A mine filling pipeline automatic switching device

An automatic switching and mine filling technology, which is applied in the direction of fillings, safety devices, pipe components, etc., can solve the problems of time-consuming and labor-intensive, low reliability, etc., and achieve the effect of low failure rate, simple structure, fast and reliable switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

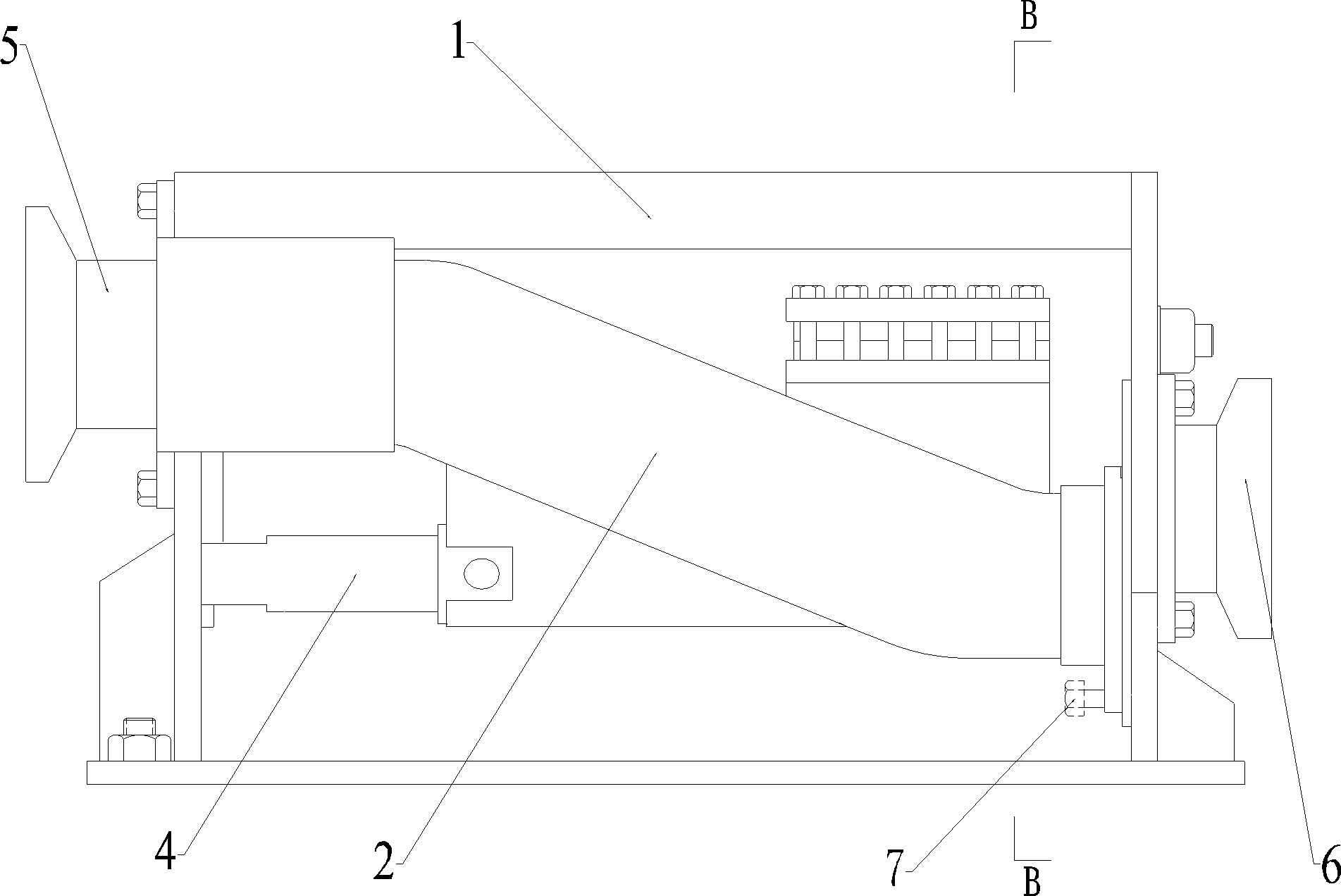

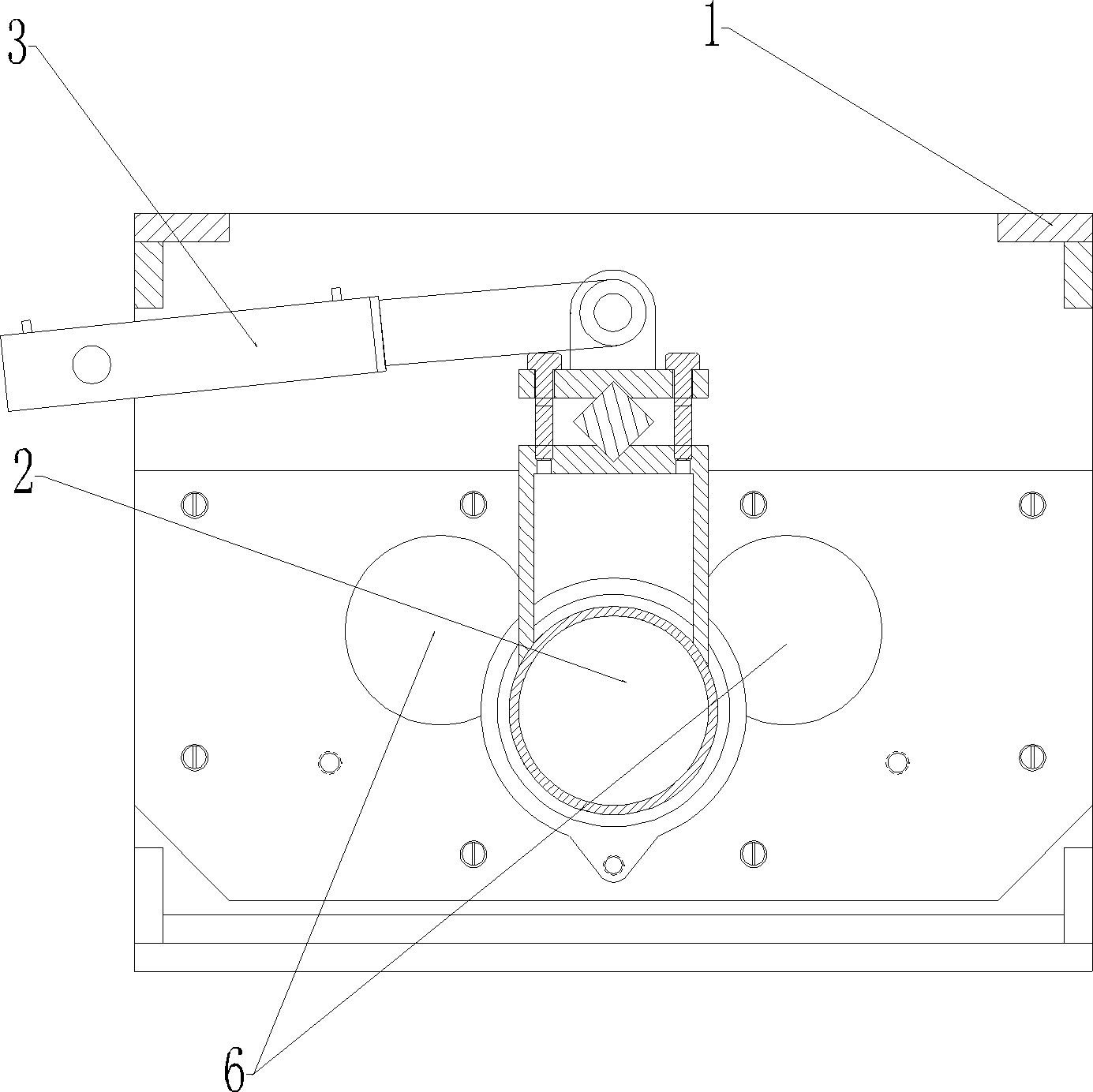

[0019] See attached Figure 1-2 , Which describes a preferred embodiment of the automatic switching device for mine filling pipelines according to the present invention. The automatic switching device of the mine filling pipeline includes a bracket, a connecting pipe, a swing pipe cylinder and a compression cylinder; the bracket is a basically rectangular metal frame welded by angle steel, steel pipe or other section steel, and the connecting pipe, the swing pipe cylinder and the compression cylinder are all Set inside the bracket, one end of the bracket is provided with a feed port, and the other end is provided with two discharge ports; the inlet end of the connecting pipe is fixedly connected with the feed port and communicates with the feed port, and the outlet end of the connecting pipe is connected There is a swing tube cylinder. The extension and contraction of the piston rod of the swing tube cylinder can freely move the outlet end of the connecting pipe within a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com