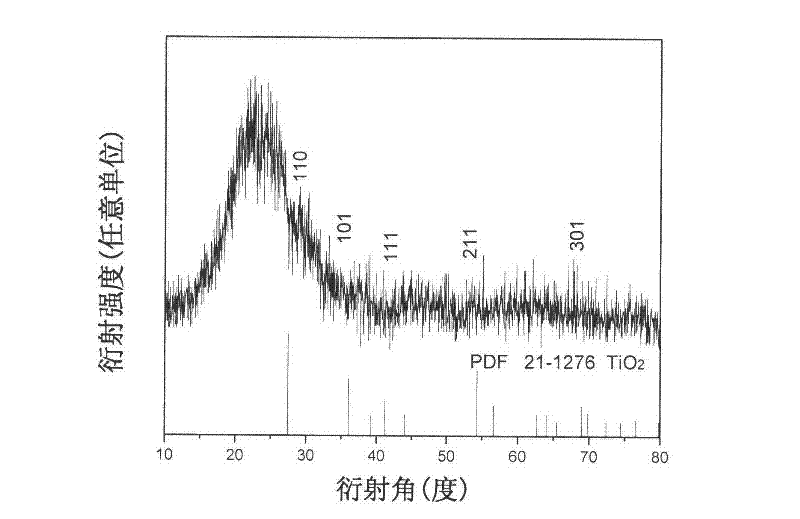

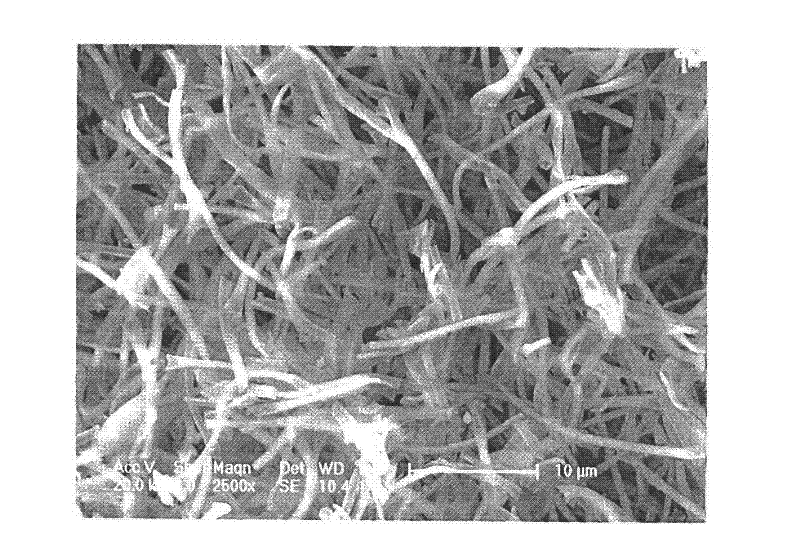

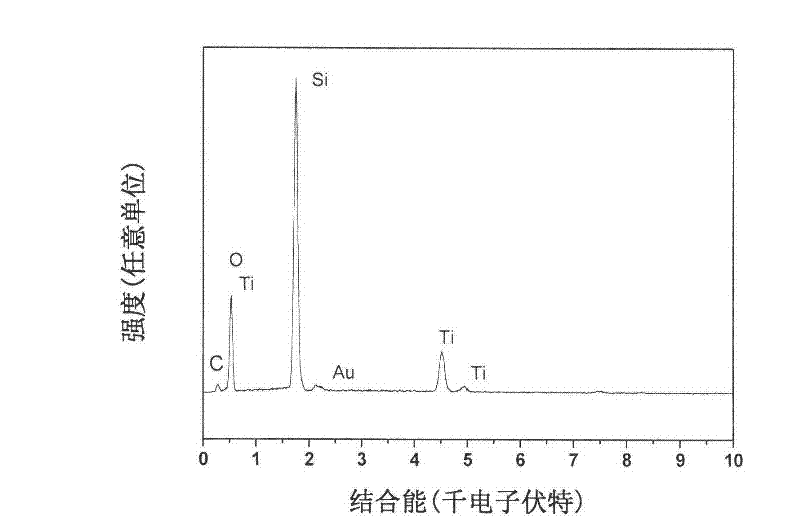

Method for preparing TiO2@SiO2 coaxial nanotube

A technology of silicon dioxide and titanium dioxide, which is used in the preparation of spinning solutions, chemical characteristics of fibers, conjugated artificial filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example: After stirring a mixture of sesame oil and sorbitan oleate Span-80 at a volume ratio of 1:1 at room temperature for 3 h, an equal volume of butyl titanate Ti(OC 4 h 9 ) 4 , continue to stir for 6 hours and then stand still for 3 hours to obtain a uniform [sesame oil+Span-80+Ti(OC 4 h 9 ) 4 ] mixed solution, as the middle layer spinning solution, wherein the mass percentages of butyl titanate, sesame oil and sorbitan oleate are respectively 50.1%, 23.9% and 26.0%; polyvinylpyrrolidone PVP is added to an appropriate amount of water ethanol C 2 h 5 OH and chloroform CHCl 3 After magnetically stirring for 3 hours at room temperature, add a certain amount of ethyl orthosilicate TEOS, continue to stir for 6 hours and then let it stand for 3 hours to obtain a uniform and transparent [PVP+TEOS+C 2 h 5 OH+CHCl 3 ] solution, as the shell spinning solution, wherein the mass percentages of PVP, TEOS, ethanol and chloroform are respectively 8.0%, 14.7%, 61.7% and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com