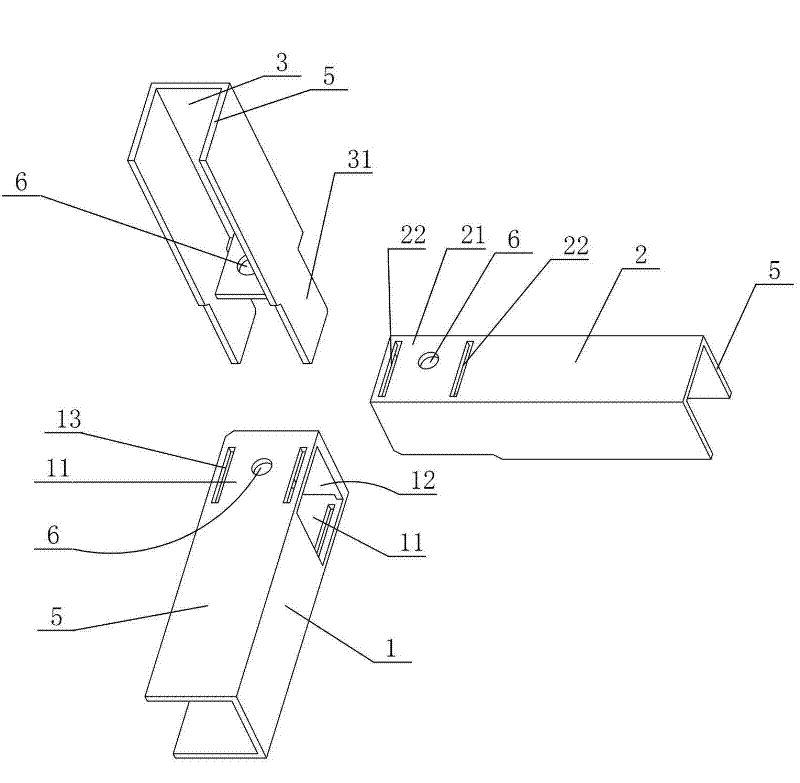

[0025] Figure 1 to Figure 3 It shows an embodiment of a tee joint for pipe connection of the present invention, the tee joint is composed of a nylon tee joint body 4 and three pieces of metal parts, and the nylon tee joint body 4 is provided with three sections for connecting pipes The three-section joint 41 is respectively provided with an inner hole 42, and the three inner holes 42 communicate with each other, and each inner hole 42 is inserted into a piece of metal, and each metal piece includes a base part and an interspersed connection part, and the three metal pieces Through the interpenetration and connection of the respective interspersed connection parts to form a whole, it is no longer necessary to install fasteners to connect the metal parts, which not only simplifies the installation operation, improves the assembly efficiency, saves labor costs, but also ensures the connection strength. When a single metal When the parts are subjected to torsion, they can resist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com