Engine valve lift variable device

An engine valve, variable technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of poor switching reliability, large moment of inertia and damping loss, etc., to achieve high reliability, reduce moment of inertia and damping Loss, improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, refer to the attached Figure 1-9 The specific embodiment of the present invention is described:

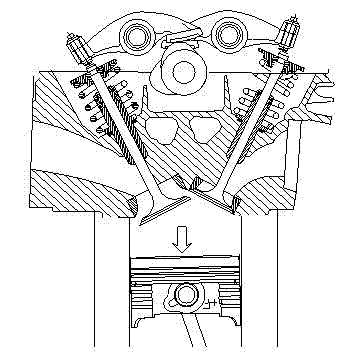

[0036] Such as figure 1 As shown, the intake valve of the traditional internal combustion engine is controlled by a cam, and the lift of the valve is not variable.

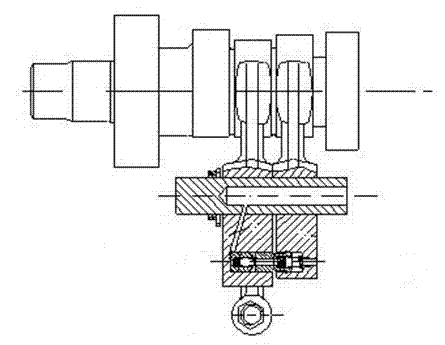

[0037] Such as figure 2 As shown, the engine valve lift variable device in the prior art, the high-speed intake cam and the low-speed intake cam usually use two or more rocker arms to realize the opening and closing control of the intake valve, although this structure is to a certain extent The air intake adjustment of the engine has been changed, but due to the problems of large moment of inertia and damping loss of multiple rocker arms, and poor reliability of switching between high and low speed intake cams, the performance of the engine cannot be fundamentally changed.

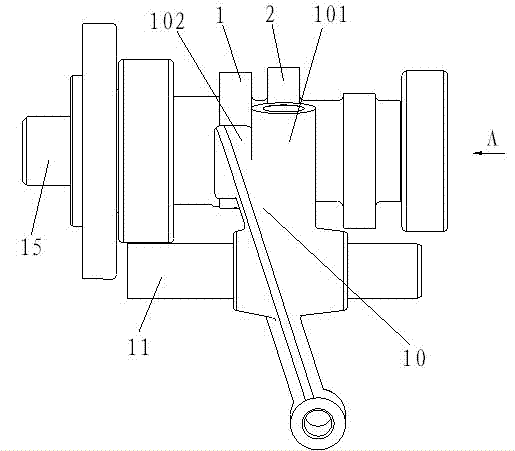

[0038] Such as image 3 As shown, the engine valve lift variable device of the present invention adopts the structure of a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com