Bamboo-wood bottom plate for container and manufacture method thereof

A manufacturing method and container technology, which are applied in the directions of wood layered products, chemical instruments and methods, packaging, etc., can solve the problems of poor floor stability, easy to open layers, and it is difficult to meet the waterproof requirements of container bottom plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

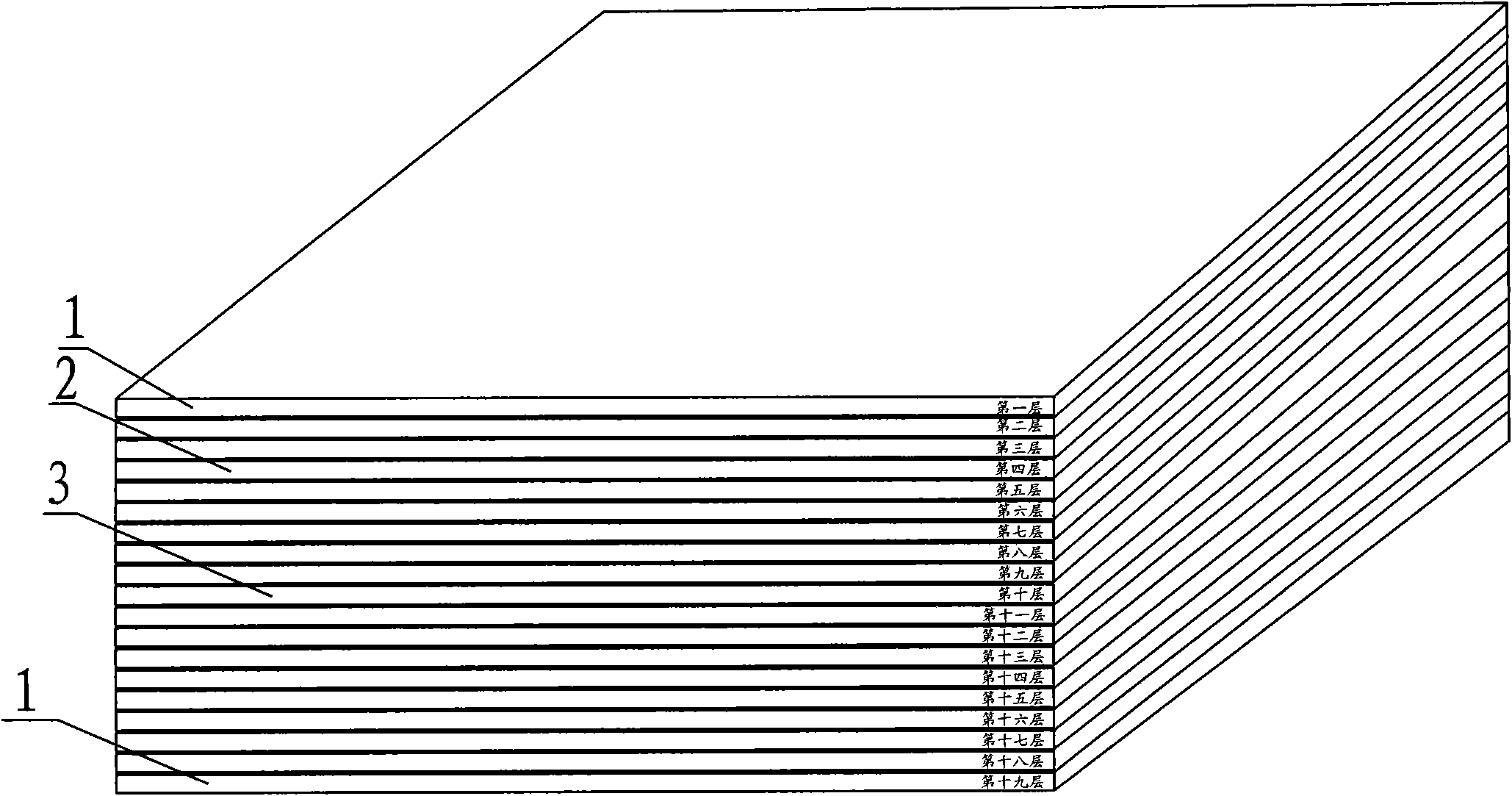

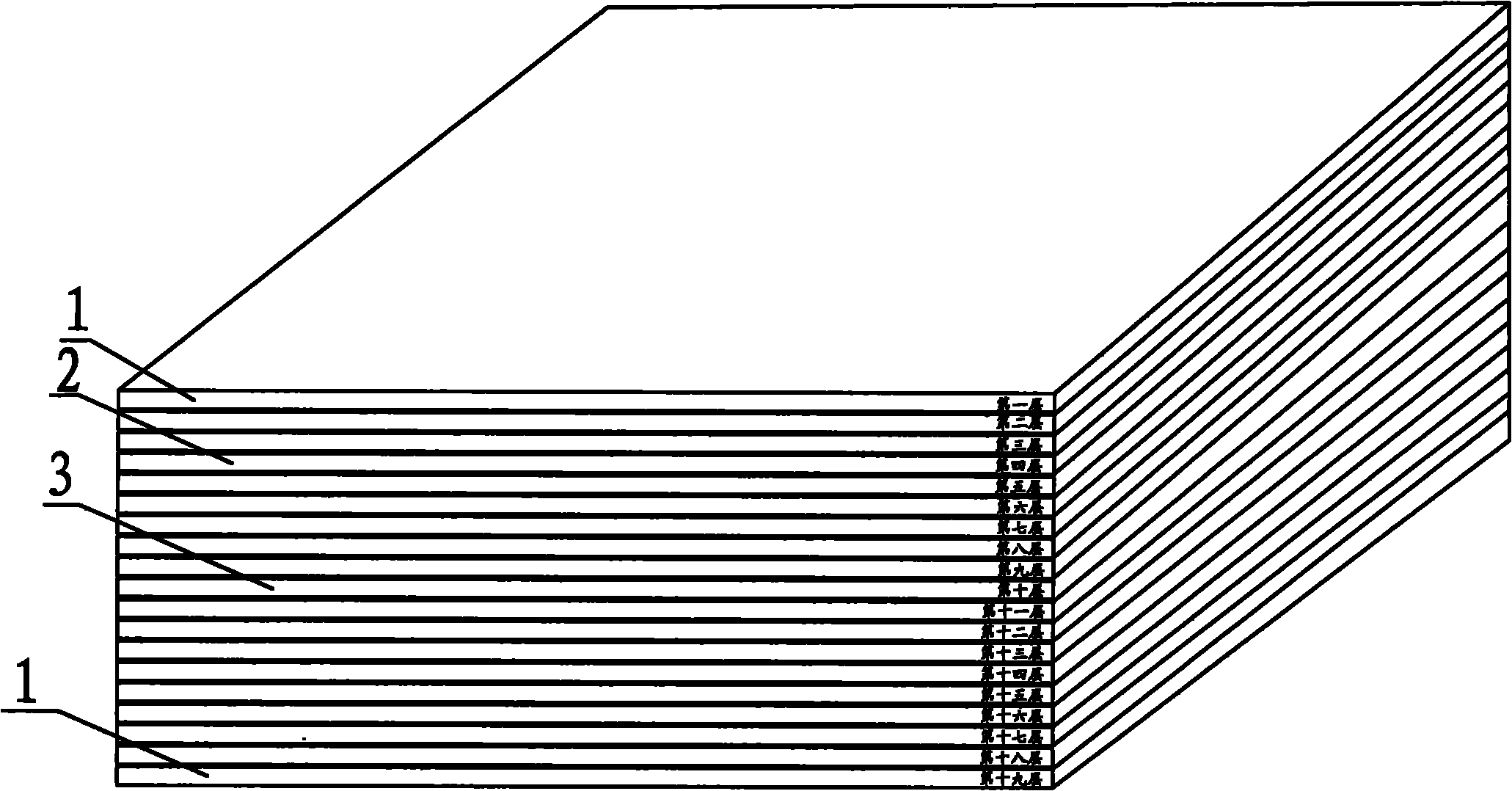

[0022] Embodiment 1: A method for making the bamboo and wood floor of a container. First, the bamboo is broken into bamboo filaments, and then the bamboo filaments are carbonized into carbonized bamboo filaments at a temperature of 200 degrees and in an environment of 2 atmospheres of pressure and high humidity. ; The carbonized bamboo silk is woven into a bamboo silk veneer, wherein the thickness of the bamboo silk veneer is 2.5 millimeters, and a plurality of bamboo silk veneers are glued to form a multi-layer bamboo silk veneer layer; wherein the wood veneer is made of fast-growing Composed of wood, multiple wood veneers are glued to form multi-layer wood veneer layers; multi-layer bamboo silk veneer layers and multi-layer wood veneer layers are combined to form corresponding blanks, and the blanks are pre-prepared. Press waste to repair, after high temperature and high pressure hot pressing, it becomes a bamboo and wood glued floor, so that the bamboo and wood floor of the ...

Embodiment 2

[0023] Embodiment 2: A kind of manufacturing method of container bamboo floor, first break bamboo into bamboo silk, then carbonize bamboo silk under the temperature of 150 degrees, 1.87 atmospheric pressure and high humidity environment to become carbonized bamboo silk ; The carbonized bamboo silk is woven into a bamboo silk veneer, wherein the thickness of the bamboo silk veneer is 3 millimeters, and a plurality of bamboo silk veneers are glued to form a multi-layer bamboo silk veneer layer; wherein the wood veneer is made of fast-growing Composed of wood, multiple wood veneers are glued to form multi-layer wood veneer layers; multi-layer bamboo silk veneer layers and multi-layer wood veneer layers are combined to form corresponding blanks, and the blanks are pre-prepared. Press waste to repair, after high temperature and high pressure hot pressing, it becomes a bamboo and wood glued floor, so that the bamboo and wood floor of the container is produced.

Embodiment 3

[0024] Embodiment 3: A kind of manufacturing method of container bamboo and wood bottom plate, first break bamboo into bamboo silk, then carbonize bamboo silk under the temperature of 230 degrees, 3 atmospheres of pressure and high humidity environment to become carbonized bamboo silk ; The carbonized bamboo silk is woven into a bamboo silk veneer, wherein the thickness of the bamboo silk veneer is 4 millimeters, and a plurality of bamboo silk veneers are glued to form a multi-layer bamboo silk veneer layer; wherein the wood veneer is made of fast-growing Composed of wood, multiple wood veneers are glued to form multi-layer wood veneer layers; multi-layer bamboo silk veneer layers and multi-layer wood veneer layers are combined to form corresponding blanks, and the blanks are pre-prepared. Press waste to repair, after high temperature and high pressure hot pressing, it becomes a bamboo and wood glued floor, so that the bamboo and wood floor of the container is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com