Combined technology for treatment and recycle of production sewage

A combined process and sewage production technology, which is applied in the directions of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of membrane system pollution, achieve water conservation, reduce Frequency of chemical cleaning, effect of improving influent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

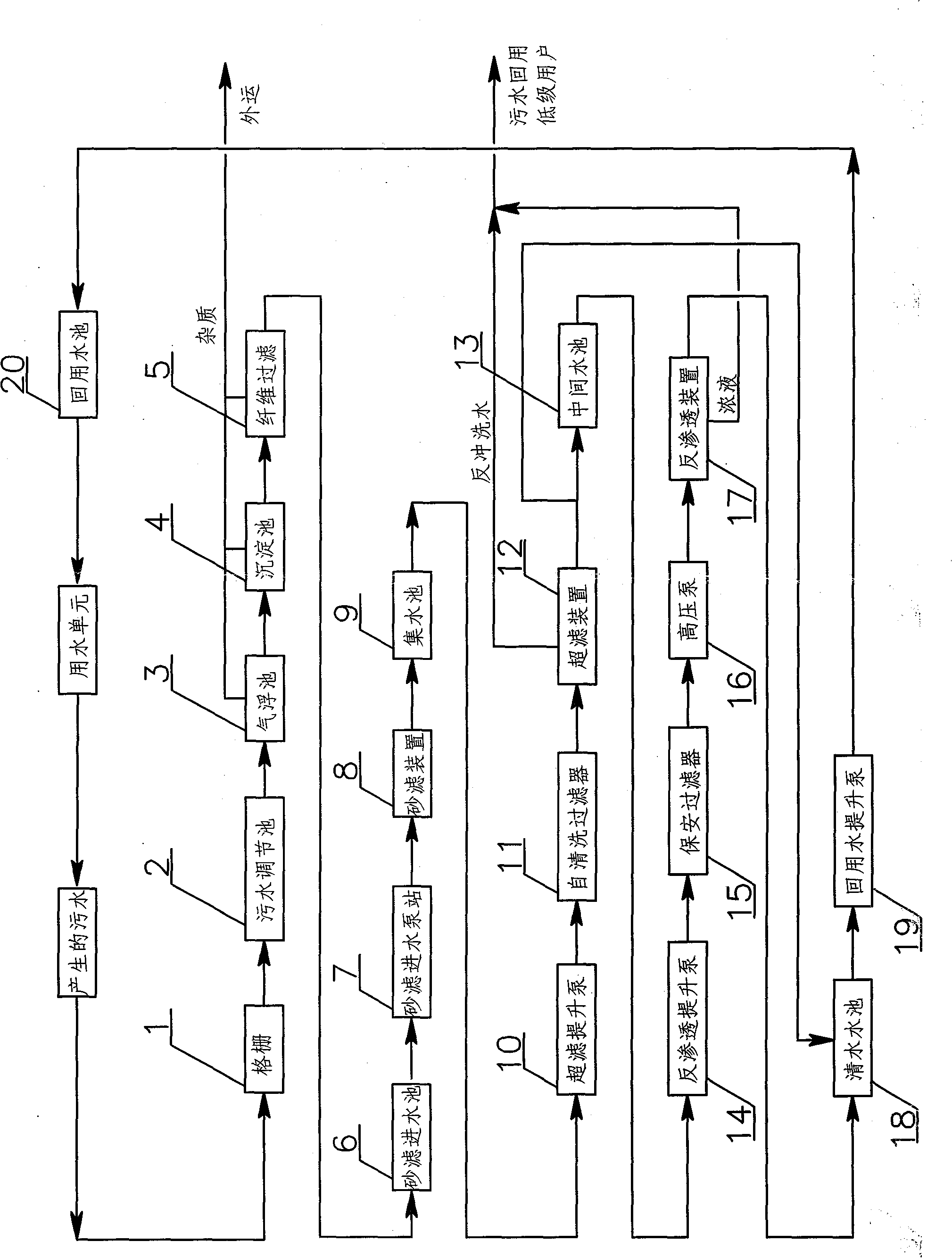

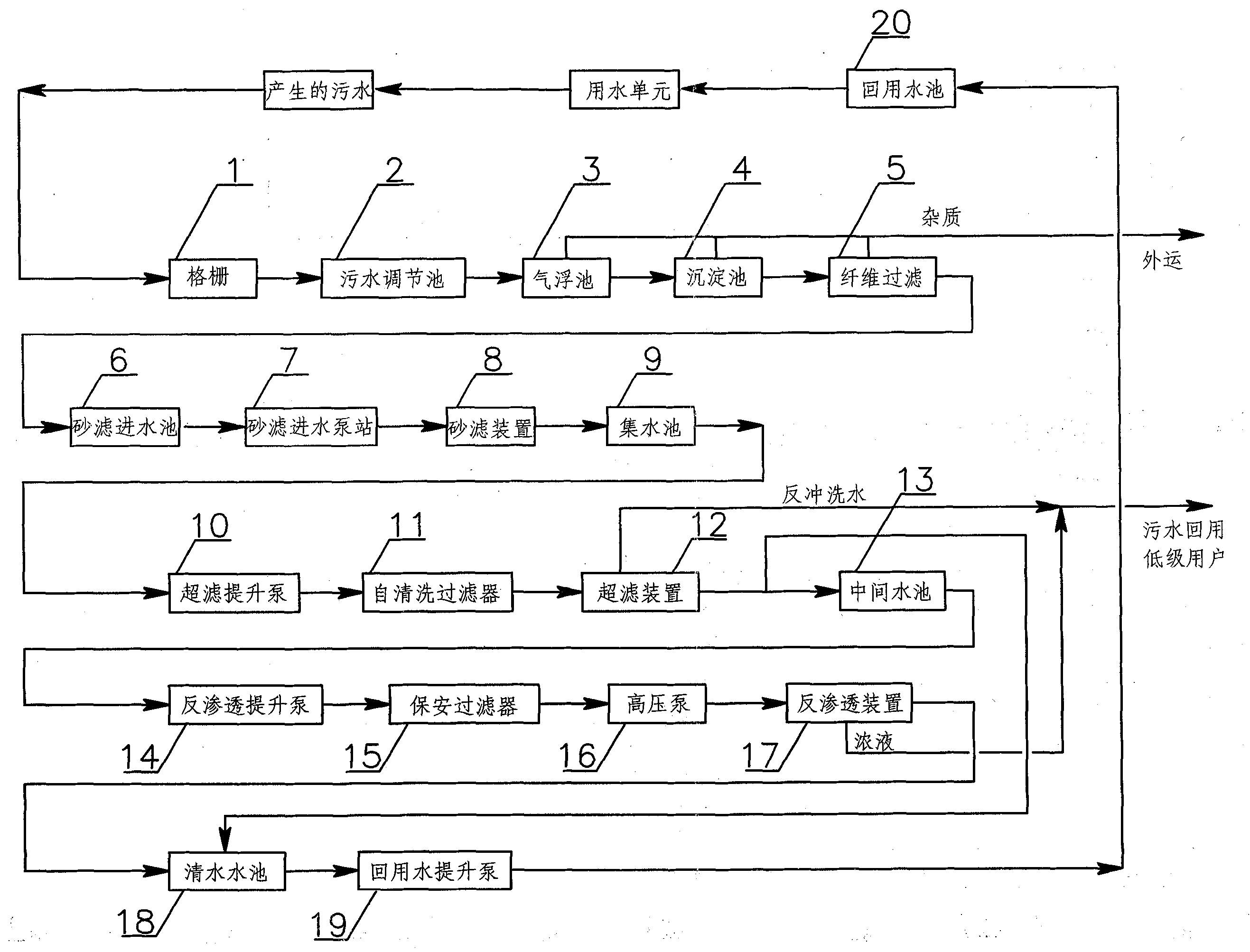

[0021] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0022] As shown in the figure, a combined process for reuse of production sewage after treatment in the present invention is composed of a sewage pretreatment system, a sewage advanced treatment system, and a sewage desalination system, wherein the pretreatment includes a grid 1 and a sewage adjustment tank 2. Air flotation tank 3, sedimentation tank 4, fiber filter 5, advanced treatment by sand filter into water tank 6, sand filter into water pump station 7, sand filter device 8, water collection tank 9, ultrafiltration lift pump 10, self-cleaning filter 11. Composed of an ultrafiltration device 12 and an intermediate pool 13, the sewage desalination treatment system includes a reverse osmosis lift pump 14, a security filter 15, a high-pressure pump 16, a reverse osmosis device 17, a clean water pool 18, a return water lift pump 19 and a reuse Pool 20.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com