Drilling tool

A drilling tool and drill bit technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve problems such as bolt damage, drill drop accidents, bolt loosening, etc., and achieve the effect of reducing drill drop accidents and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

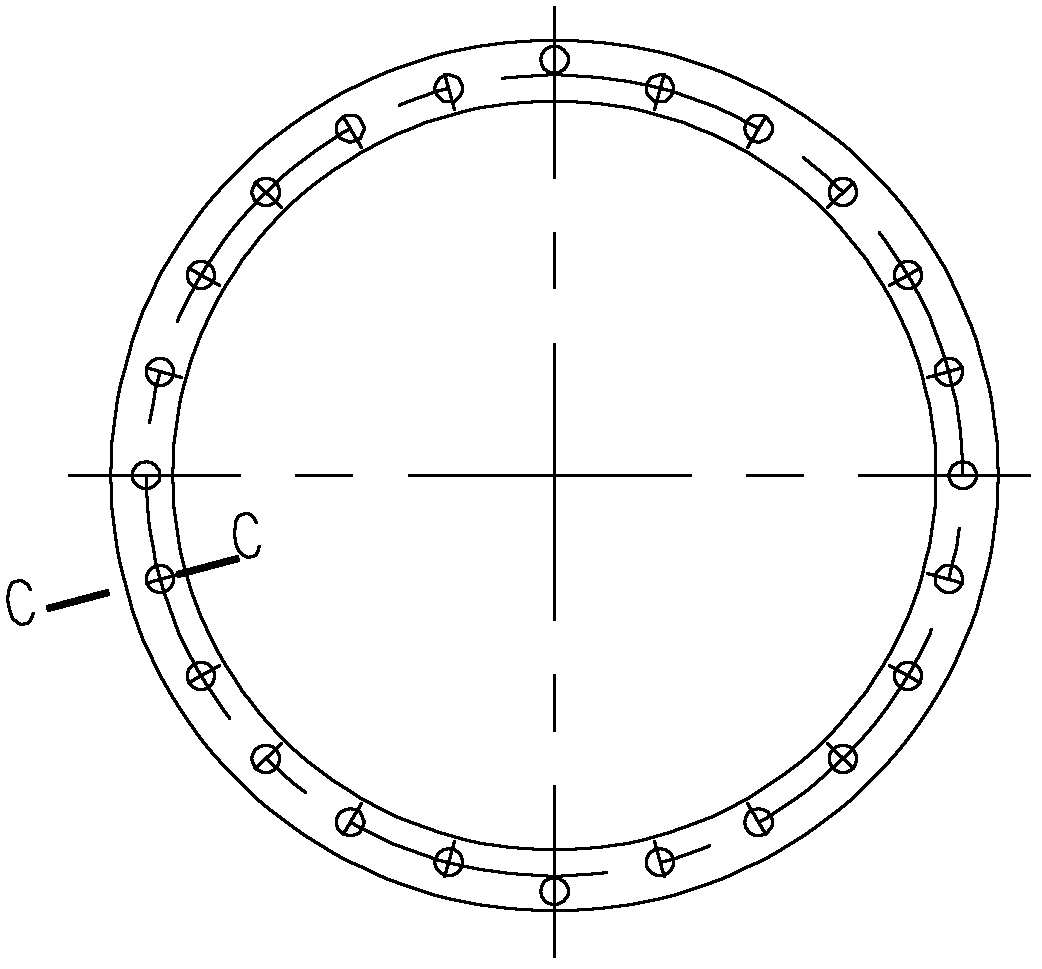

[0028] see image 3 and Figure 4 As shown, a drilling tool according to an embodiment of the present invention includes a drill rod 10 and a drill bit 20 connected to the drill rod, and the drill rod 10 and the drill bit 20 each have flange connection plates 11 and 21;

[0029] At least two openings 12 and 22 are respectively opened on the flange connecting disks 11 and 21 of the drill rod and the drill bit, and the opening direction of the opening faces away from the center of the flange connecting disk; The flange connection plate of the drill bit also has at least two pin holes respectively; The opening 12 and the pin hole on the drill bit correspond to the opening 22 and the pin hole on the flange connection plate of the drill bit; an I-shaped card 30 is arranged in the corresponding opening; the I-shaped card 30 connects the flange connection plates 11 and 21 of the drill rod and the drill bit; a pin shaft 40 for transmitting torque is pierced in the corresponding pin ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the drill bit is not directly connected to the drill rod, but is connected to the drill rod through a drill guide.

[0036] see Figure 6 and Figure 7 As shown, the drilling tool of this embodiment includes a drill rod 10, a drill guide 50 connected to the drill rod, and a drill bit 20 connected to the drill guide 50; the drill rod and the drill bit each have a flange connecting plate; the upper end and the lower end of the drill guide also have flange connecting plates respectively; 11 shown in the figure is the flange connecting plate of the drill rod; the flange connecting plate of the drill rod, the drill bit guide and the drill bit There are at least two openings on each, and the opening direction of the openings is away from the center of the flange connection plate; Figure 8 Shown in 12 is the opening on the flange connection plate of drill rod; Also offer at least two pin holes respectively on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com